Antibacterial polyethylene composition and preparation method thereof

A composition, polyethylene technology, applied in the field of polyethylene plastic processing, can solve the problems of unfavorable load use, short service life, easy to move out, etc., to achieve prolonged effectiveness and water resistance, improve antibacterial efficiency, and solve poor compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

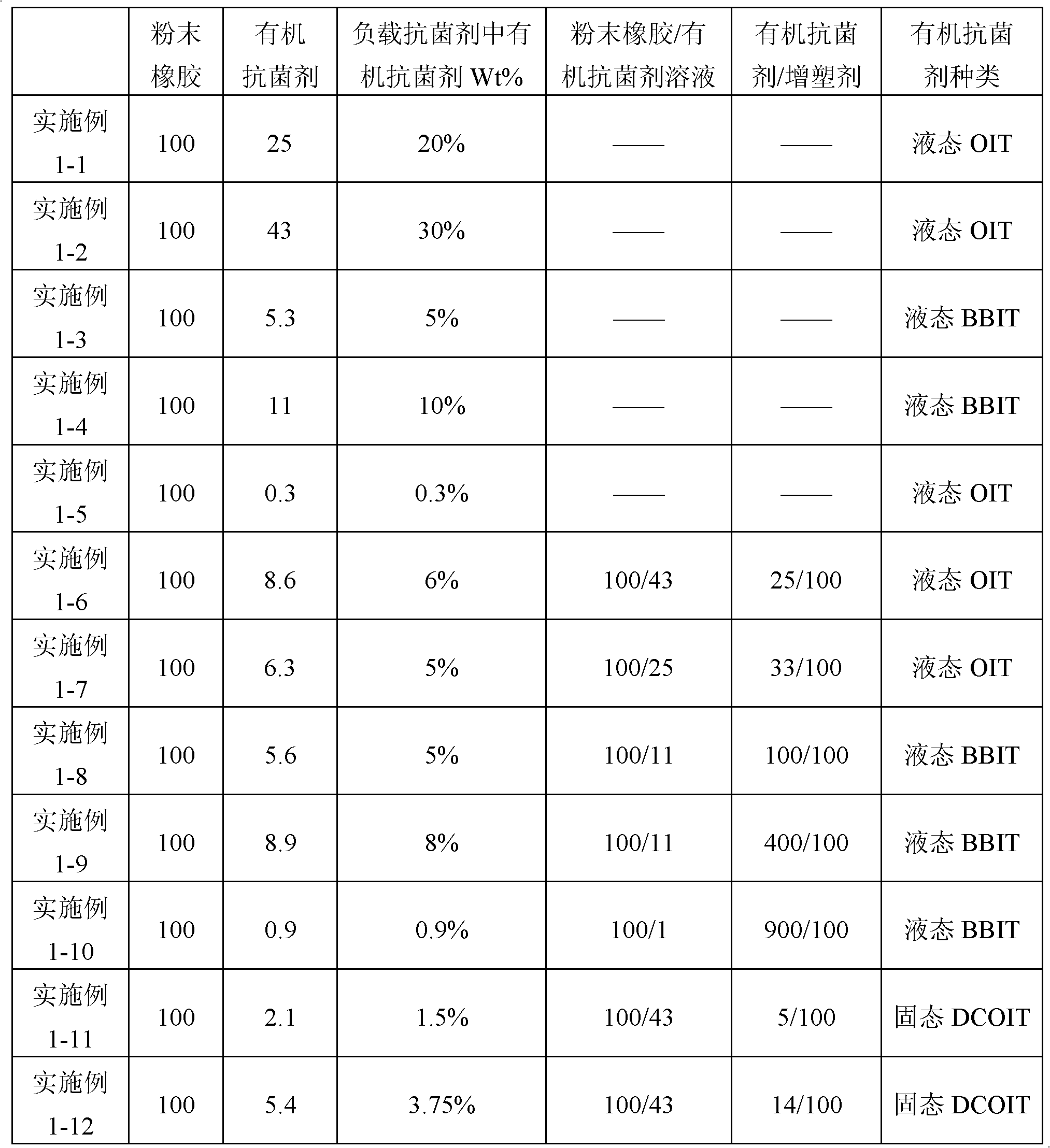

Examples

Embodiment 1-1

[0073]Weigh 80 g of fully vulcanized styrene-butadiene powder rubber (VP101, gel content 80% wt), 2-n-octyl-4-isothiazol-3-ketone (OIT) 20 g, stir it in a mixer until uniformly mixed, and let stand After 2 hours, it was taken out to obtain an antibacterial agent (VP101KJ-1) loaded with OIT by fully vulcanized styrene-butadiene powder rubber. See Table 1 for parts by weight or weight ratio of each component.

Embodiment 1-2

[0075] Weigh 70g of fully vulcanized styrene-butadiene powder rubber (VP101, gel content 85%wt), 2-n-octyl-4-isothiazol-3 ketone (OIT) 30g, stir it in a mixer until uniformly mixed, let stand After 2 hours, it was taken out to obtain an antibacterial agent (VP101KJ-2) loaded with OIT by fully vulcanized styrene-butadiene powder rubber. See Table 1 for parts by weight or weight ratio of each component.

Embodiment 1-3

[0077] Weigh 95g of fully vulcanized carboxylated styrene-butadiene powder rubber (VP201, gel content 85%wt), 5g of n-butylbenzisothiazolinone (BBIT), stir it in a mixer until it is evenly mixed, and take it out after standing for 3h , to obtain fully vulcanized styrene-butadiene powder rubber-loaded BBIT antibacterial agent (VP201KJ-3). See Table 1 for parts by weight or weight ratio of each component.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com