Encapsulation structure for multiple chips

A multi-chip packaging and chip technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the mismatch of thermal expansion coefficient of packaging structure, affect the reliability of packaging structure, increase the overall thickness of packaging structure, packaging process and material cost, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

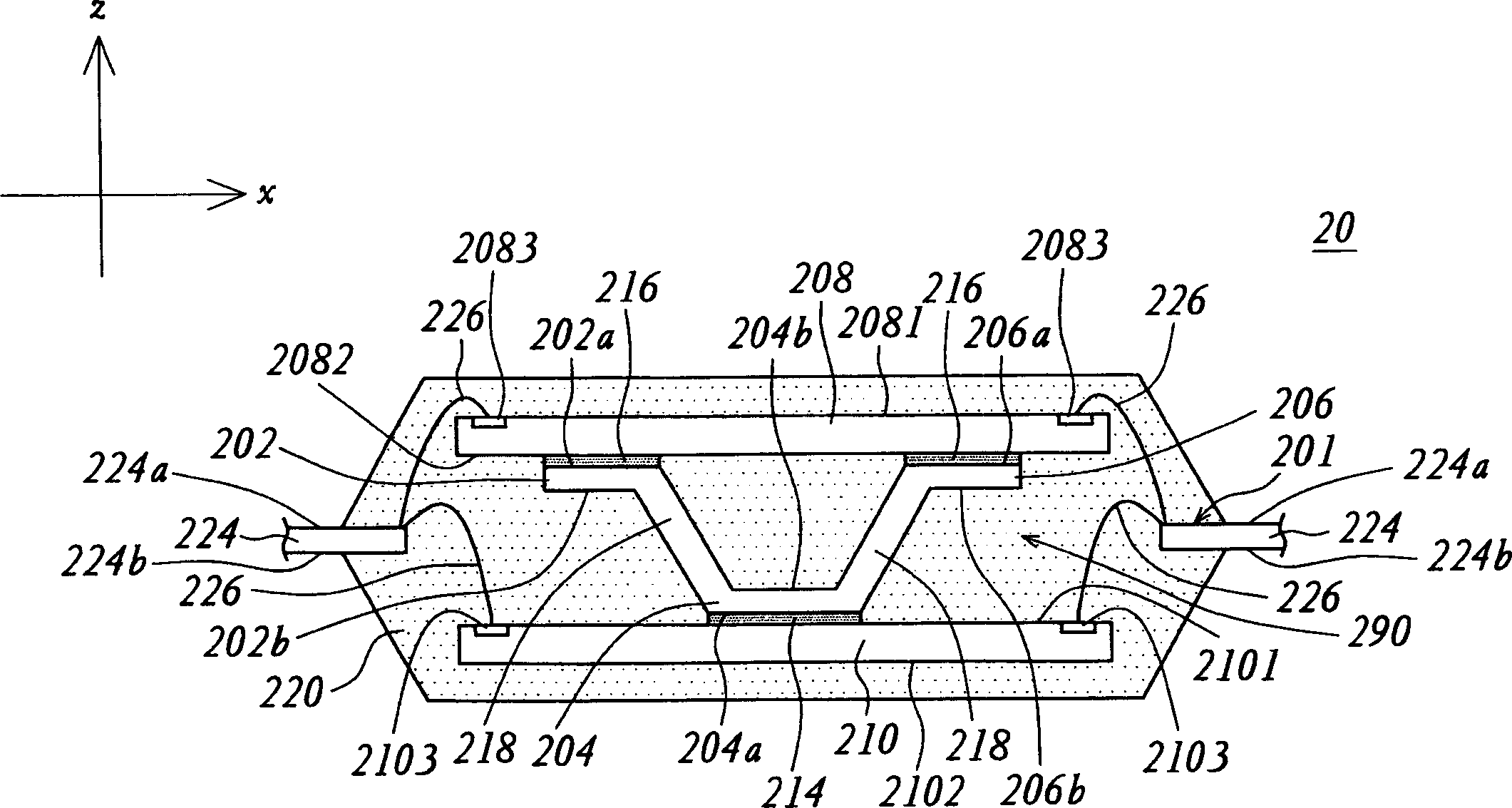

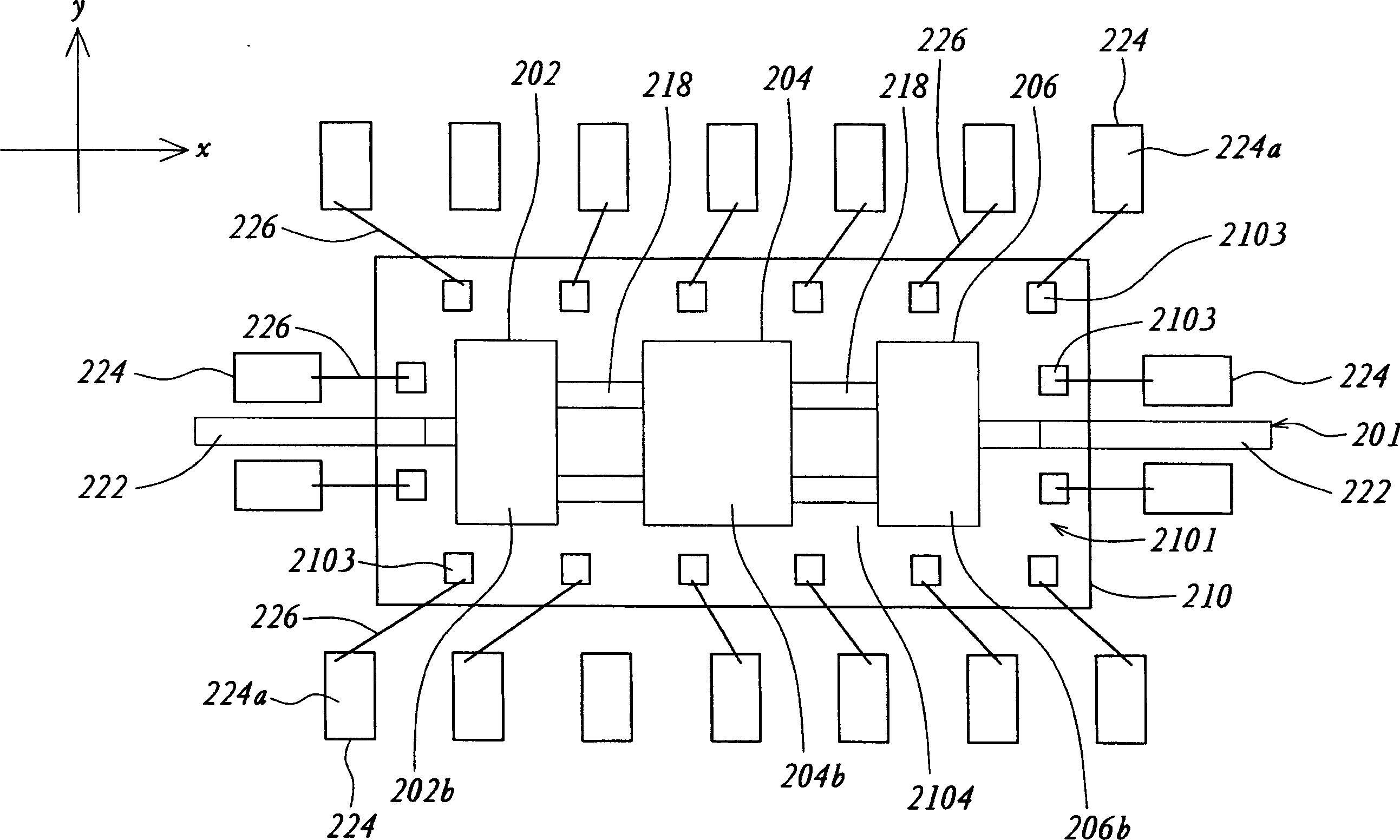

[0045] Please refer to figure 2 , which shows a cross-sectional view of the multi-chip packaging structure according to Embodiment 1 of the present invention. exist figure 2 Among them, the multi-chip package structure 20 includes a lead frame 201 , two chips 208 and 210 with the same or similar size, several wires 226 and an encapsulant 220 . In order to allow the active surfaces of chips 208 and 210 with similar or identical dimensions to face the same direction, the lead frame 201 is specially designed in this embodiment. The chip pad connection structure 218 connecting the first chip pad and the second chip pad and several inner pins 224 surrounding the periphery of the first chip pad and the second chip pad.

[0046] The first chip mount has a first die-bonding surface and a first non-die-bonding face opposite to each other, the second die mount has a second die-bonding face and a second non-die-bonding face opposite, and the die mount connection structure 218 is conn...

Embodiment 2

[0052] Please refer to Figure 4 , which shows a cross-sectional view of the multi-chip packaging structure according to Embodiment 2 of the present invention. The difference between the multi-chip packaging structure 20a of this embodiment and the multi-chip packaging structure 20 