Non negative pressure steady flow automatic water supply equipment

An automatic water supply, no negative pressure technology, applied in water supply devices, water saving, configuration of water supply pools, etc., can solve problems such as water pollution and energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

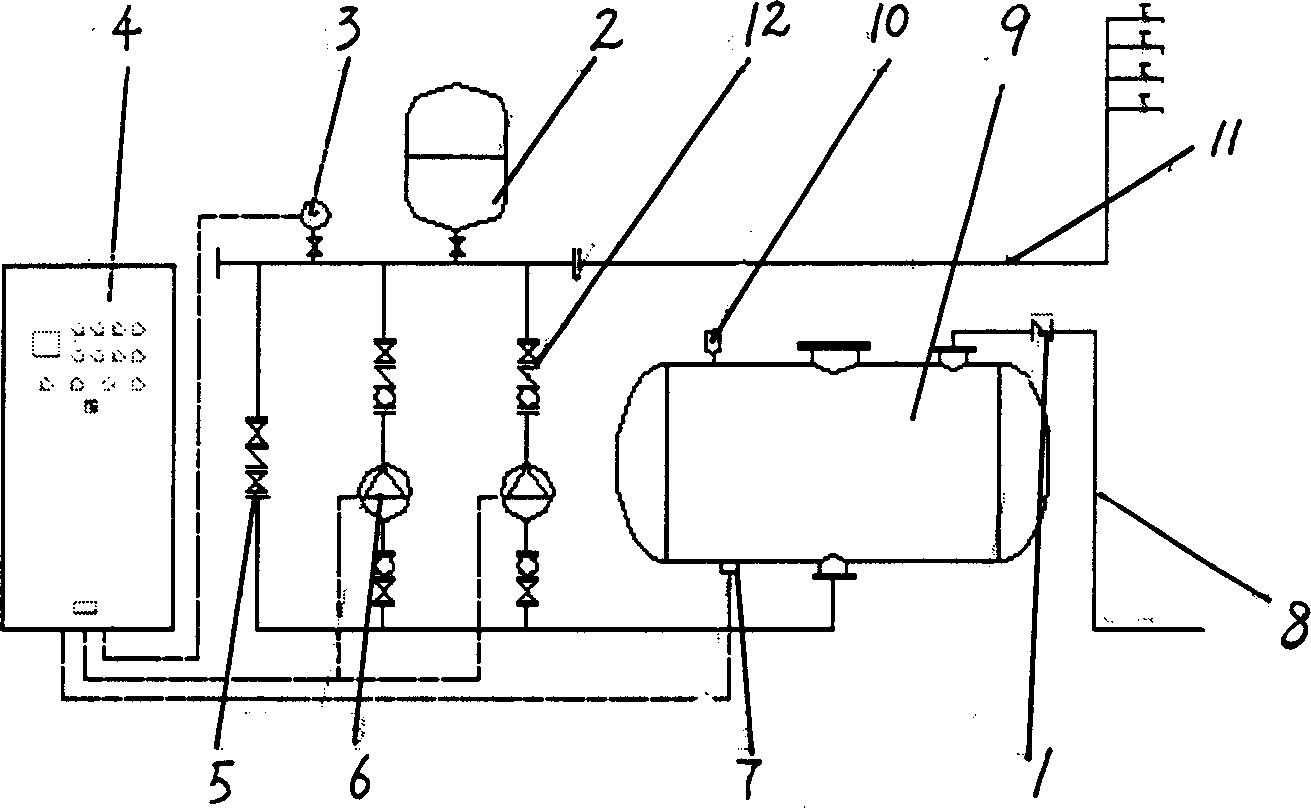

[0005] The figure includes a water inlet check valve 1, a pressure stabilizing tank 2, a pressure sensor 3, a frequency conversion cabinet 4, a control valve 5, a feed water pump 6, and a liquid level sensor 7. Tank 9, a vacuum eliminator 10 is connected to the steady flow tank 9, the outlet of the steady flow tank 9 is connected with two feed pumps 6 and a control valve 5, and an outlet pipe 11 is connected with three check valves 12, the check valves 12 are respectively connected to the outlet of the feed pump 6 and the outlet of the control valve 5, the outlet pipe 11 is connected with the surge tank 2 and the pressure sensor 3, the liquid level sensor 7, the pressure sensor 3, and the feed water pump 6 is connected to the frequency conversion cabinet 4. During use, the water of the tap water pipe network enters the steady flow tank 9 by the tap water inlet pipe 8, and the air in the tank 9 is discharged from the vacuum eliminator 10, and the vacuum eliminator 10 closes auto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com