Line slot pre-disposing and fixing method for underground vehicle

An installation method and trunking technology, applied in the direction of electrical components, etc., can solve the problems of increasing operating difficulty and fatigue of operators, long installation time, etc., and achieve the effect of improving the installation environment, reducing the difficulty of installation, and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

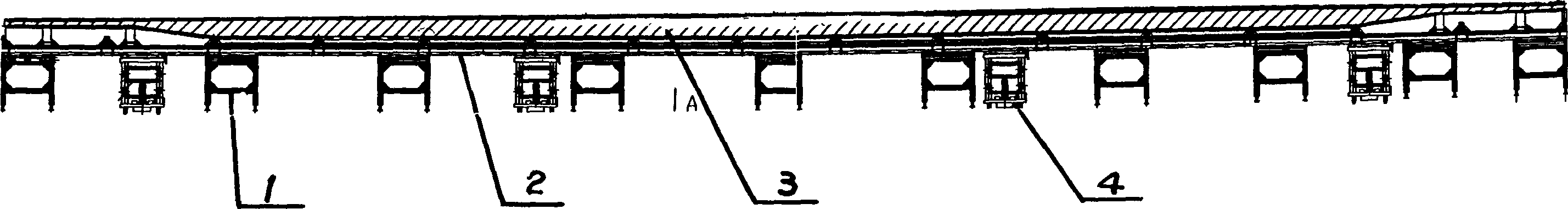

[0017] like figure 1 Shown is a kind of pre-distribution and installation device for wire slots on the underframe of subway vehicles using the method of the present invention. 2, and it is composed of the wire slot 3 on the pre-distribution workbench, and it is characterized in that: the lower part of the pre-distribution work platform 2 is provided to synchronize the pre-distribution work platform 2 with the pre-wiring groove 3 on it Lifting mobile trolley 4 that jacks up and moves.

