Double sided knitted fabric having variable birib weft plain composite stitch and its weaving technology

A composite weave and rib weave technology, applied in weft knitting, knitting, textiles and papermaking, etc., can solve the problems of warmth retention, insufficient elastic washing size change rate, wet and uncomfortable underwear, etc., achieve small loops, increase breathability Sex, tuck style obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

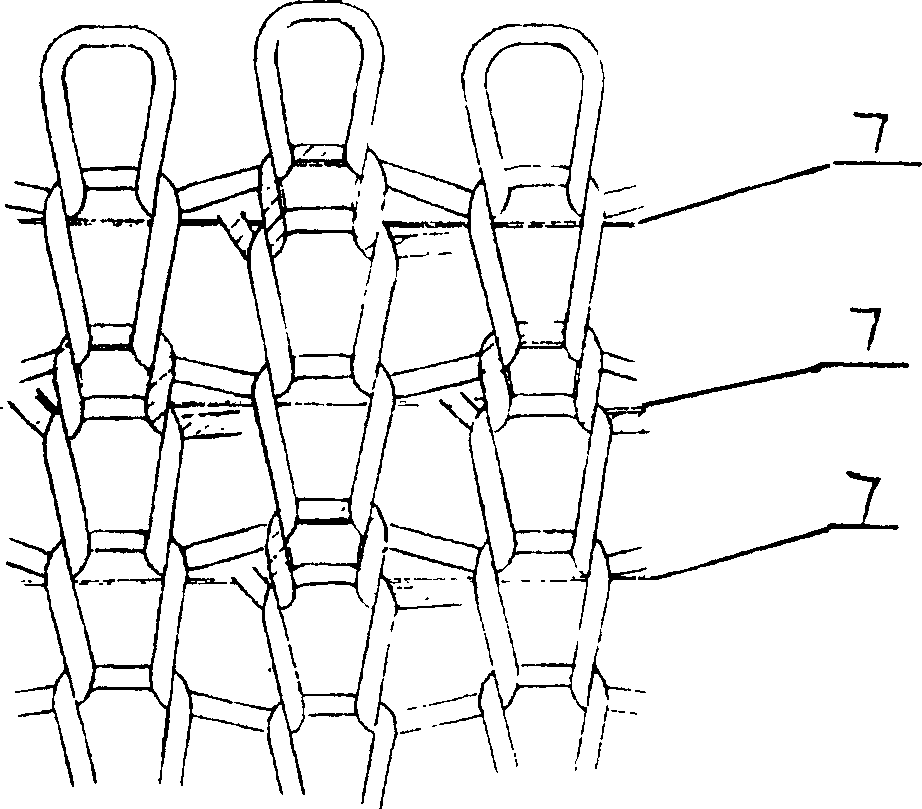

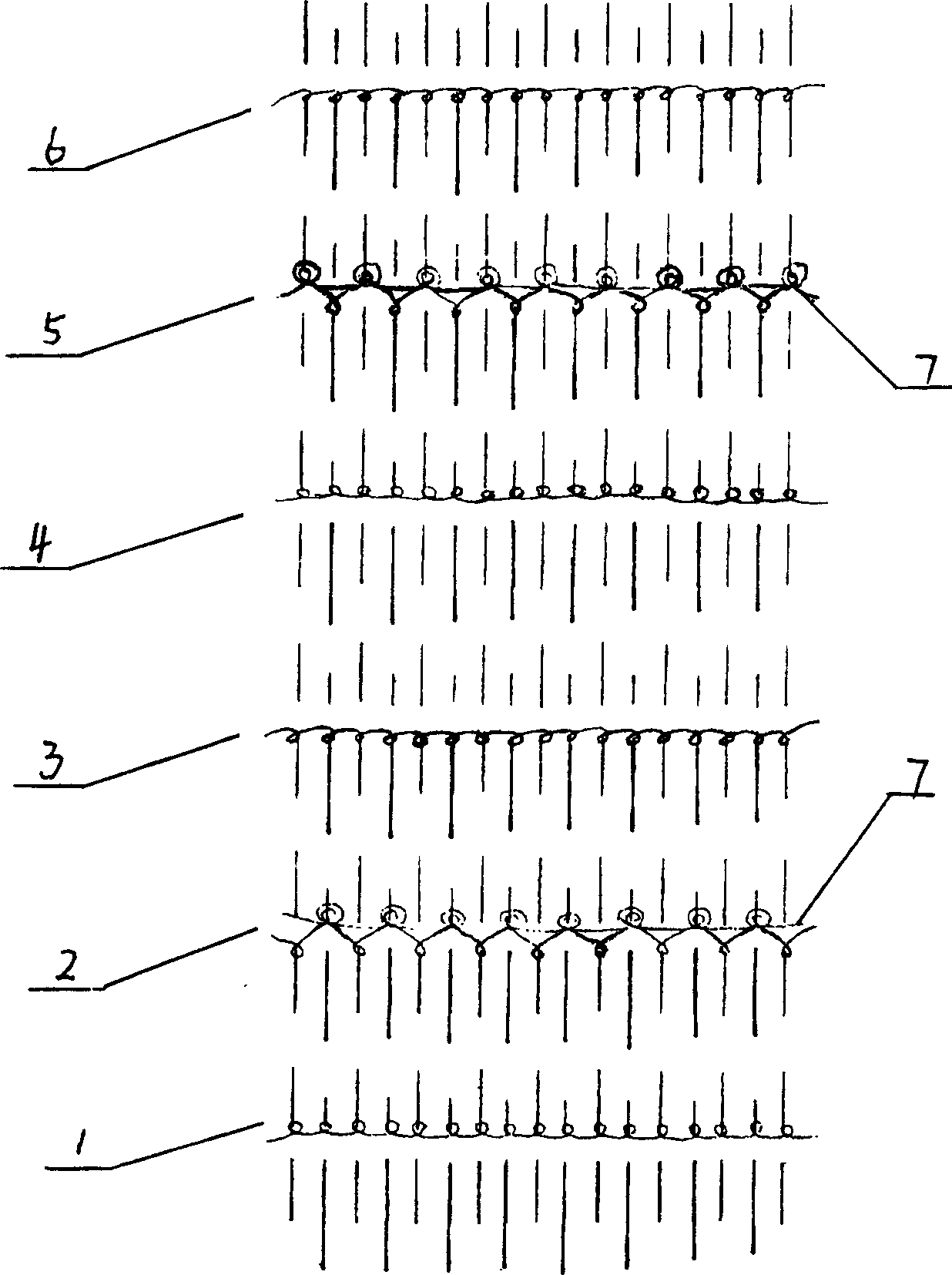

[0016] A double-sided knitted fabric with variable interlock weft and plain stitches and its knitting process is characterized in that the tissue unit of the double-sided knitted fabric is composed of two rib weaves and four single-jersey weaves, and the rib weaves are composed of color Spinning cotton yarn and DuPont Lycra fiber are interwoven. The single-sided weave is woven from colored spinning yarn. The DuPont Lycra fiber can be Lycra spandex bare silk 7, and the Lycra spandex bare silk can be selected from 3.3tex to 4.4tex. The color-spun cotton yarn can be selected from 14.6tex to 15.3tex, specifically, the Lycra spandex bare silk is selected as 4.4tex, and the color-spun cotton yarn is selected as 14.6tex.

[0017] The surface of this double knit fabric has checker-like sized loops for a tuck effect.

[0018] A weaving process for double-sided knitted fabrics with variable interlock weft and plain stitches, characterized in that the weaving process is composed of six y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com