Automobile steering system

A technology of automobile steering system and steering gear, which is applied in the direction of steering mechanism, steering rod, vehicle parts, etc., can solve problems such as tire abnormality, tire wear, and difficult coordination, and achieve weight reduction, interference resolution, and large adjustment space and range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

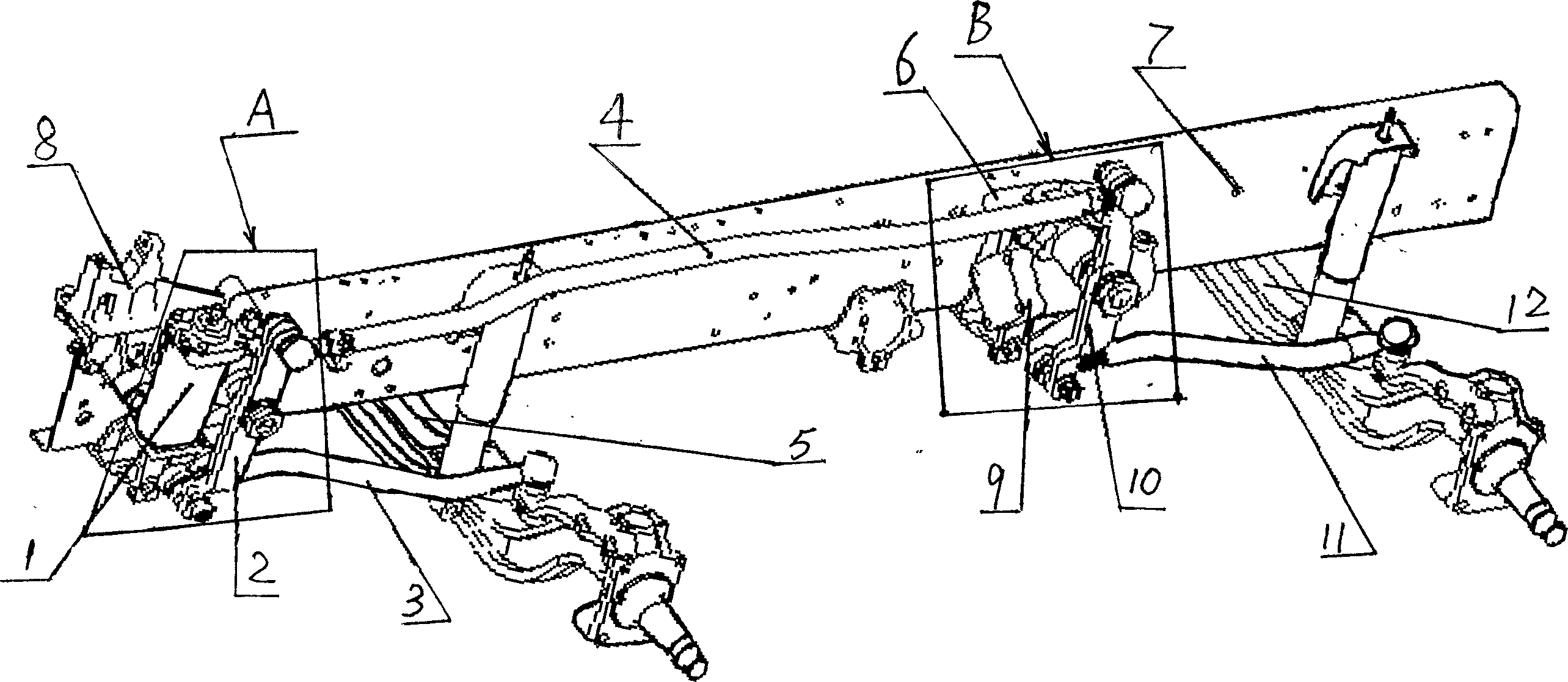

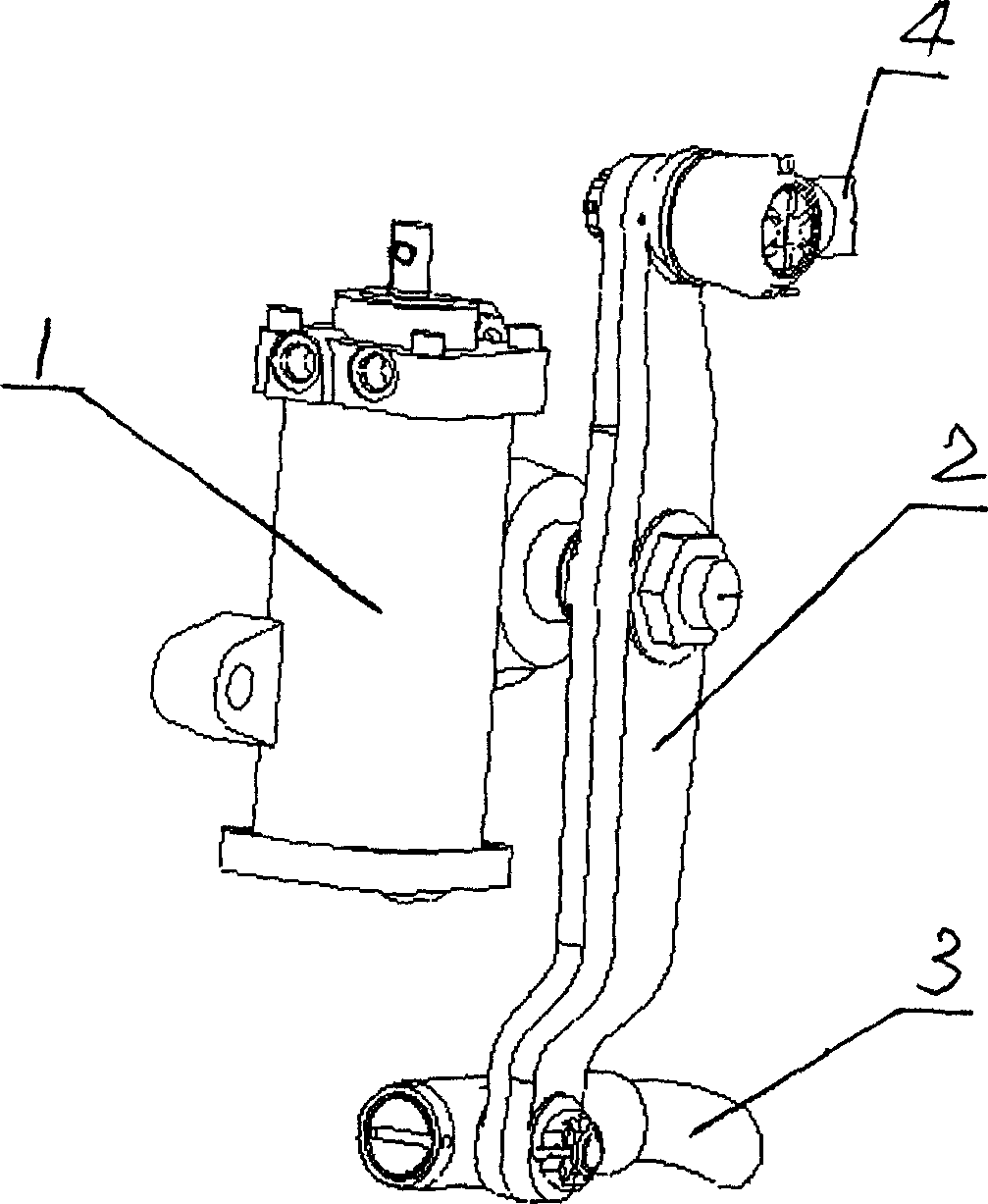

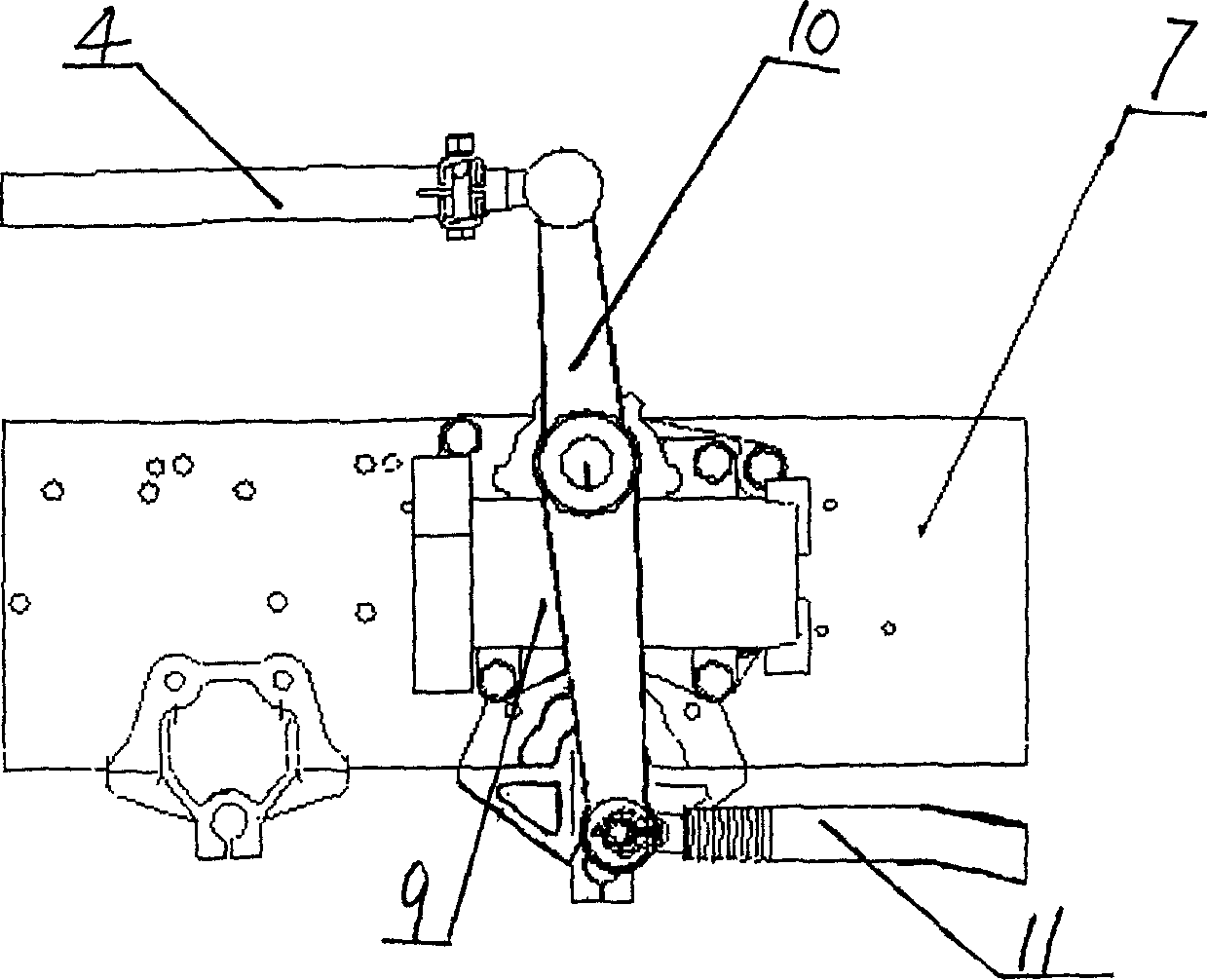

[0010] Such as figure 1 , 2 , 3, the steering gear 1 is fixed on the girder 7 through the steering gear bracket 8, the booster follower 9 is fastened on the girder 7 through the booster follower bracket 6, the middle part of the first drop arm 2 is connected with the steering gear 1 The output shaft is connected, the middle part of the second vertical arm 10 is connected with the output shaft of the booster follower 9, and the two ends of the connecting rod 4 are respectively hinged on the upper end of the first vertical arm 2 and the upper end of the second vertical arm 10. Hinged at the lower end of the first vertical arm 1 , the second bridge straight rod 11 is hinged at the lower end of the second vertical arm 10 . The straight tie rod 3 of the first axle is connected with the steering knuckle arm of the first front axle 5 , and the straight tie rod 11 of the second axle is connected with the steering knuckle arm of the second front axle 12 .

[0011] The length of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com