Method of diagnosing pipeline welding crack using metal magnetic memory detecting signal

A technology of metal magnetic memory and welding cracks, applied in the direction of material magnetic variables, special data processing applications, instruments, etc., can solve the problems of limited promotion and application, distinction, etc., and achieve the effect of convenient on-line detection and fast non-destructive testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

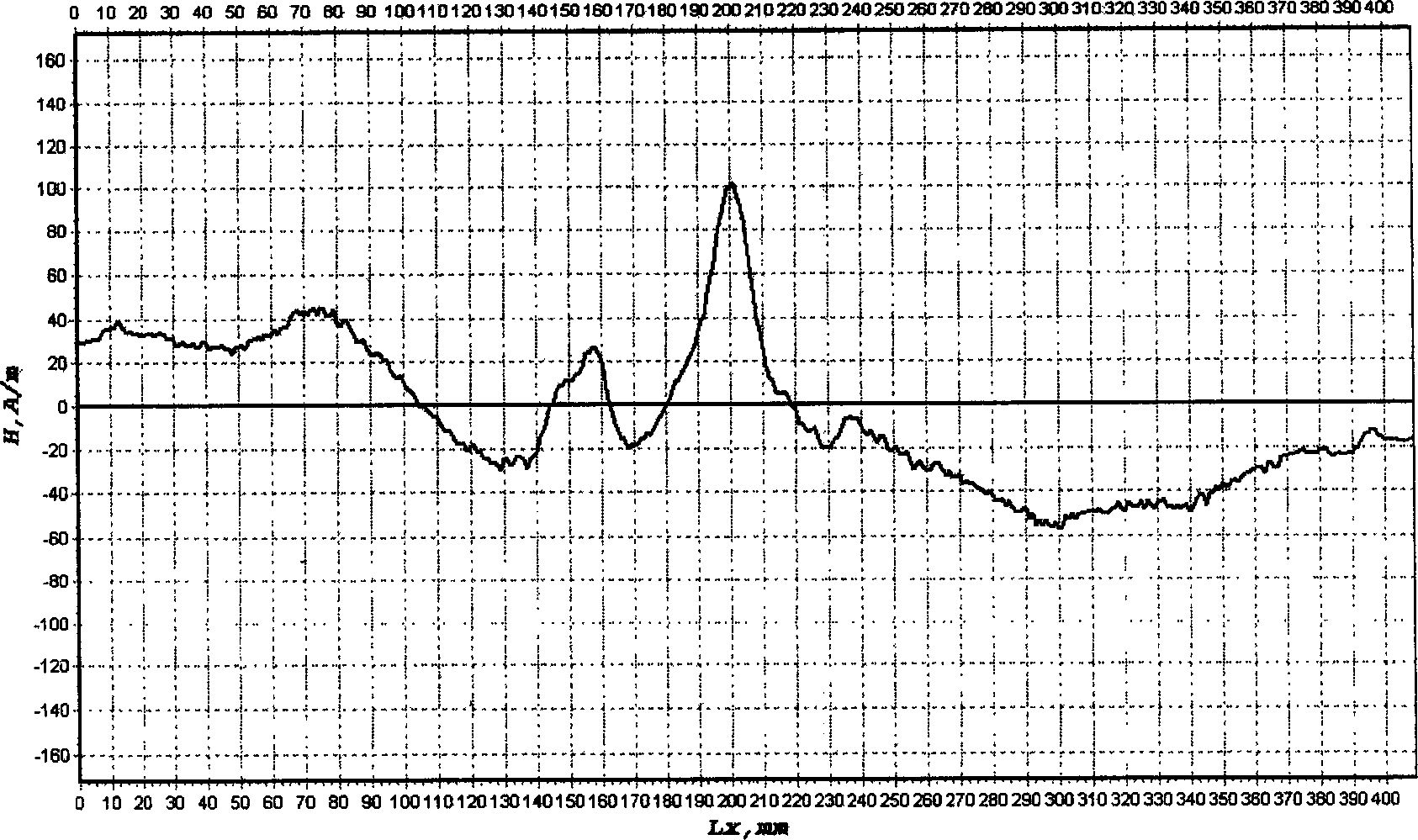

[0028] Use the TSC-1M-4 metal magnetic memory detector to detect the welded joint made of X70 pipeline steel. The geometric size of the steel pipe is Φ1016×21mm. The test results are as follows image 3 shown. Since the welding cracks have a certain length, in this example, the detection crack position accuracy is set to ±15mm, that is, the width of the window function is 30, so that it can be determined whether there is a welding crack within the detection range of 30mm. because K 0 It is related to the tensile strength of the tested material, for X70 pipeline steel, its tensile strength is σ b =656MPa, so K 0 The value is between 63.32 and 72.16. After the measured magnetic memory signal is processed in steps 1 to 4, the K values at the two positions 137mm and 241mm away from the starting position are 95.15 and 87.47 respectively, all satisfying K≥K 0 According to the judgment conditions, it can be judged that there are cracks in the two window parts 137mm and 241mm aw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com