Nickle sheet positioning method

A positioning method and technology of nickel sheet, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of complex processing, poor flexibility, deformation of nickel sheet, etc., achieve simple process, easy sheet removal, avoid deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

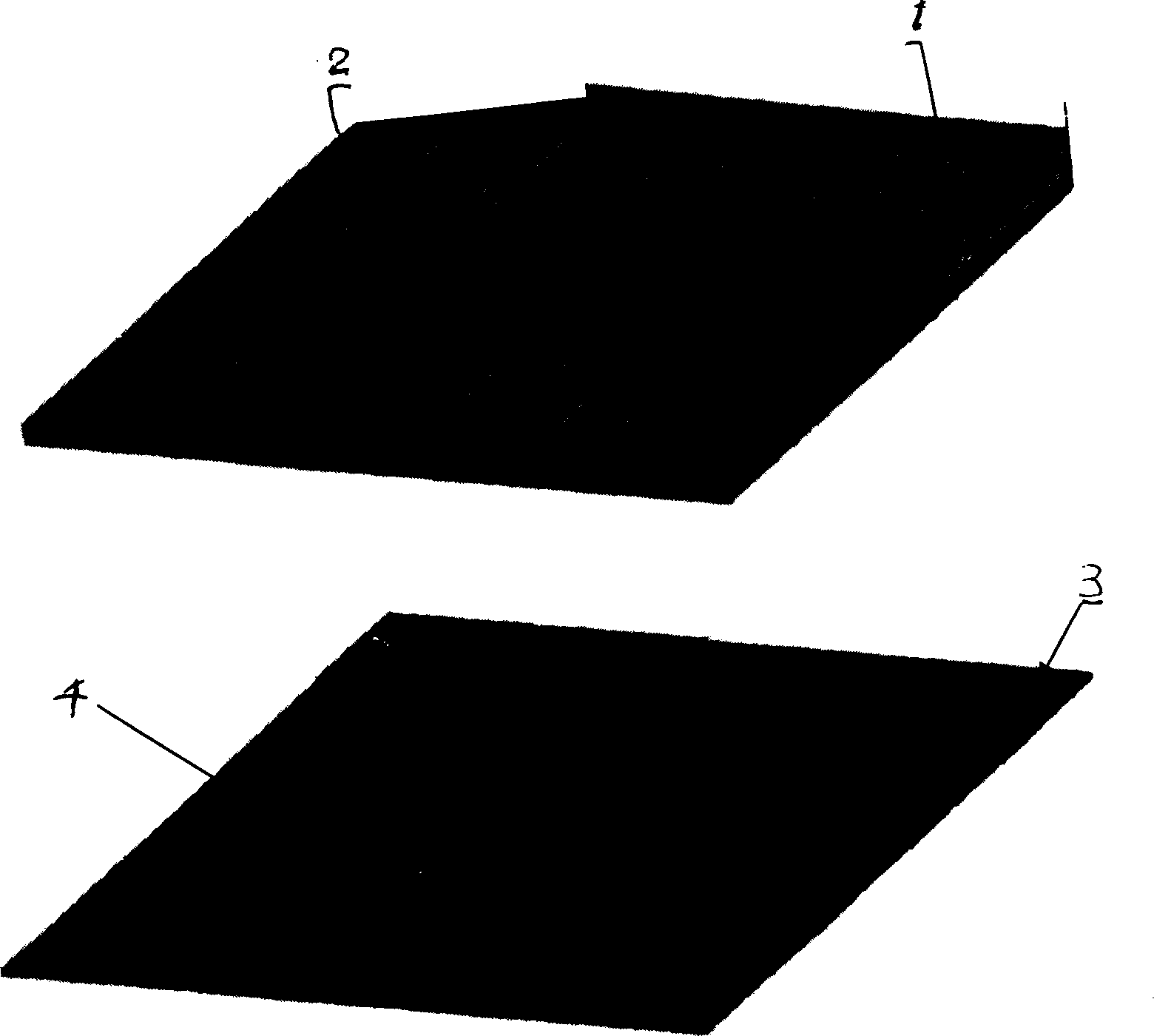

[0014] As shown in the structural exploded view of a novel nickel sheet positioning device of the present invention: a novel nickel sheet positioning device is composed of a nickel sheet positioning upper template 1 and a lower template 2, wherein the upper template 1 has a nickel sheet positioning groove 11 , The lower template 2 is provided with a magnet, and the upper and lower templates are positioned by positioning pins. In the embodiment of the present invention, the lower template 2 is all composed of magnets, and the magnets can also be fixed at places where nickel sheets are required to be positioned. The positioning is performed by positioning pins corresponding to the upper template. Its shape and size correspond to the positioning holes of the upper template. In this embodiment, a positioning hole 12 is provided on the upper template 1 to determine the position of the upper and lower templates, and a raised positioning column 21 is provided on the lower template 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com