Application of high-voltage variable-frequency and variable-speed system in shaft hoist

A technology of mine hoist and speed regulation system, which is applied in the control system, motor/generator/inverter limiter, motor generator control, etc. problems such as poor speed quality, to achieve the effect of improving power factor, improving efficiency, and improving speed regulation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

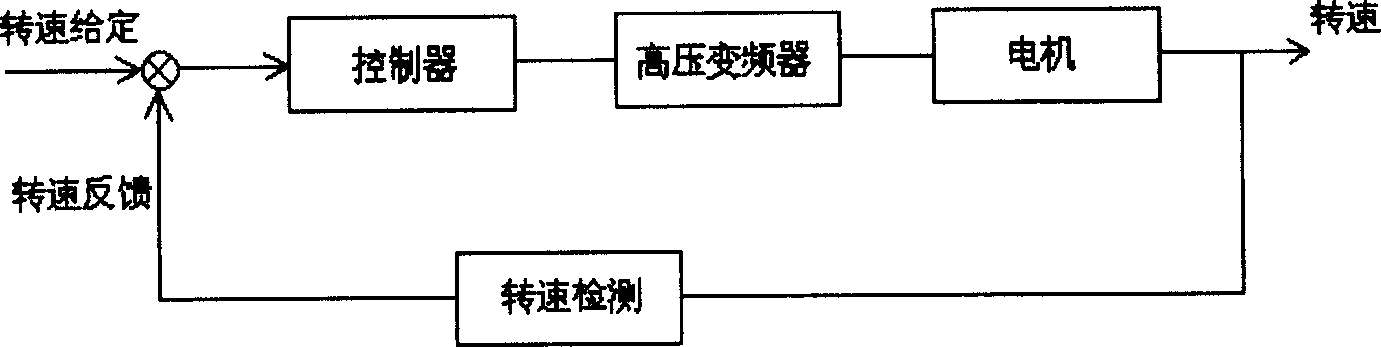

[0020] See figure 1 , the application of high-voltage frequency conversion speed regulation system in mine hoist, its control strategy adopts asynchronous motor flexible traction closed-loop, the controller sends out appropriate frequency amplitude and three-phase sinusoidal signal command according to the error between speed given and speed feedback , the command is sent to the high-voltage inverter, which outputs AC power meeting the above requirements through the high-voltage inverter to drive the motor to run, so that the running performance strictly meets the requirements of the given speed.

