Conducting wire sealing bent joint and preparation method thereof

A wire sealing and elbow joint technology, applied in the directions of sealing materials, conductive connections, electrical components, etc., can solve the problems of wire damage to wire solder joints and colloidal sealing performance, large bending space, and high requirements. The sealing performance and the effect of increasing the force bearing point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

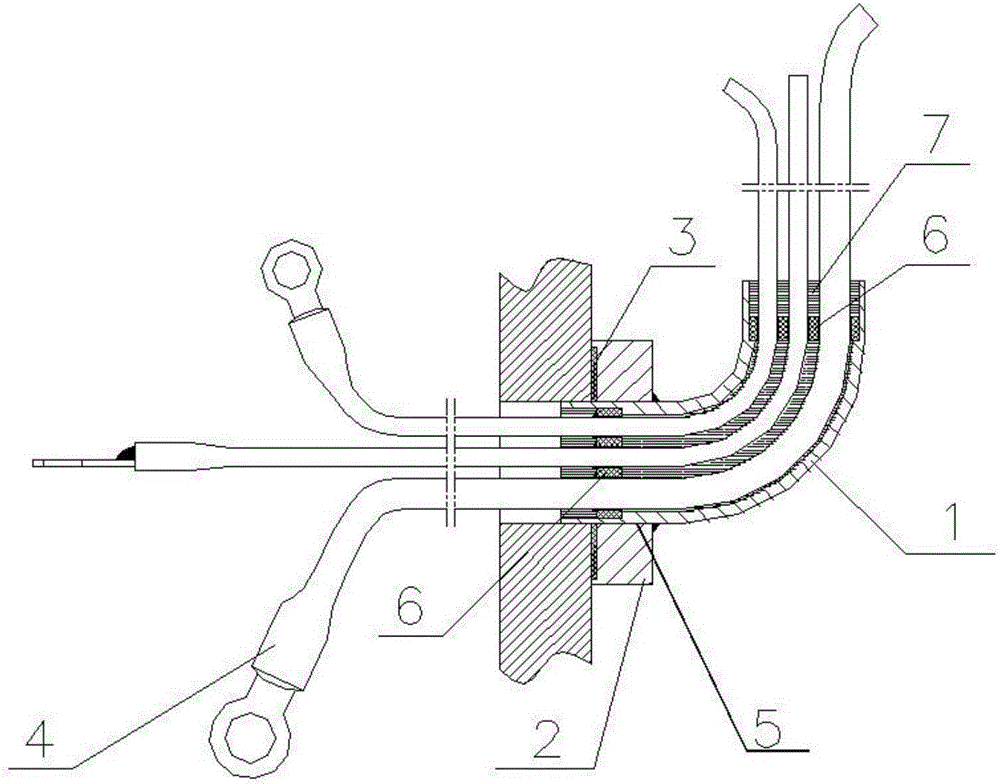

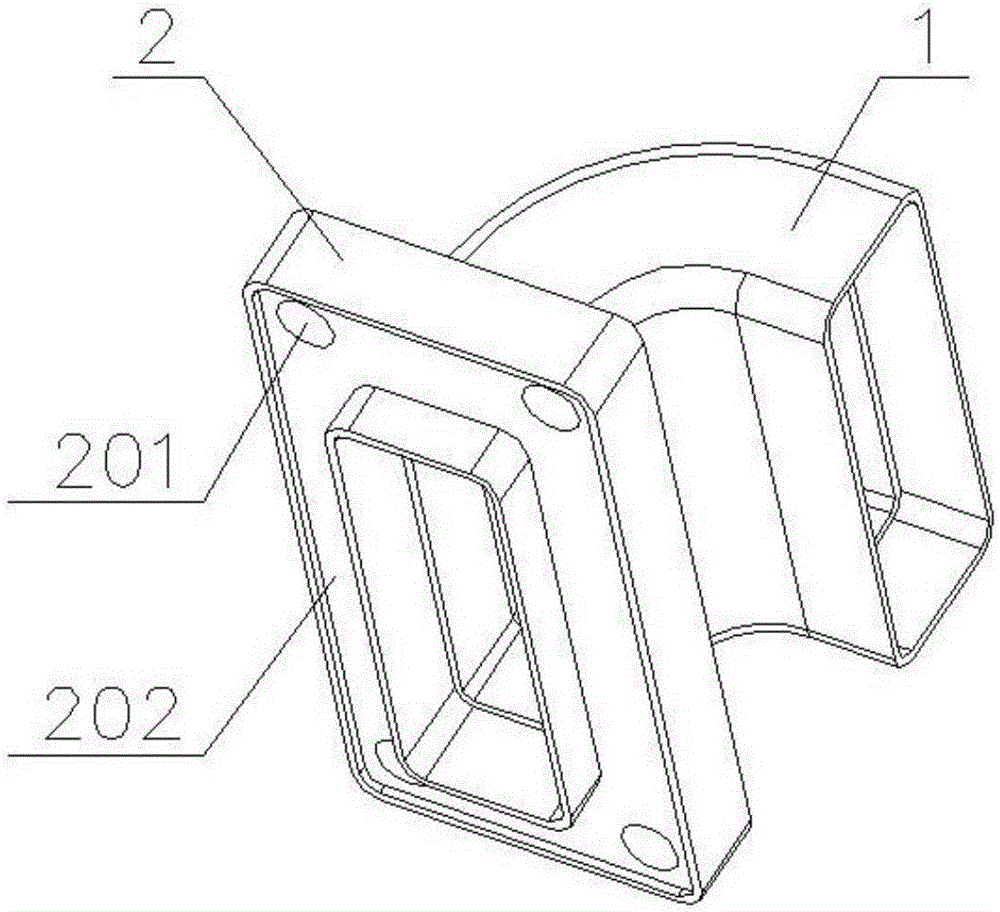

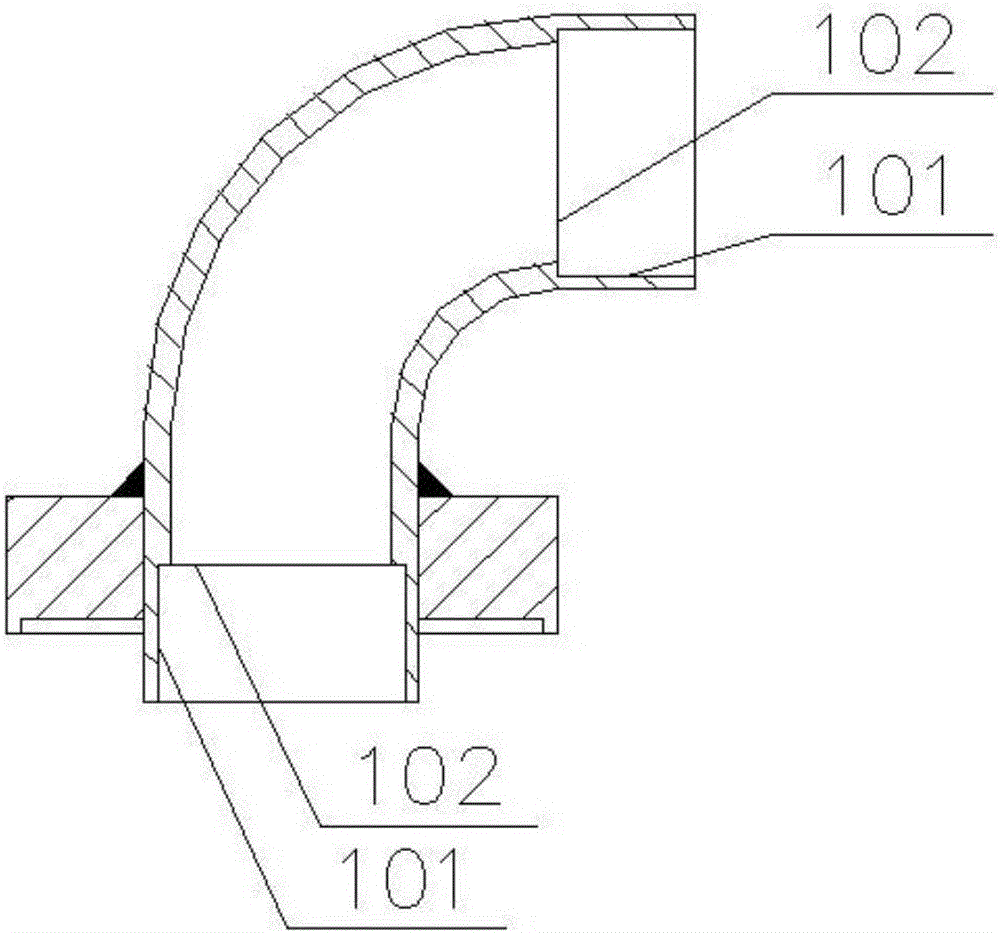

[0023] Such as Figure 1-4 As shown, a wire sealing elbow joint includes an elbow 1, a mounting seat 2 and a sealing wire 4, the inner wall 101 at both ends of the elbow 1 is provided with a limiter 102, and the mounting seat 2 is provided with a The through hole 5 matched with the elbow 1, the elbow 1 passes through the through hole 5 and is welded and fixed with the mounting base 2, and the sieve plate 6 is arranged on the limiting platform 102, and the sieve plate 6 is set There are several wire through holes 601, the sealed wire 4 passes through the wire through holes 601 and the elbow 1, a sealant 7 is injected into the elbow 1, and a mounting hole 201 is provided on the mounting base 2, A sealing limiting groove 202 is provided at the bottom end of the mounting base 2 , and a sealing gasket 3 is arranged in the sealing li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com