of Embodiment 1 is that the multi-chip packaging structure 20a of this embodiment further includes a chip 250, several wires 226a and an encapsulating body 220a, the chip The size of 250 is smaller than the size of chips 208 and 210 . As for the other components of the multi-chip packaging structure 20a of the present embodiment that are the same as those of the multi-chip packaging structure 20 of the first embodiment, the same reference numbers are used, and the connection relationship between them will not be repeated here.

[0053] The chip 250 has an active surface 250 a and a non-active surface 250 b opposite to each other, and the active surface 250 a has several bonding pads 2503 . The non...

Embodiment 3

[0055] Please refer to Figure 5 , which shows a cross-sectional view of a multi-chip packaging structure according to Embodiment 3 of the present invention. exist Figure 5 Among them, the multi-chip package structure 30 includes a lead frame 301 , two chips 308 and 310 with the same or similar size, several wires 326 and an encapsulant 320 . In order to allow the active surfaces of the chips 308 and 310 with similar or identical dimensions to face the same direction, the lead frame 301 is specially designed in this embodiment. The lead frame 301 has a first chip seat and a second crystal seat with height differences, several The chip pad connecting structure 318 and several inner pins 324 are used to connect the first chip pad and the second chip pad.

[0056] The first chip holder has a first bonding surface and a first non-sticking surface, the second chip holder has a second bonding surface and a second non-sticking surface, and the chip holder connection structure 318 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com