Mechanical type tilting motion switch

A mechanical and switch technology, applied in the direction of electric switches, electrical components, circuits, etc., can solve the problems of high cost, unsuitable safety control of gas cookers, and difficult processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

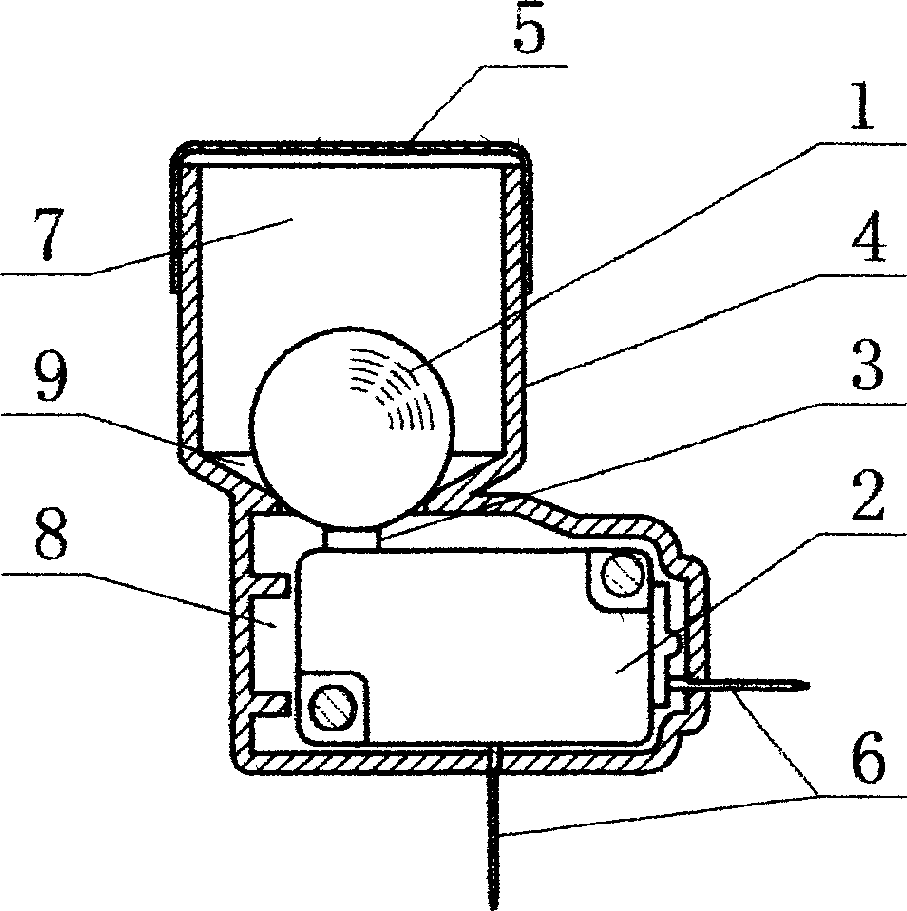

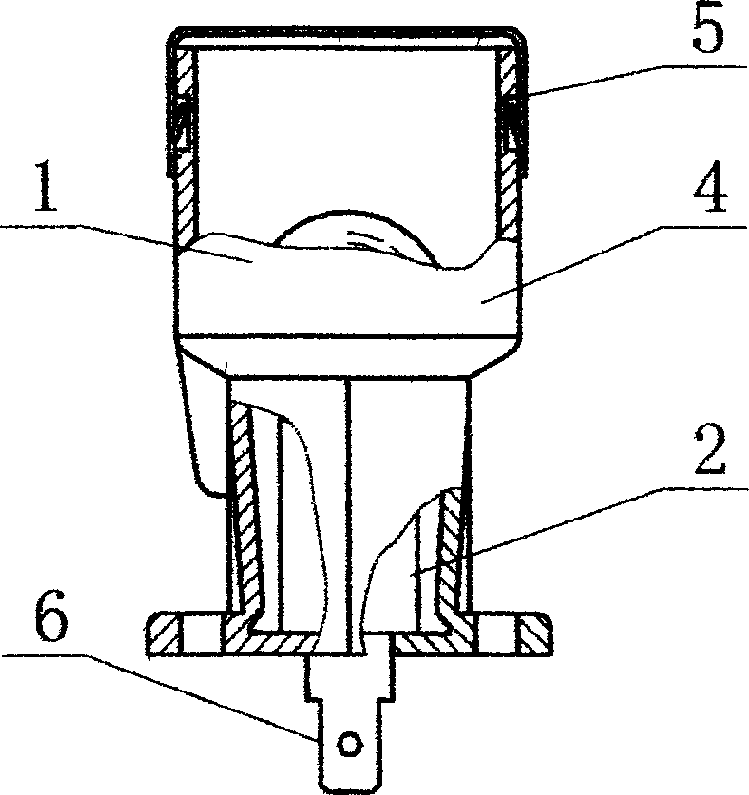

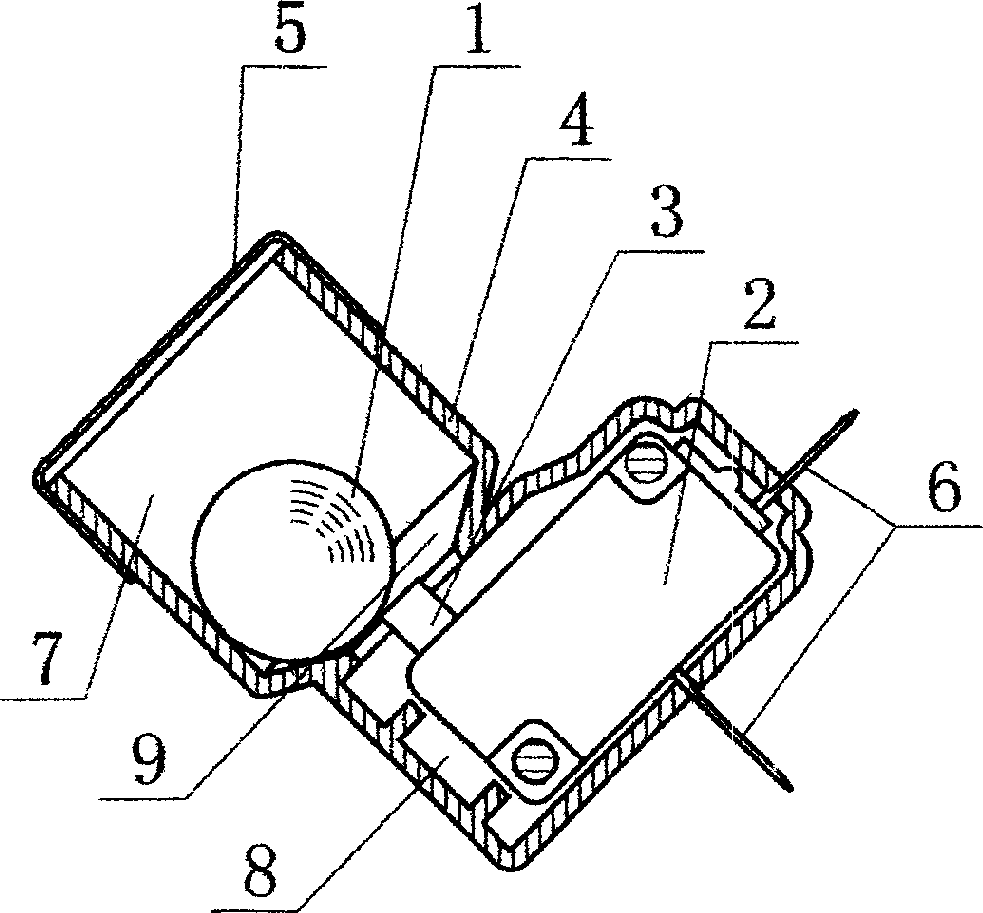

[0009] The following is a further detailed description of the mechanical dump switch in conjunction with the accompanying drawings:

[0010] The main function of the heavy ball 1 of the mechanical dump switch is to press the switch contact rod 3 of the micro switch 2 when the burner is vertical, and press it into the micro switch 2, and the micro switch 2 is in the power-on state. state, when the burner deviates from the vertical position and tilts, the heavy ball 1 will roll to the center position because the wall of the conical cavity 9 is an oblique cone, and the heavy ball 1 will be out of contact with the switch contact rod 3, and the switch contact rod 3 will pop out and reset , the micro switch 2 is in the electrical off state. Heavy Ball 1 uses steel balls.

[0011] The mechanical dump switch is equipped with a heavy ball 1 and a micro switch 2 in the housing 4 . The inner cavity of the housing 4 is divided into an upper cavity 7 , a conical cavity 9 and a lower cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com