Lamp feeding system and lamp thereof

一种馈电系统、馈电线的技术,应用在馈电系统领域,能够解决灯减少使用寿命、断落、环境加重负担等问题,达到热力负荷减小的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

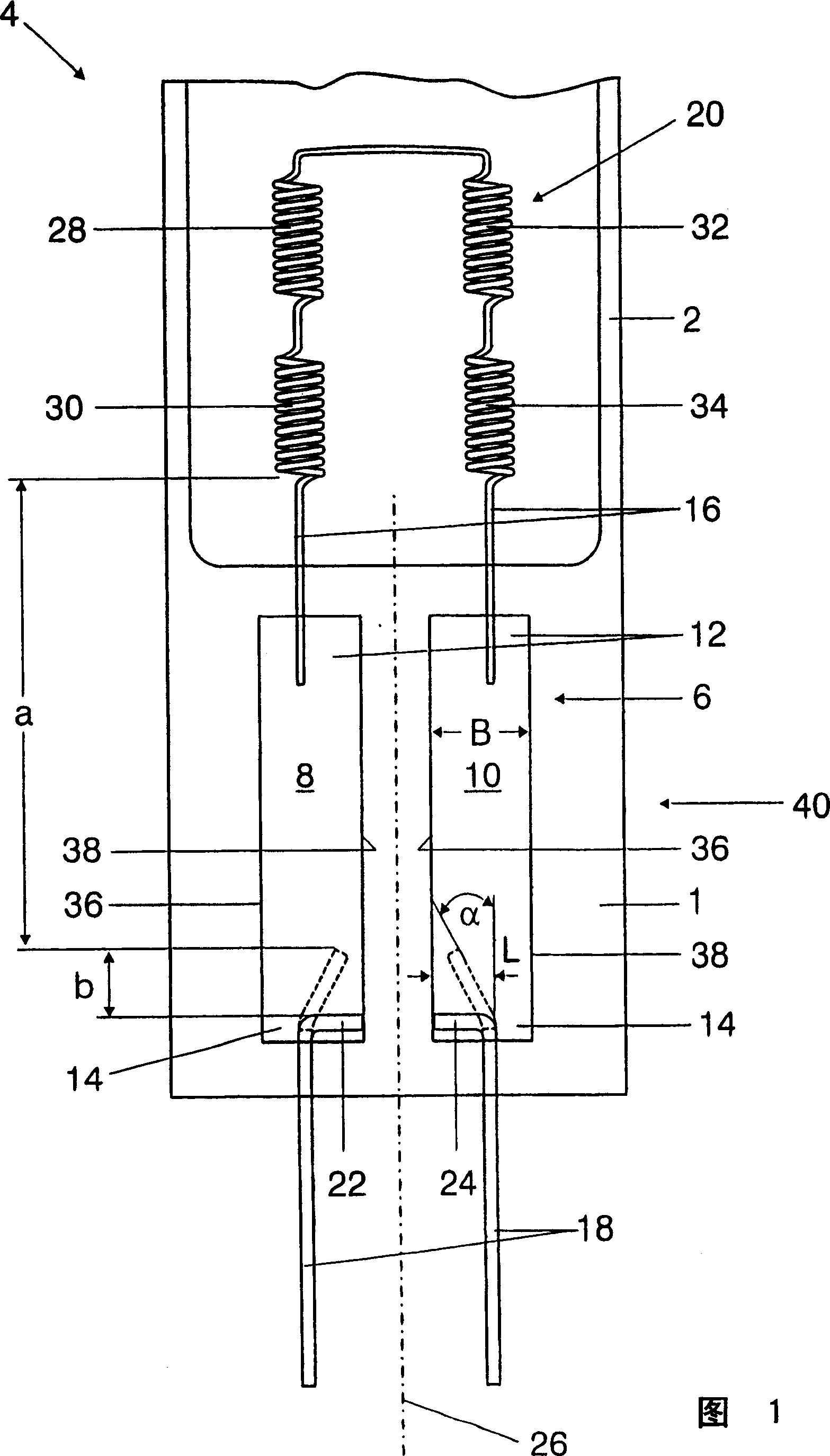

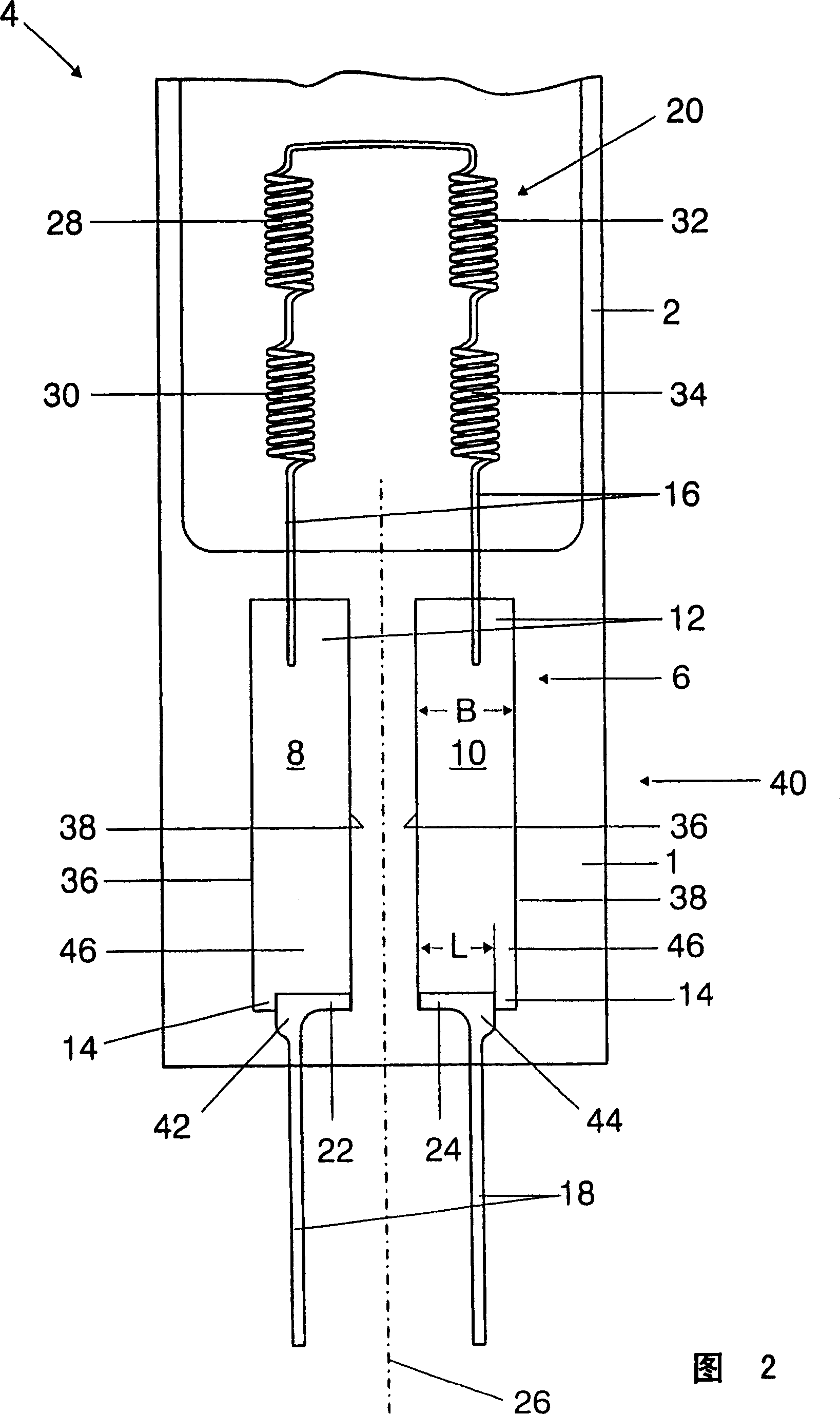

[0020] FIG. 1 shows the closing seal 1 of a lamp envelope 2 made of quartz glass for an electric lamp 4 which has a power supply system 6 according to the invention.

[0021] The feed system 6 has two approximately rectangular molybdenum foils 8 , 10 which are embedded airtight in the end seal 1 of the lamp 4 , wherein an inner feeder is respectively arranged on two opposite narrow sides 12 , 14 . The electrical line 16 and an outer power supply line 18 are used for the electrical energy supply of the luminous means 20 of the lamp 4 . The outer power supply line 18 , which also consists of molybdenum, has lamp-side ends 22 , 24 and is soldered to the molybdenum foils 8 , 10 via these. According to the invention, the ends 22 , 24 of the outer feeder lines 18 are bent at right angles to each other with respect to the longitudinal axes 26 of the molybdenum foils 8 , 10 . Therefore, the spacing a between the thermodynamically critical connection points of the luminous device 20 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com