Electrification railway contact net measuring aiming method based on camera

A technology for electrified railways and cameras, which is applied to railway vehicle shape measuring instruments, radio wave measuring systems, measuring devices, etc., can solve problems such as difficulty in precise and rapid aiming, and achieve high aiming accuracy, improve aiming accuracy, and eliminate parallax effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

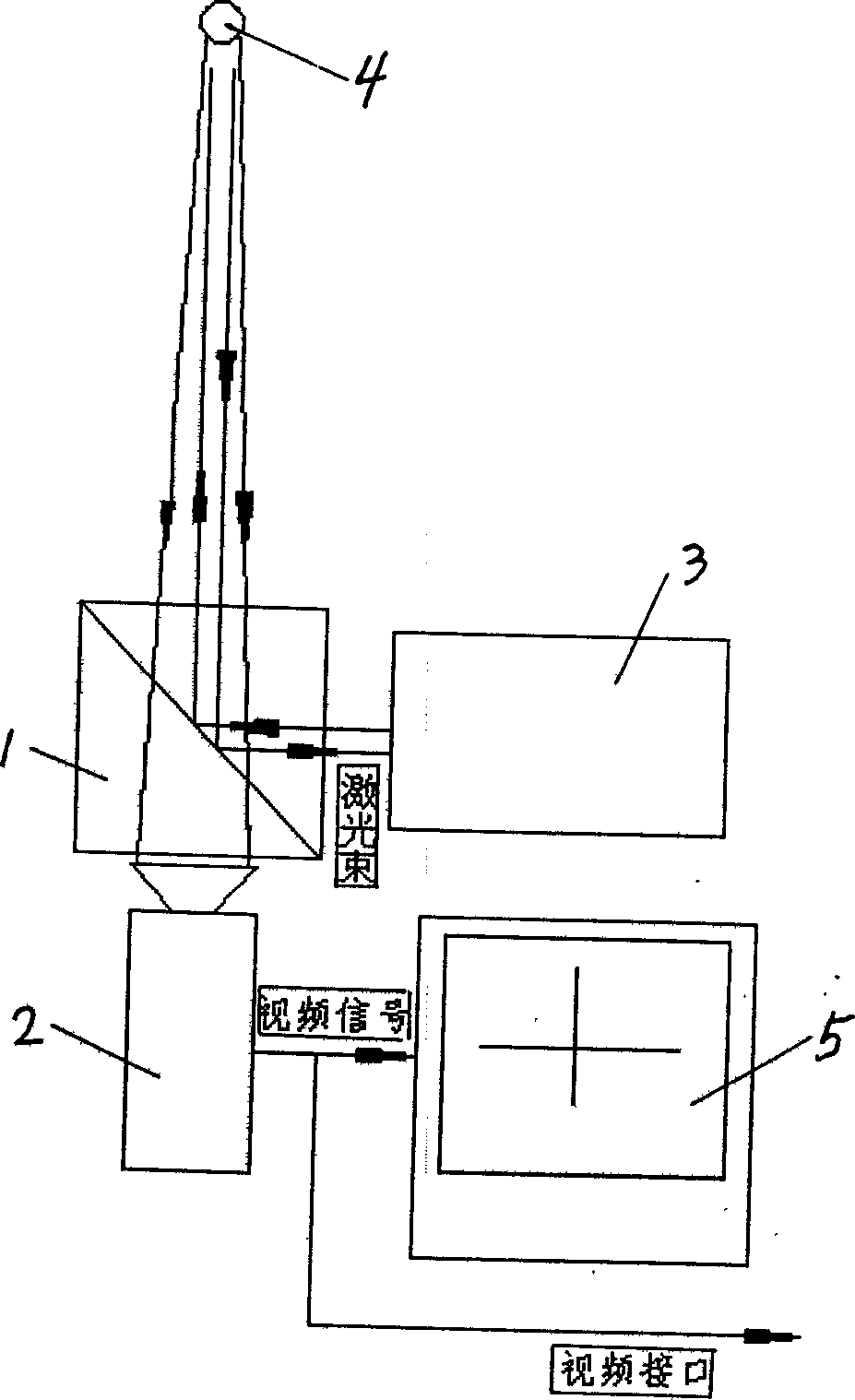

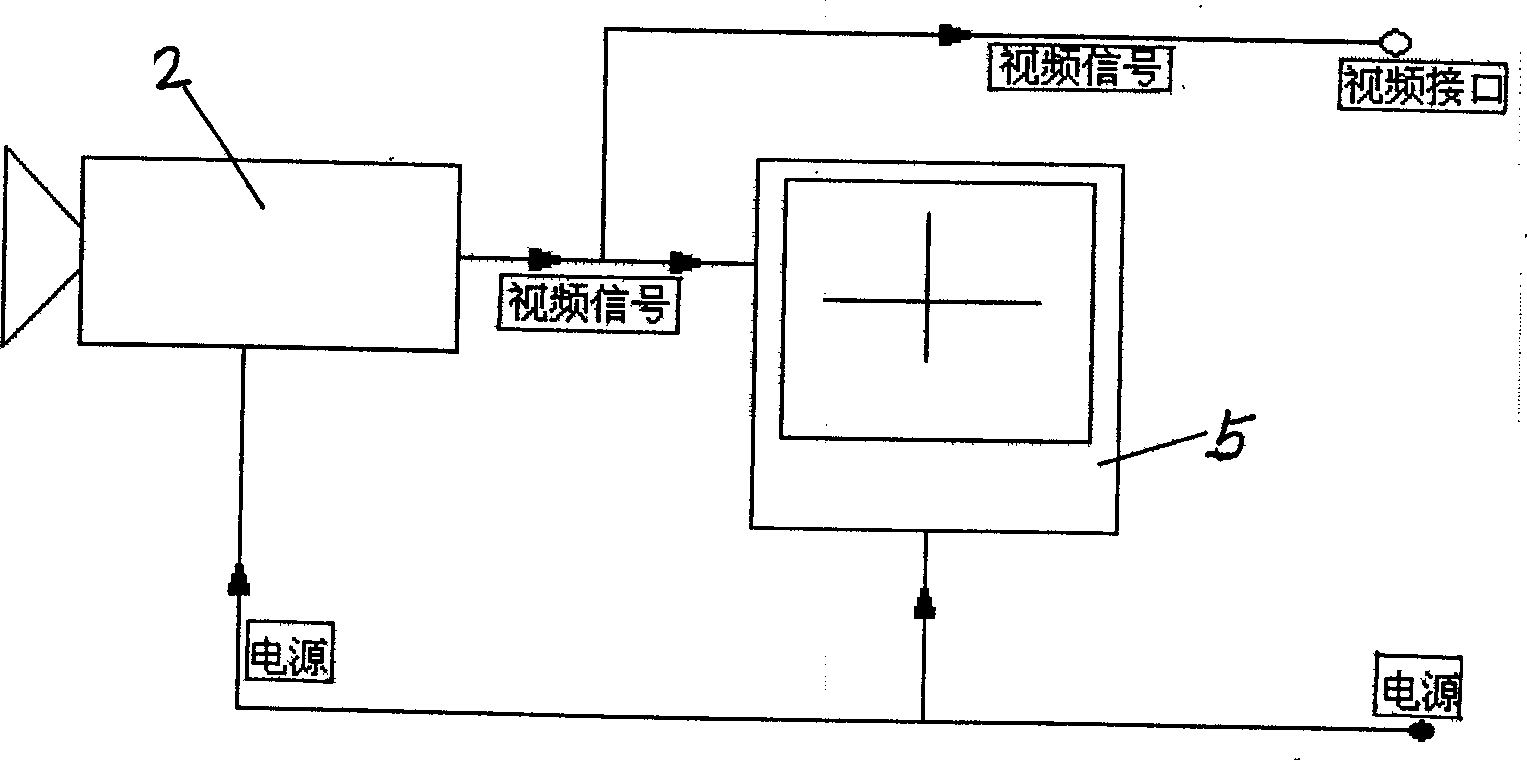

[0013] figure 1 The structural principle diagram of the present invention is given. The aiming method is to place a beam splitting prism 1 on the left side of the laser distance sensor 3 used for measuring catenary line guide height, and make the outgoing light beam of the laser distance sensor 3 perpendicular to the right incident surface of the beam splitting prism 1 . A camera 2 is placed directly below the lower incident surface of the beam splitting prism 1 , and the optical axis of the camera 2 is perpendicular to the lower incident surface of the beam splitting prism and perpendicular to the outgoing beam of the laser distance sensor 3 . The video output of camera 2 is connected with TFT display 5 .

[0014] The image of the electrified railway catenary line directly passes through the beam splitting prism 1 and reaches the camera 2, and the outgoing beam of the laser distance sensor 3 reaches the catenary line through a 90-degree turn. The optical path of the camera ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com