Composite stainless steel rod with rainforced structure and its mfg. method

A technology of stainless steel strips and reinforcing structures, applied in the direction of slender elements, building elements, etc., can solve problems such as unsatisfactory effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

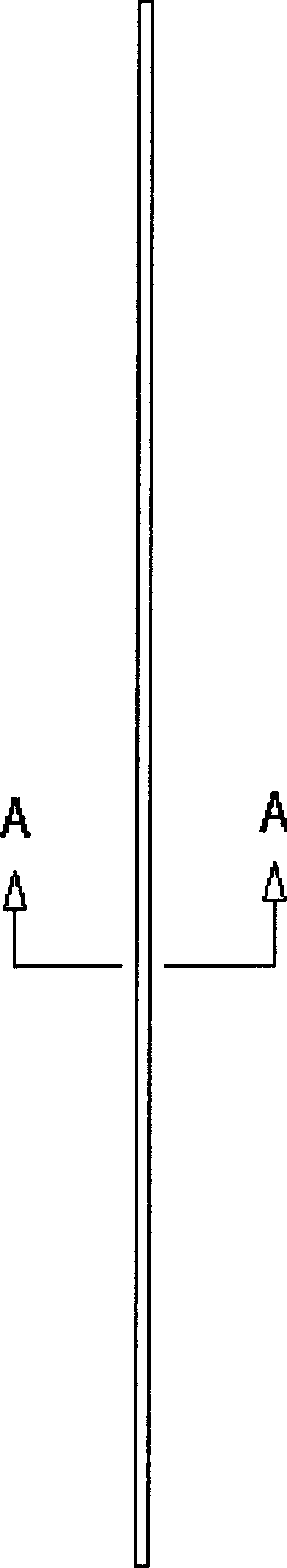

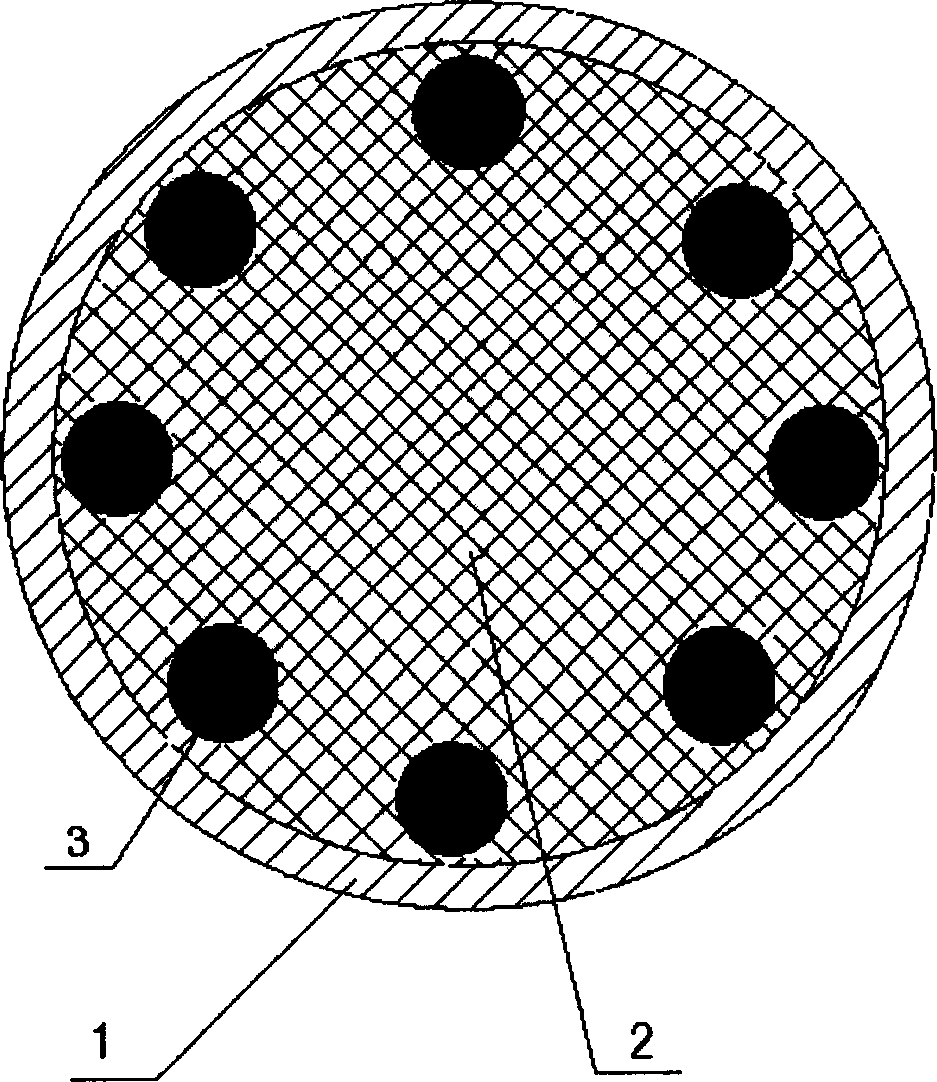

[0065] Specific embodiment 1, such as figure 1 , figure 2 shown along the figure 1 Schematic diagram of planing at A-A of the middle composite stainless steel bar, such as figure 2 As shown, the stainless steel pipe 1 is filled with artificial stone 2, the steel wire 3 is evenly placed along the inner wall of the stainless steel pipe 1, and the average distance between the steel wire 3 and the inner wall of the stainless steel pipe 1 is less than 3 mm.