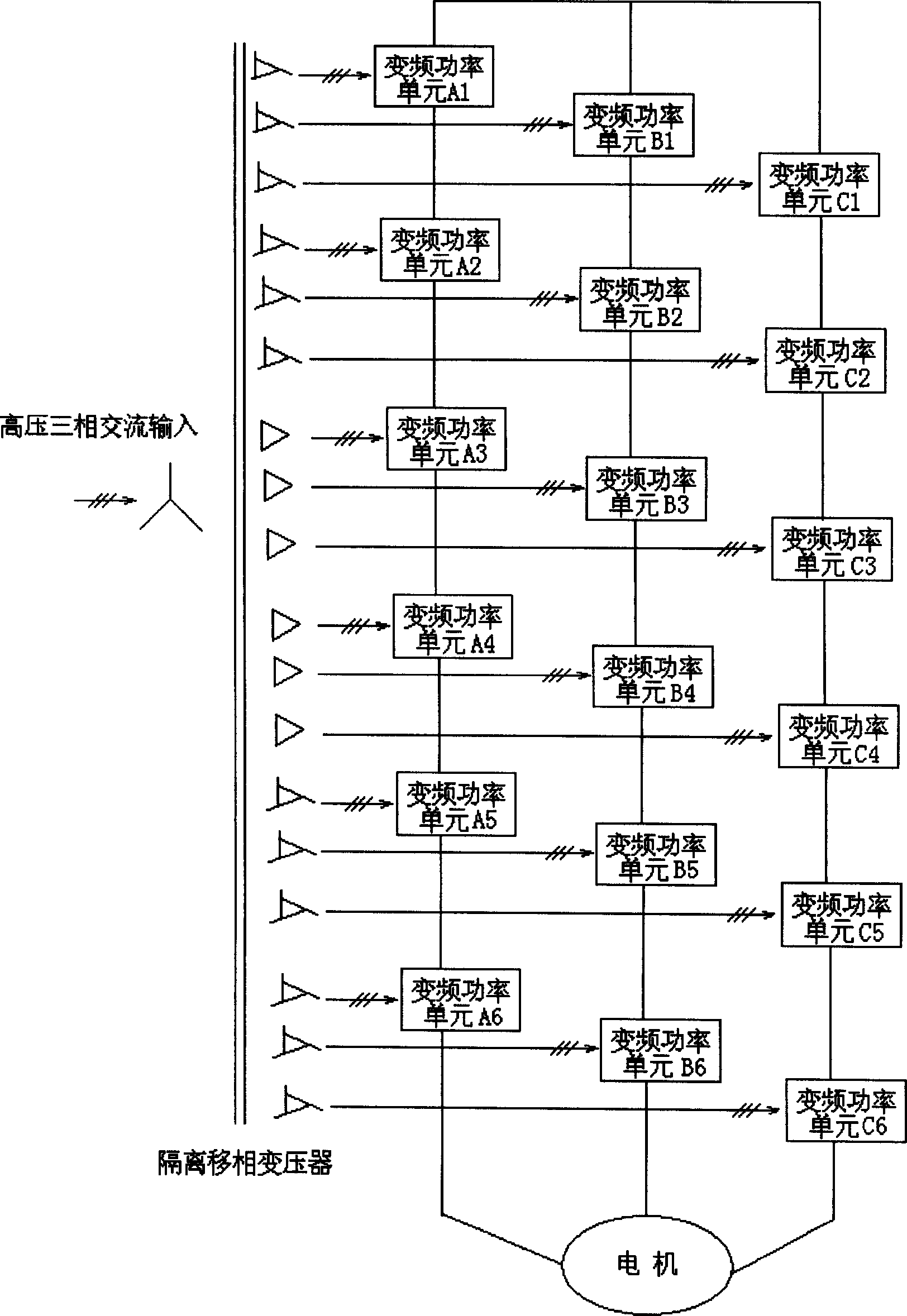

[0021] The high-voltage frequency conversion speed regulation system adopts the high-performance, mature technology, safe and reliable input isolation transformer-H bridge unit series multi-level technical scheme and the flexible traction closed-loop method of asynchronous motor, which can realize the forward and reverse traction braking of the motor.

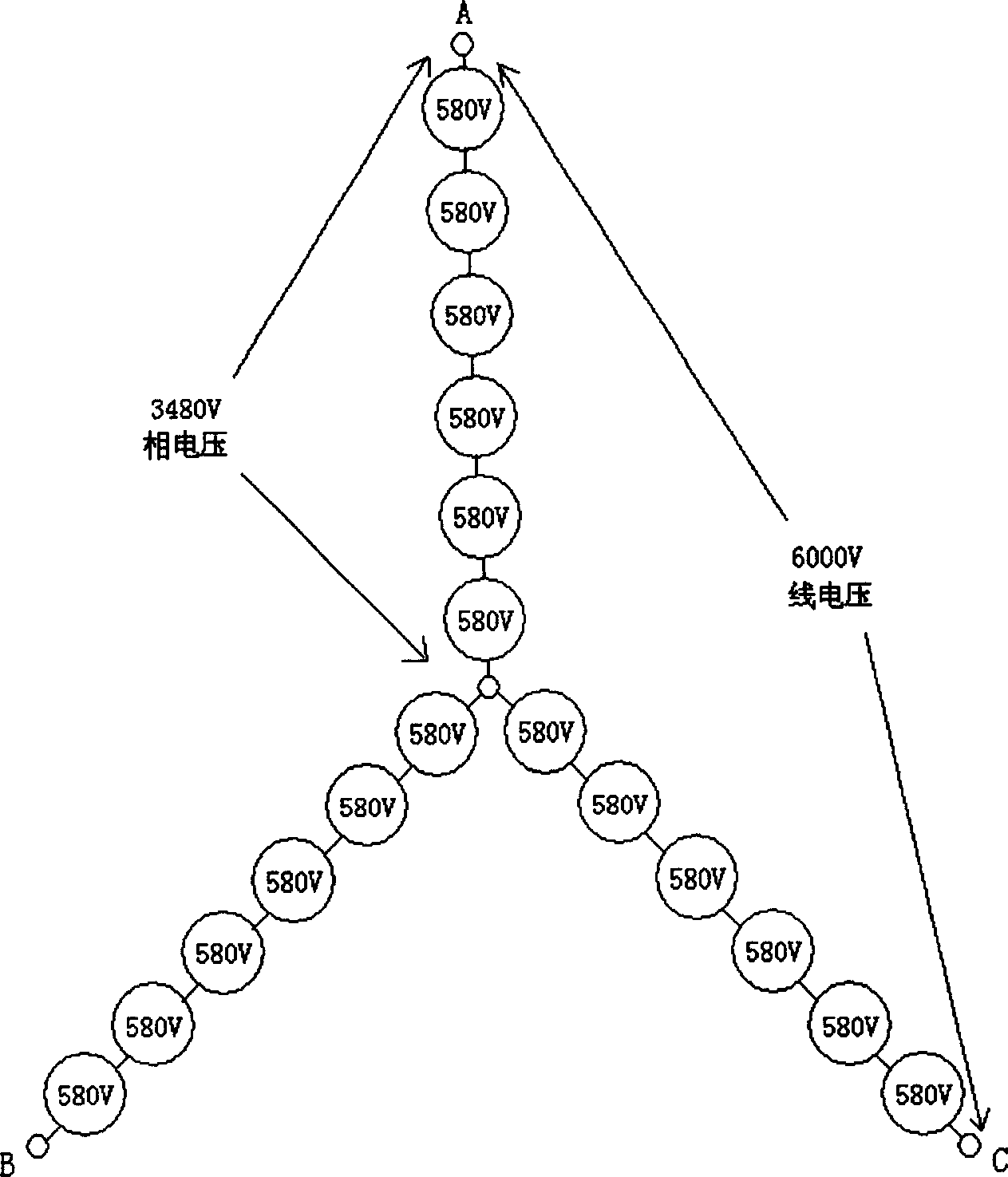

[0022] See figure 2 , the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com