Pulsating stepless transmission

A technology of continuously variable transmission and rotary motion, applied in the direction of transmission, gear transmission, belt/chain/gear, etc., can solve the problem of large pulsation, complex structure of pulsating continuously variable transmission, load capacity of one-way overrunning clutch and impact resistance Capability limitations and other issues, to achieve stable performance, improved reliability, stable and accurate output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

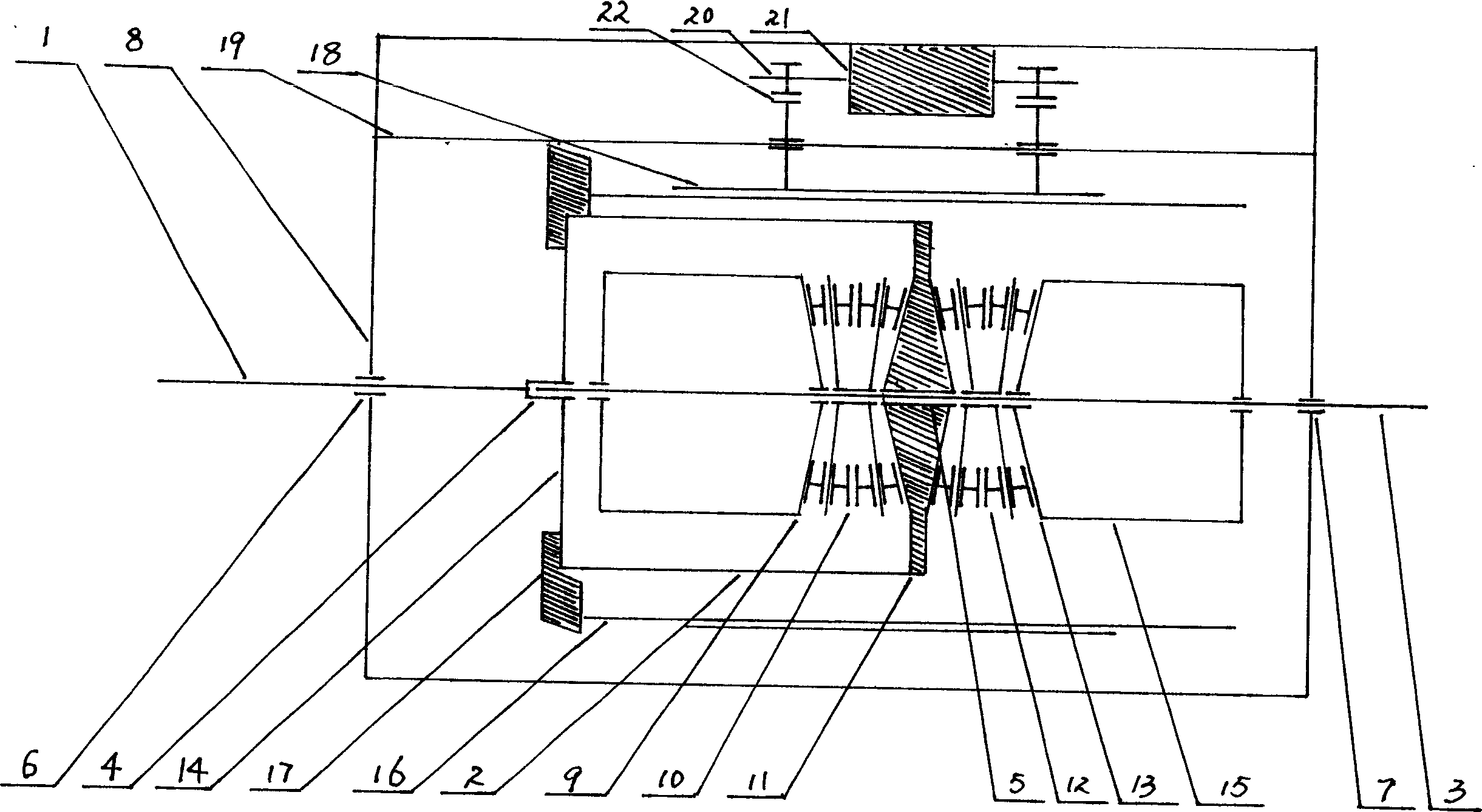