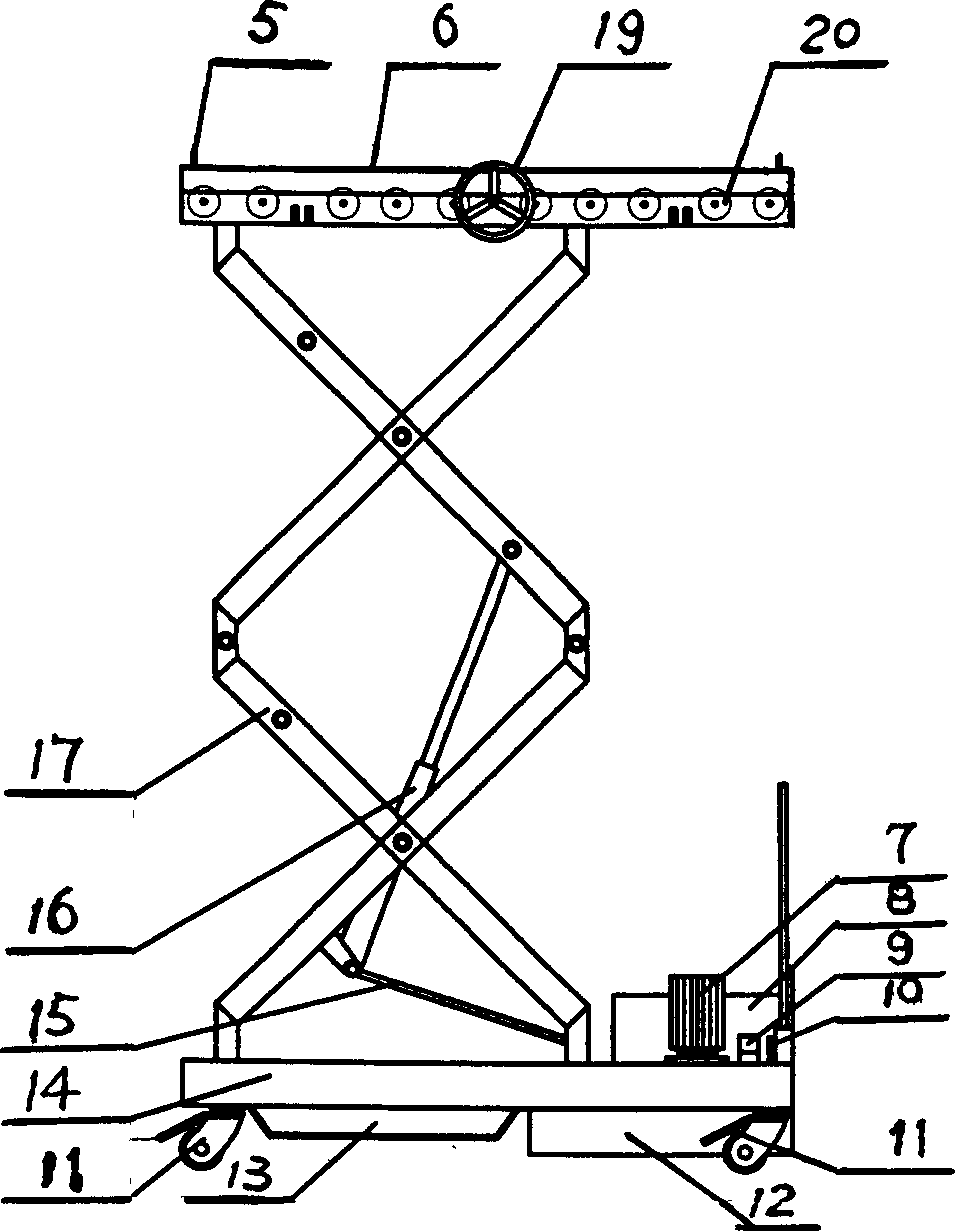

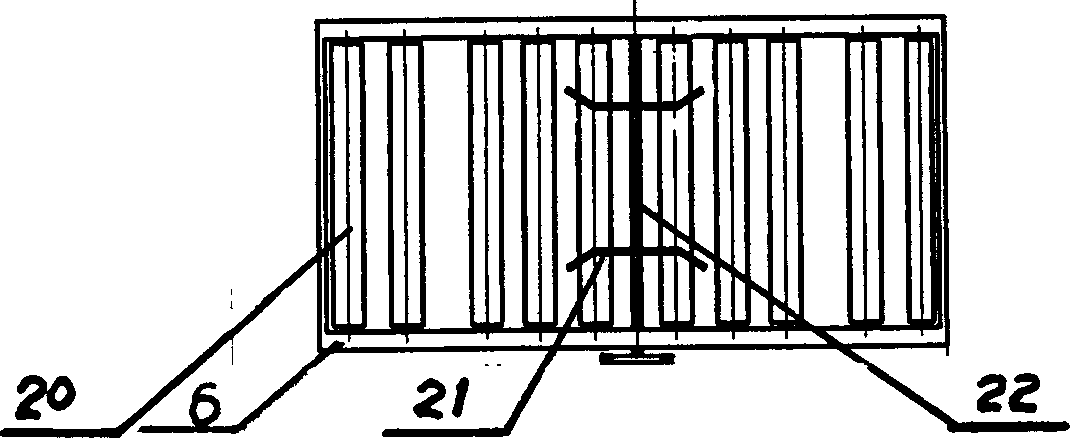

[0018] figure 2 The hydraulic lifting mobile trolley shown is composed of a base 14 with universal wheels 11, a lifting arm 17, a motor 7, and a fuel tank 12 forming a hydraulic lifting mechanism, a control box 8, a solenoid valve 9, an oil pressure gauge 10, an anti-seepage The oil box 13 is composed of an oil delivery pipe 15 and an oil pressure ejector rod 16, etc. It is characterized in that: the upper part of the base 14 is provided with an X-shaped lifting arm 17 that is fixed with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com