Prification process

A purification method and hydrogen fluoride technology, applied in the direction of hydrogen fluoride, fluorine/hydrogen fluoride, etc., can solve the problems of loss of hydrogen fluoride, high-cost cooling methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

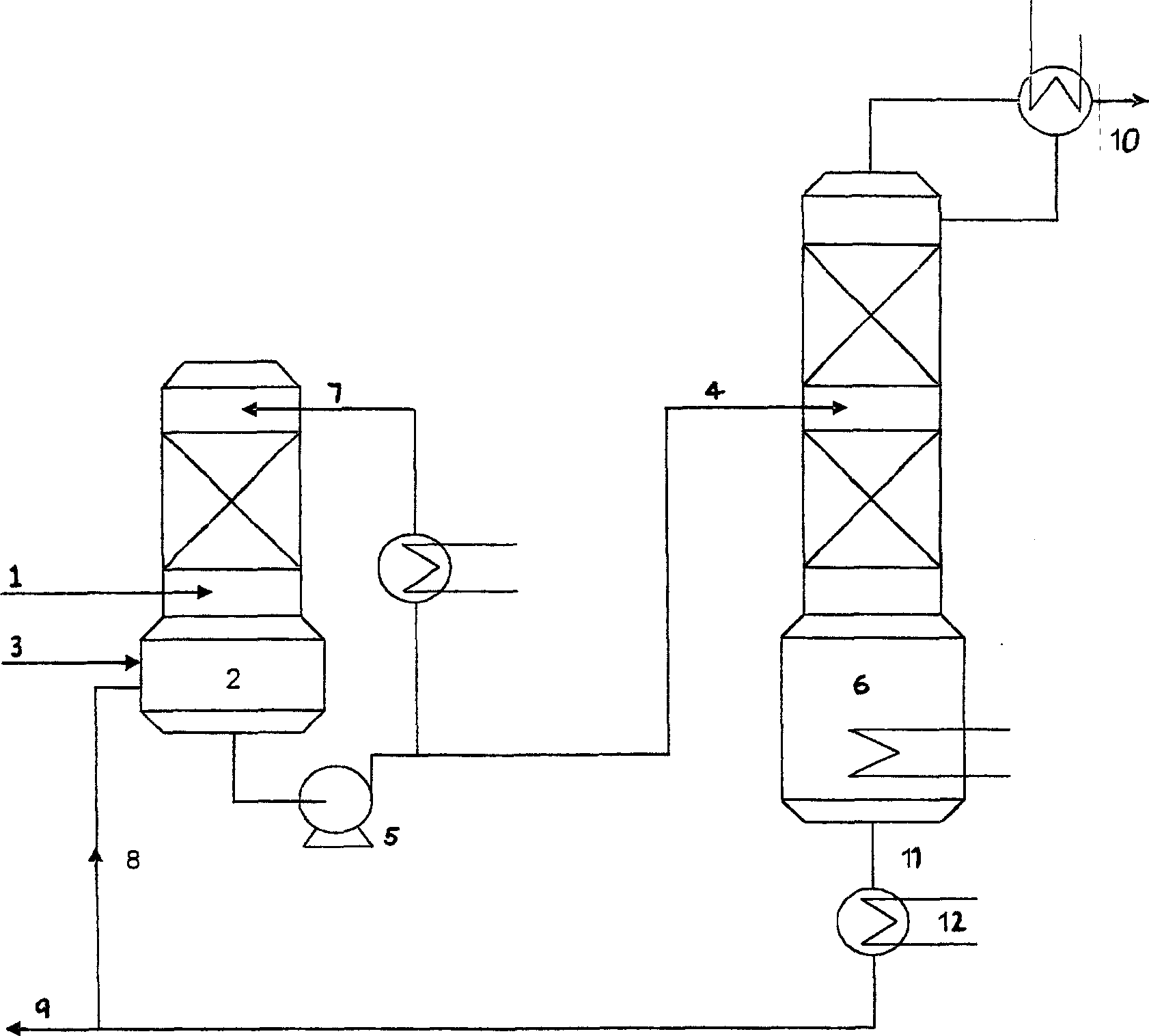

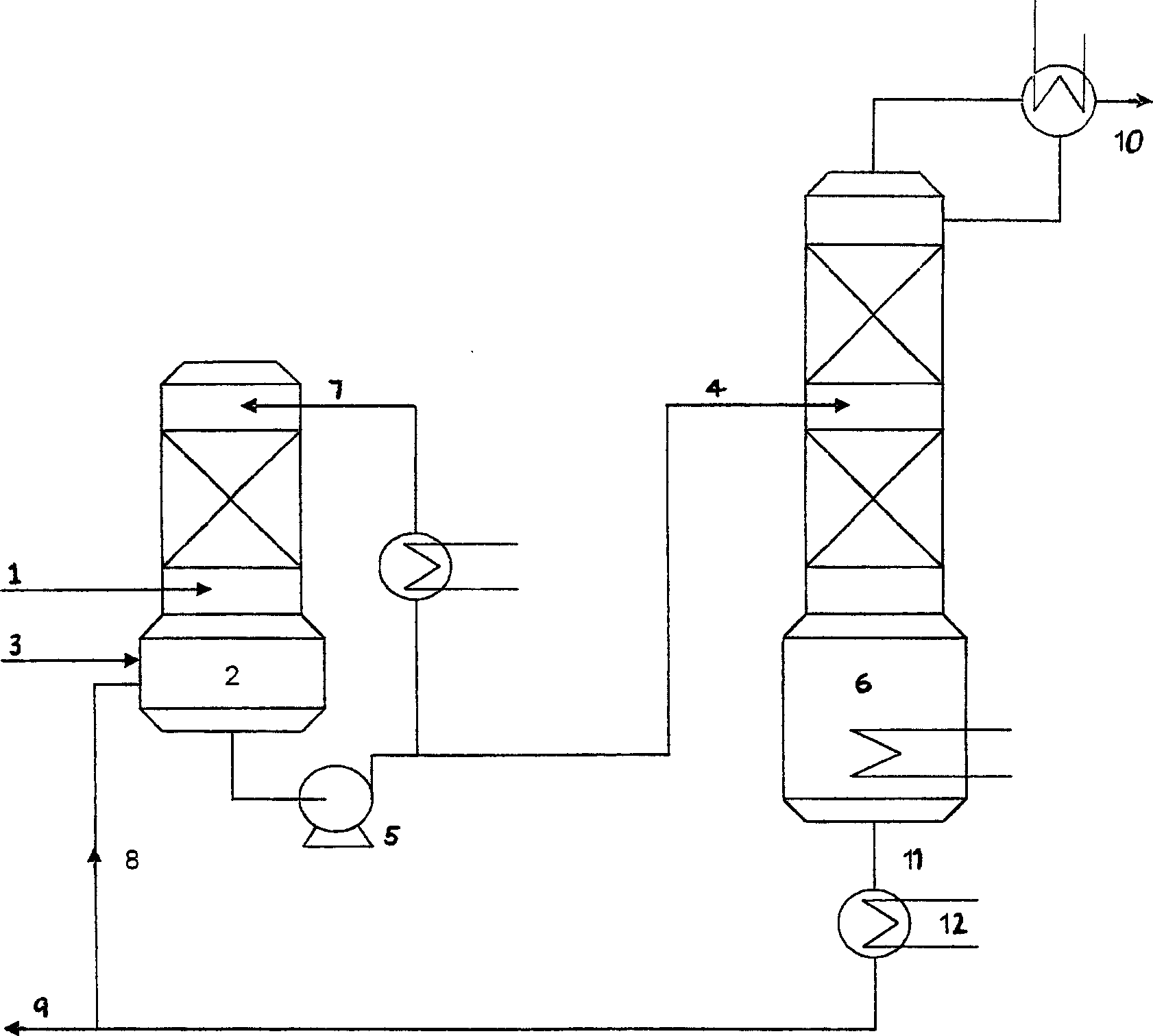

Method used

Image

Examples

Embodiment 1

[0038] With 0.5%P 2 O 5 The fluorspar and sulfuric acid are added to a converter together, and the hydrogen fluoride stream containing sulfuric acid, phosphorus and other impurities is obtained by the reaction. The gas stream was passed through a prepurifier to obtain a 2 SO 4 and 0.4%P 2 O 5 impure hydrogen fluoride stream. The impure gas stream was introduced into a packed column to contact a counter-flowing 45°C cooled aqueous hydrogen fluoride solution. Almost all gaseous components are cooled in this packed tower, and its liquid product contains 72% hydrogen fluoride, 25% water, 1% H 2 SO 4 and 2%P 2 O 5 . This stream was pumped into a distillation column with a working pressure of 3 bar. The operating temperature at the top of the distillation column was 65°C, the reflux rate was 2, and then hydrogen fluoride with a purity of 99.99% was obtained. The upper air stream contains only 0.01% water and less than 0.001% P 2 O 5 . The working temperature of the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com