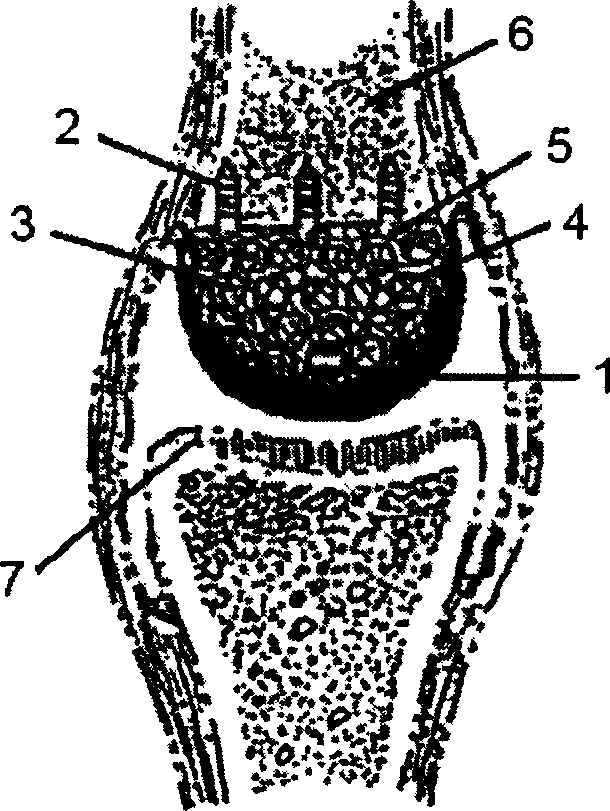

Compound artificial joint with artificial cartilage structure

An artificial joint and artificial technology, applied in the direction of joint implants, joint implants, prostheses, etc., can solve the problems of easy aging, no biological activity, aging and degeneration that cannot be maintained, and achieve a fixed and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0036] 2g chitosan powder is dissolved in the 3wt% chitosan solution that is formulated in the dilute acetic acid solution of 2wt% with concentration in 65ml, adds the guanidine hydrochloride solution (wherein BMP weight is 0.04g) of BMP and mixes homogeneously therein. Immerse the macroporous mechanical support unit structure of nano-hydroxyapatite / polyamide 6 with fixed rods and a pore size of 1 to 4 mm into the mixed solution, and in 10 -2 ~10 -1 Make the mixed solution completely fill the pores of the macroporous scaffold under 1 atmospheric pressure, take it out and freeze it at -10°C to -20°C for 24 hours, and then store it at 10 -4 ~10 -3 Freeze-dry for 24-36 hours at 1 atmospheric pressure. Then take it out and immerse it in 10wt% ammonia water for 2 to 6 hours, then wash it repeatedly with deionized water until the pH is about 7, and freeze it at -5°C for 24 hours, -4 ~10 -3 vacuum freeze-drying under 1 atmospheric pressure for 16-24 hours to obtain a composite po...

preparation example 2

[0039] Dissolve 2g of chitosan powder in 65ml of 3wt% chitosan solution prepared with 2wt% dilute acetic acid solution, add 10mg of TGF-β powder therein and stir evenly. Immerse the macroporous mechanical support unit structure of nano-hydroxyapatite / polyamide 66 with fixed rods and a pore size of 1 to 4 mm in the mixed solution, and in 10 -2 ~10 -1 Make the mixed solution completely fill the pores of the macroporous scaffold under 1 atmospheric pressure, take it out and freeze it at -10°C to -20°C for 24 hours, and then store it at 10 -4 ~10 -3 Freeze-dry for 24-36 hours at 1 atmospheric pressure. After taking it out, immerse it in 10wt% ammonia water for 2-6 hours, then wash it repeatedly with deionized water until the pH is about 7, freeze it at -5°C for 24 hours, and then freeze it at -5°C for 24 hours, -4 ~10 -3 vacuum freeze-drying under 1 atmospheric pressure for 16-24 hours to obtain a composite porous support unit.

[0040] Immerse the 1 / 4 length part of the othe...

preparation example 3

[0042] Dissolve 2g of chitosan powder in 65ml of 3wt% chitosan solution prepared with 2wt% dilute acetic acid solution, add 10mg of IGF powder therein and stir evenly. Immerse the macroporous mechanical support unit structure of nano-hydroxyapatite / polyamide 66 with fixed rods and a pore size of 1 to 4 mm in the mixed solution, and in 10 -2 ~10 -1 Make the mixed solution completely fill its pores under 1 atmospheric pressure, take it out and freeze it at -10°C to -20°C for 24 hours, and then store it at 10 -4 ~10 -3 Freeze-dry for 24-36 hours at 1 atmospheric pressure. After taking it out, immerse it in 10wt% ammonia water for 2-6 hours; then wash it repeatedly with deionized water until the pH is about 7, and freeze it at -5°C for 24 hours, and then freeze it at -5°C for 24 hours, -4 ~10 -3 vacuum freeze-drying under 1 atmospheric pressure for 16-24 hours to obtain a composite porous support unit.

[0043] Immerse the 1 / 4 length of the other end of the above-mentioned co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com