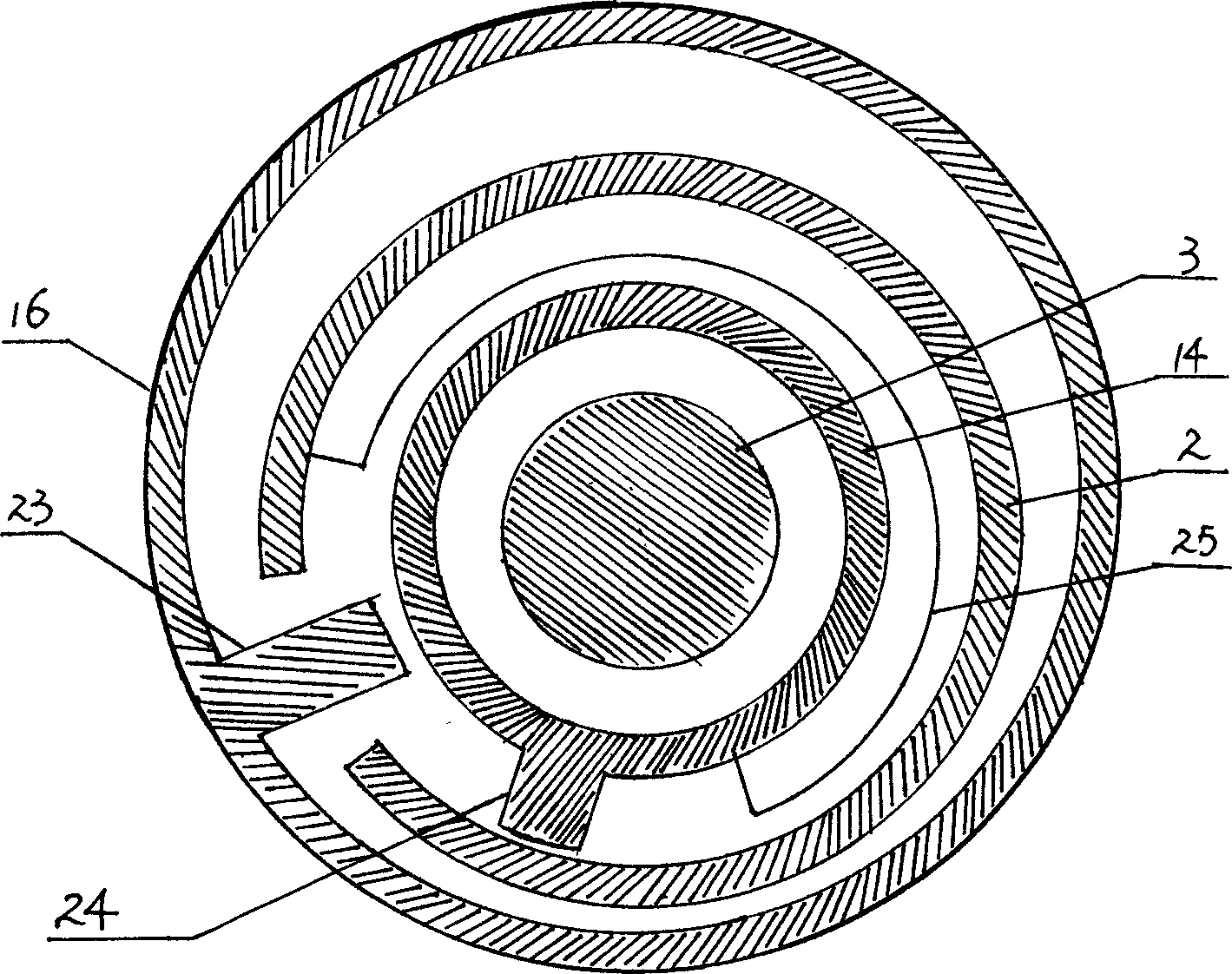

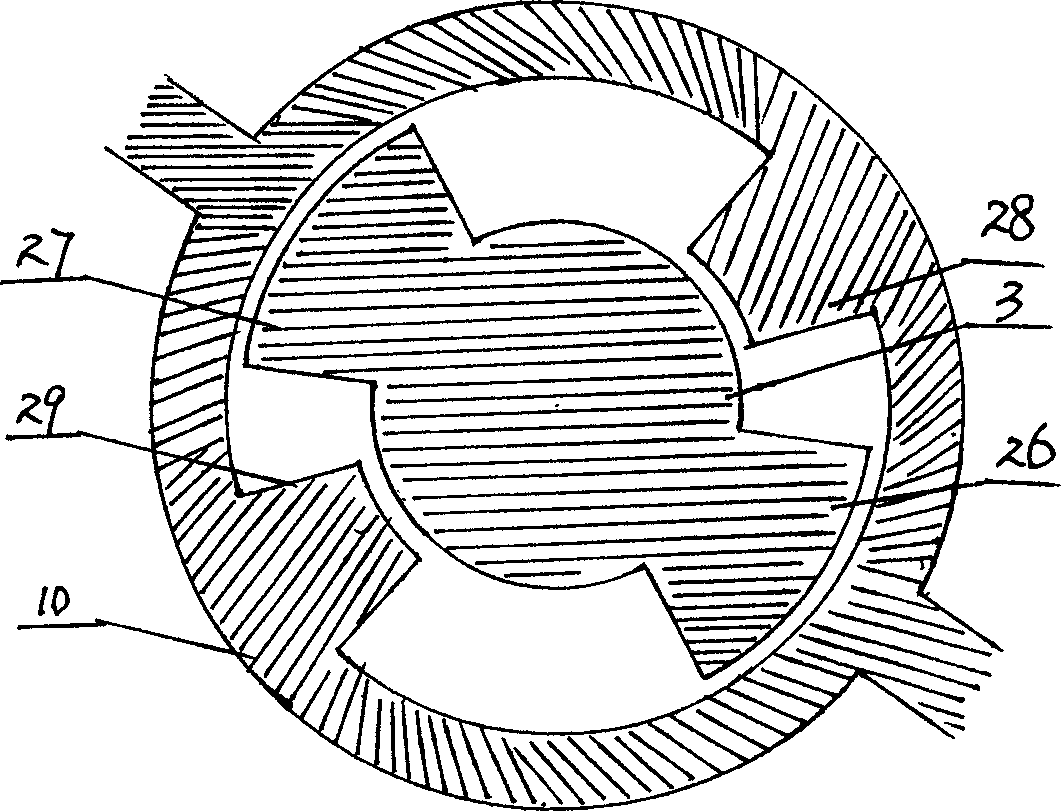

[0014] figure 1 The schematic diagram of the pulsating continuously variable transmission provided by the present invention is shown. The input shaft (1) of the pulsating continuously variable transmission and the input shaft cylinder (2) integrated with the input shaft and the output shaft (3) are concentric with each other and can pass through The bearing (4) and the bearing (5) support each other, the input shaft is supported on the housing (8) through the bearing (6), and the output shaft is supported on the housing (8) through the bearing (7). (9), (11) are the two conical center wheels of the 2Z-X type positive sign mechanism bevel gear differential train with a transmission ratio of 1:1, (10) are the rotating arms of the differential train, two conical Center wheel (11), (13) and rotating arm (12) constitute another bevel gear differential train. The two bevel gear differential trains share a center wheel (11), and the center wheel (11) is integrated with the input sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com