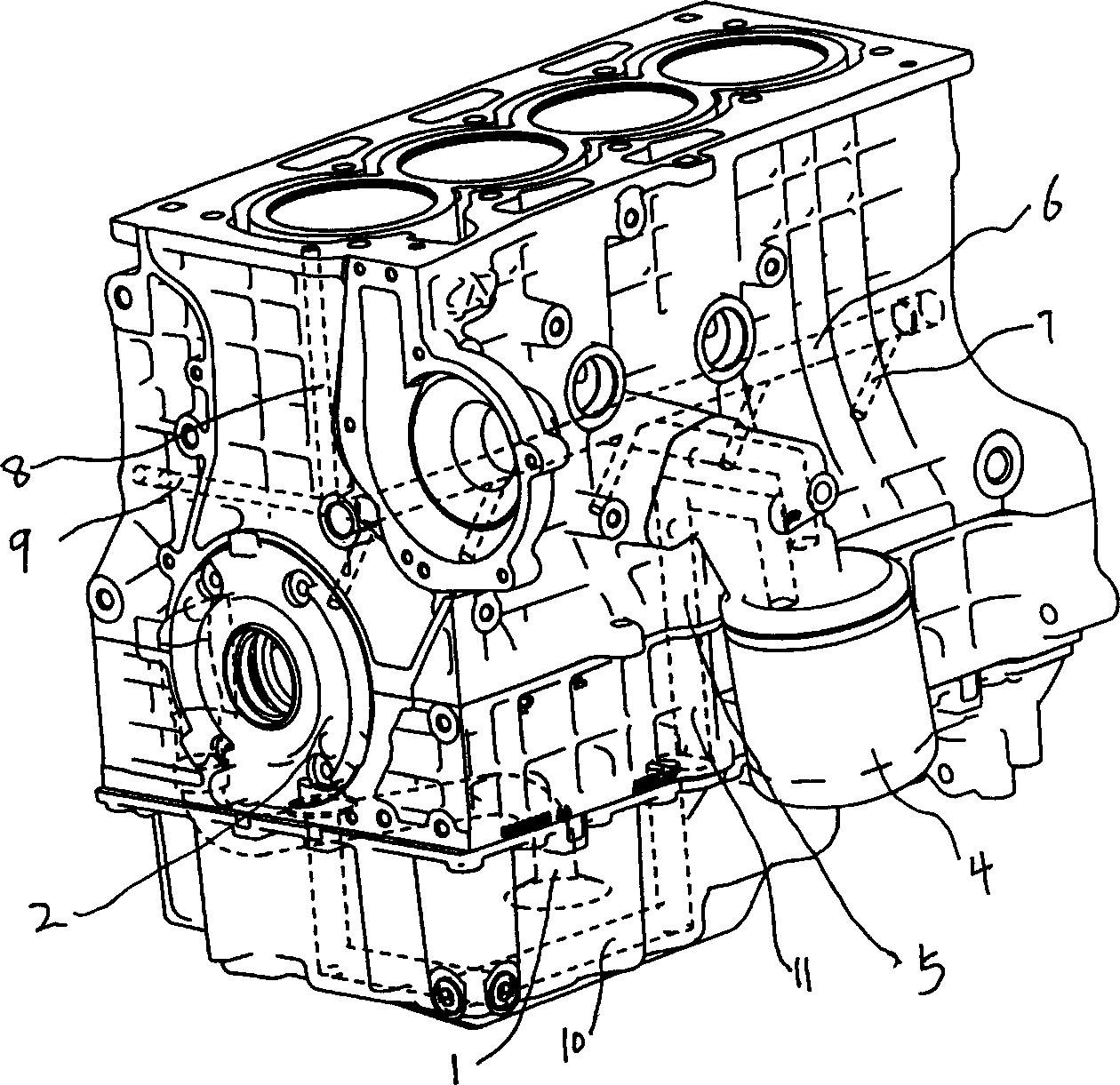

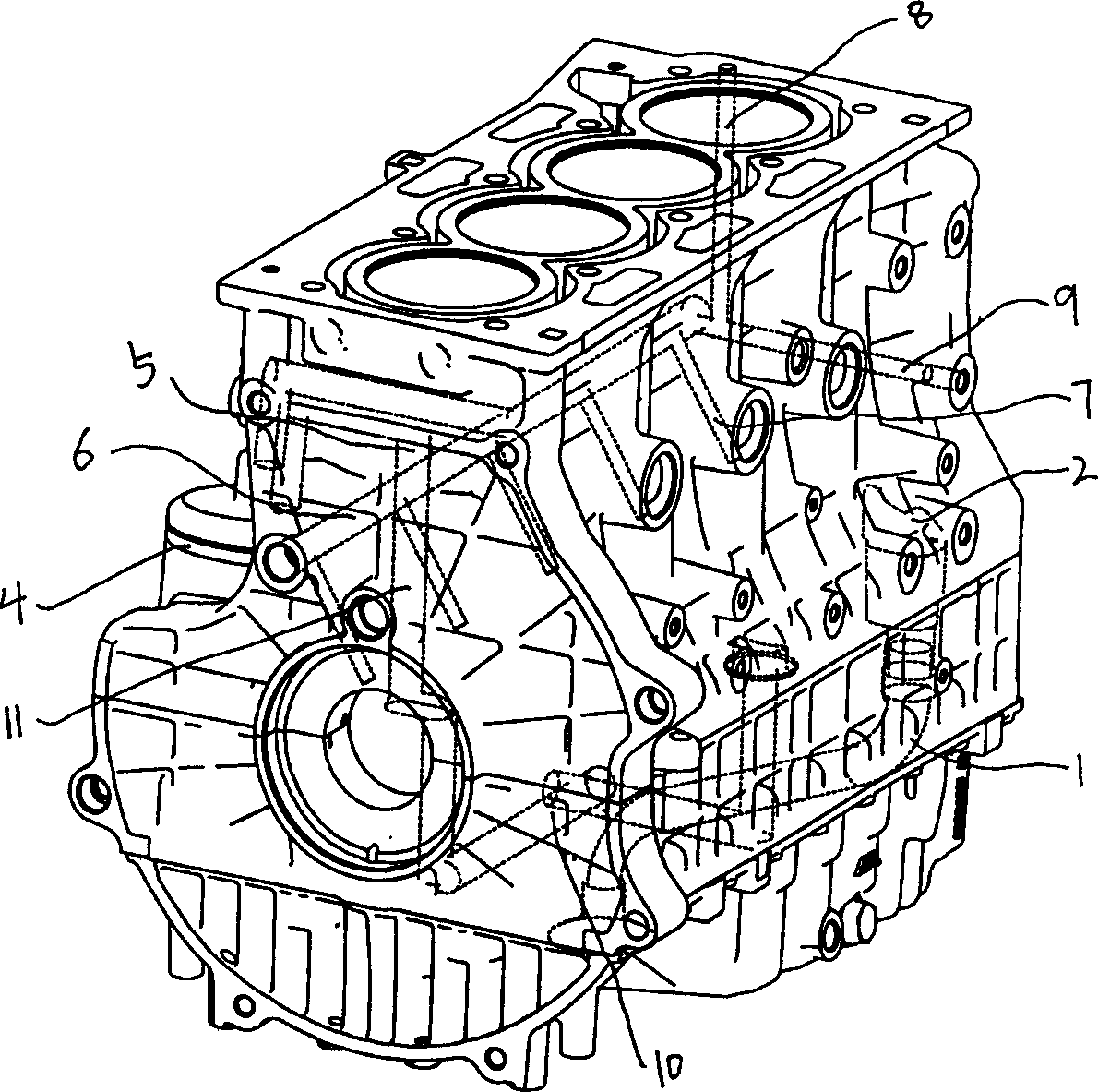

Lubricating oil-way of engine cylinder assembly

A technology of engine cylinder block and lubricating oil circuit, which is applied in the direction of pressure lubrication of engine components, machines/engines, and lubricating pumps. Beautiful design and enhanced overall rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Most of the oil pans of existing engines are stamped parts of thin steel plates. This process cannot realize the design of the lubricating oil circuit inside the oil pan. Because it is a thin-walled part, the vibration noise is relatively large. The lubricating oil path of the existing engine is as follows: oil collector assembly → oil pump assembly → external pipeline → oil filter → cylinder auxiliary oil passage → main oil passage → inclined oil passage and cylinder head vertical oil passage .

[0015] The role of the oil collector assembly is to absorb oil from the oil pan and perform primary filtration. The role of the oil pump assembly is to absorb and pressurize the oil, and there is an internal oil circuit connected to the oil collector and the external pipeline. The function of the external connection pipeline is to realize that the oil from the oil pump assembly enters the oil filter. The function of the oil filter is to filter the oil, and the filtered oil en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com