Electric fan with liquid bearing

A fan and rotating shaft technology, applied in the field of fans using fluid bearings, can solve the problems of high manufacturing cost and complicated fan structure, and achieve the effect of low manufacturing cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

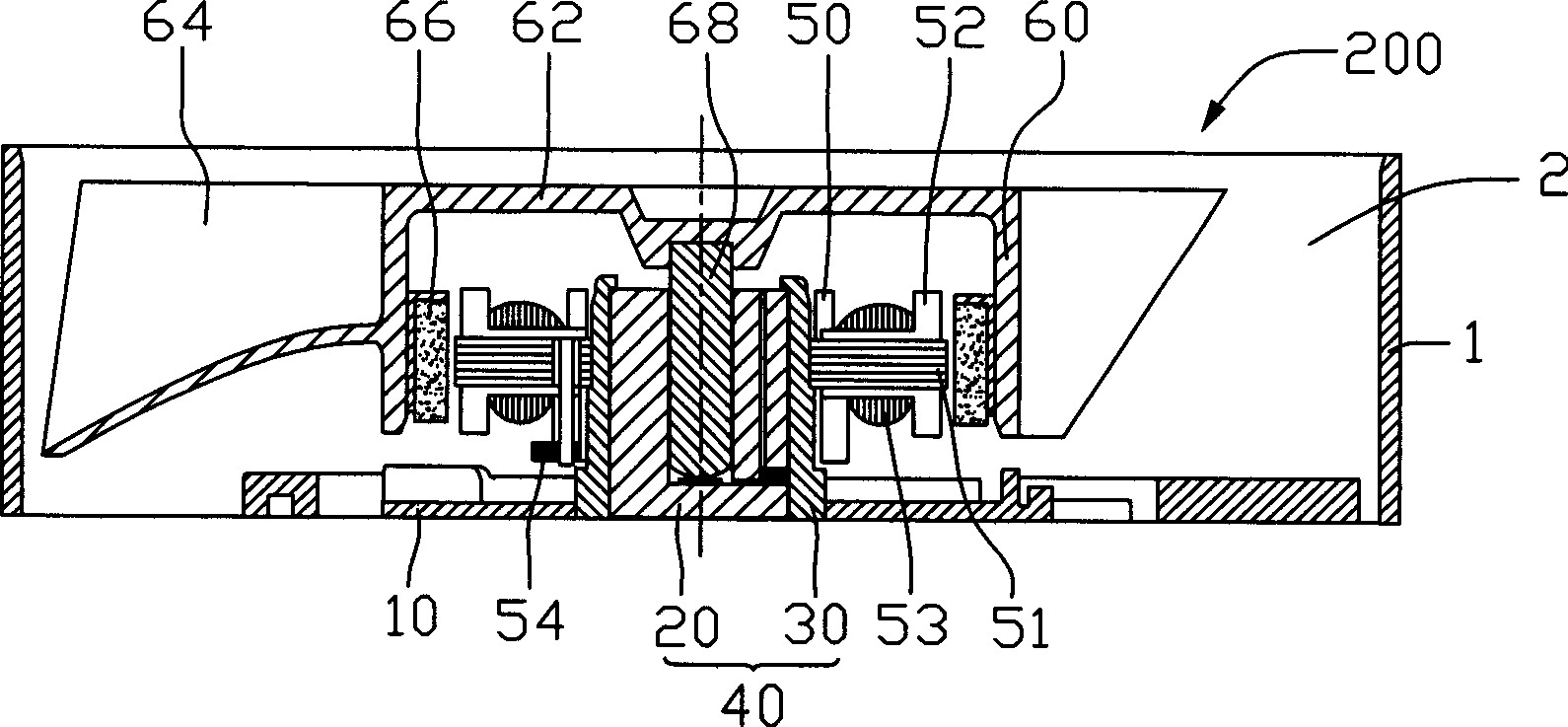

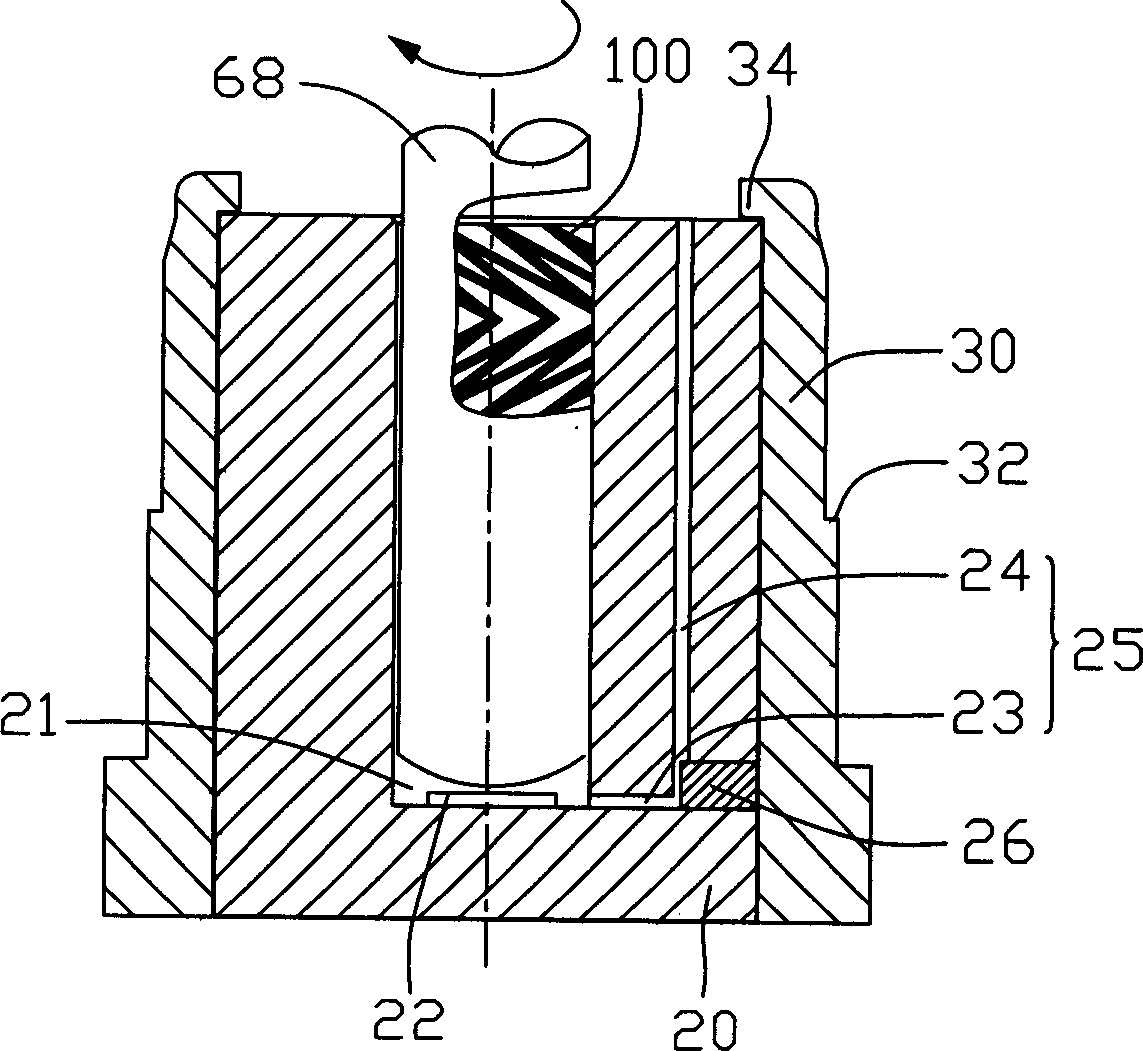

[0017] see figure 2 The fan 200 of the present invention includes a fan frame 1 with a cavity 2 in the middle, and a motor located in the cavity 2 . Wherein, the fan frame 1 is made of plastic material and includes a base 10 supporting other parts of the fan 200 . The motor includes a support 40 , a stator assembly 50 disposed around the support 40 , and a rotor assembly 60 rotatably supported on the support 40 . The supporting member 40 is disposed in the middle of the base 10 , and includes a shaft tube 30 disposed on the base 10 and a shaft sleeve 20 inside the shaft tube 30 .

[0018] The stator assembly 50 is disposed around the outer wall of the shaft tube 30 and includes a plurality of silicon steel sheets 51 , a pair of insulating frames 52 located at the upper and lower ends of the silicon steel sheets 51 , and a coil 53 wound on the insulating frames 52 . The coil 53 and the silicon steel sheet 51 are separated by an insulating frame 52 . The coil 53 is electrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com