specific Embodiment 2

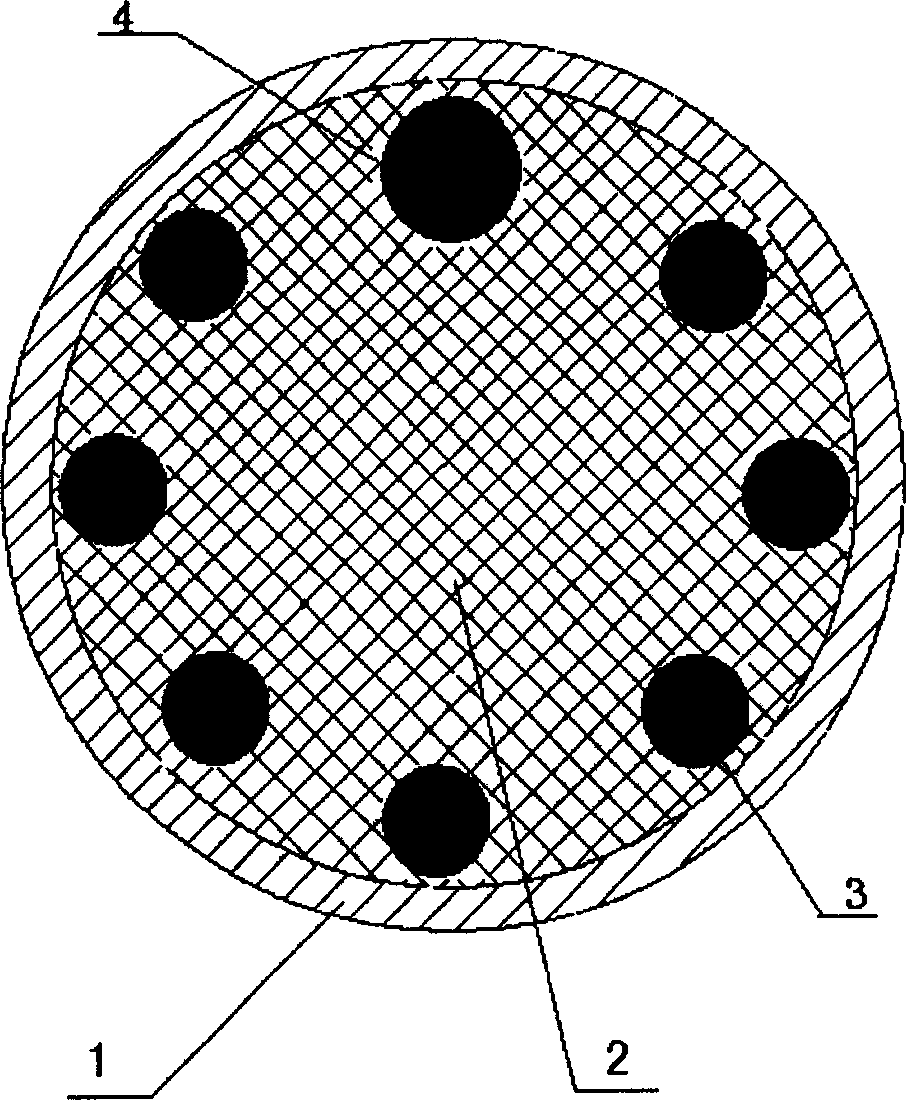

[0066] Specific embodiment 2, such as image 3 as shown, image 3 Among them, in the stainless steel pipe 1, there is a high-hardness steel wire 4 in addition to the steel wire 3. The high-hardness steel wire 4 is closely combined with the artificial stone, which can play a good anti-saw function and is not easy to be broken.

specific Embodiment 3

[0067] Specific embodiment 3, such as Figure 4 as shown, Figure 4 Among them, the filling is all high-hardness steel wire 4, and the outer surface of the high-hardness steel wire 4 is a rough surface, which is closely combined with the artificial stone.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com