Button-sewing machine

A button sewing machine and sewing thread technology, applied in the field of button sewing machines, can solve problems such as complicated operations, reduced operating efficiency, and reduced commodity value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

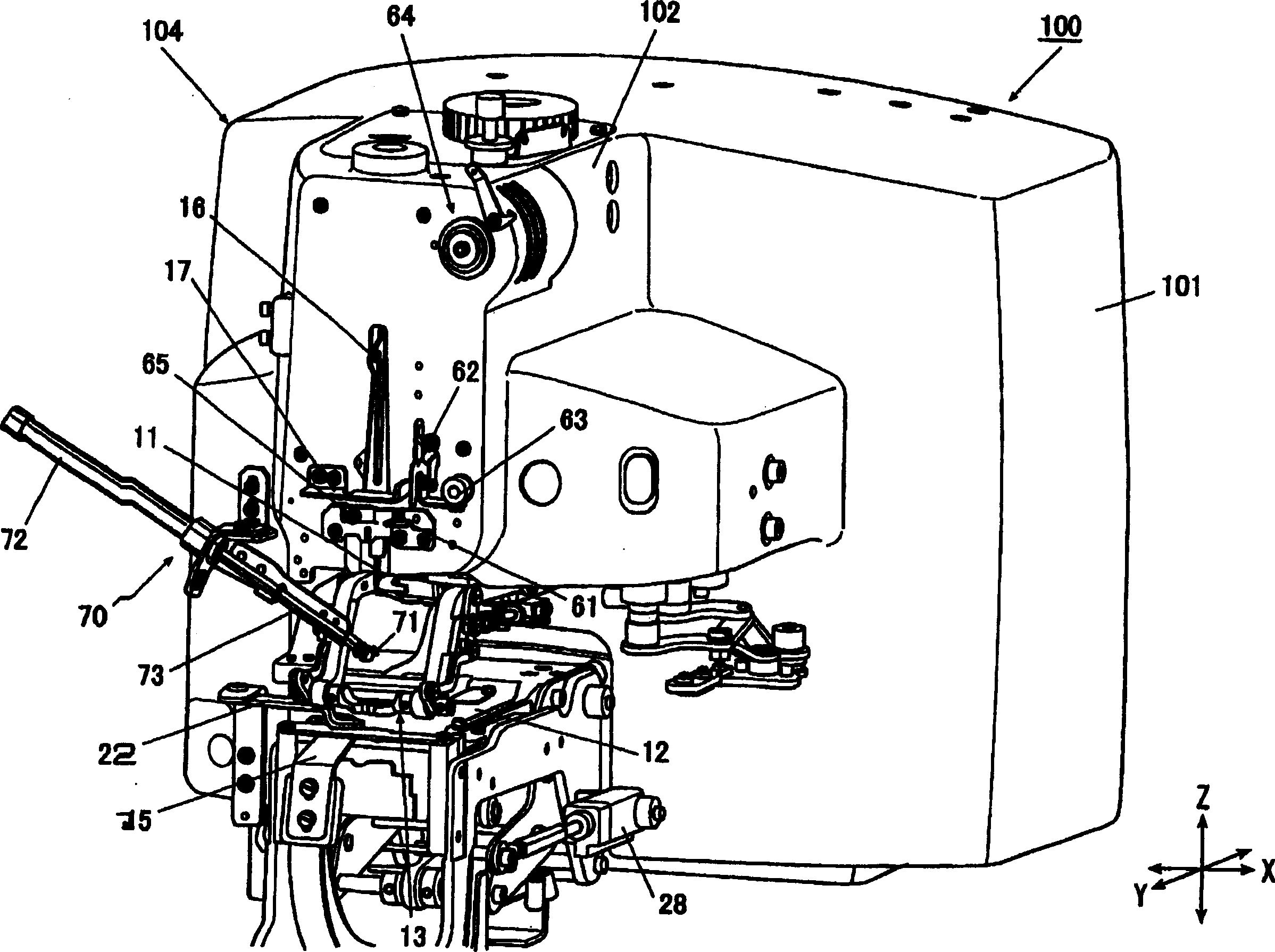

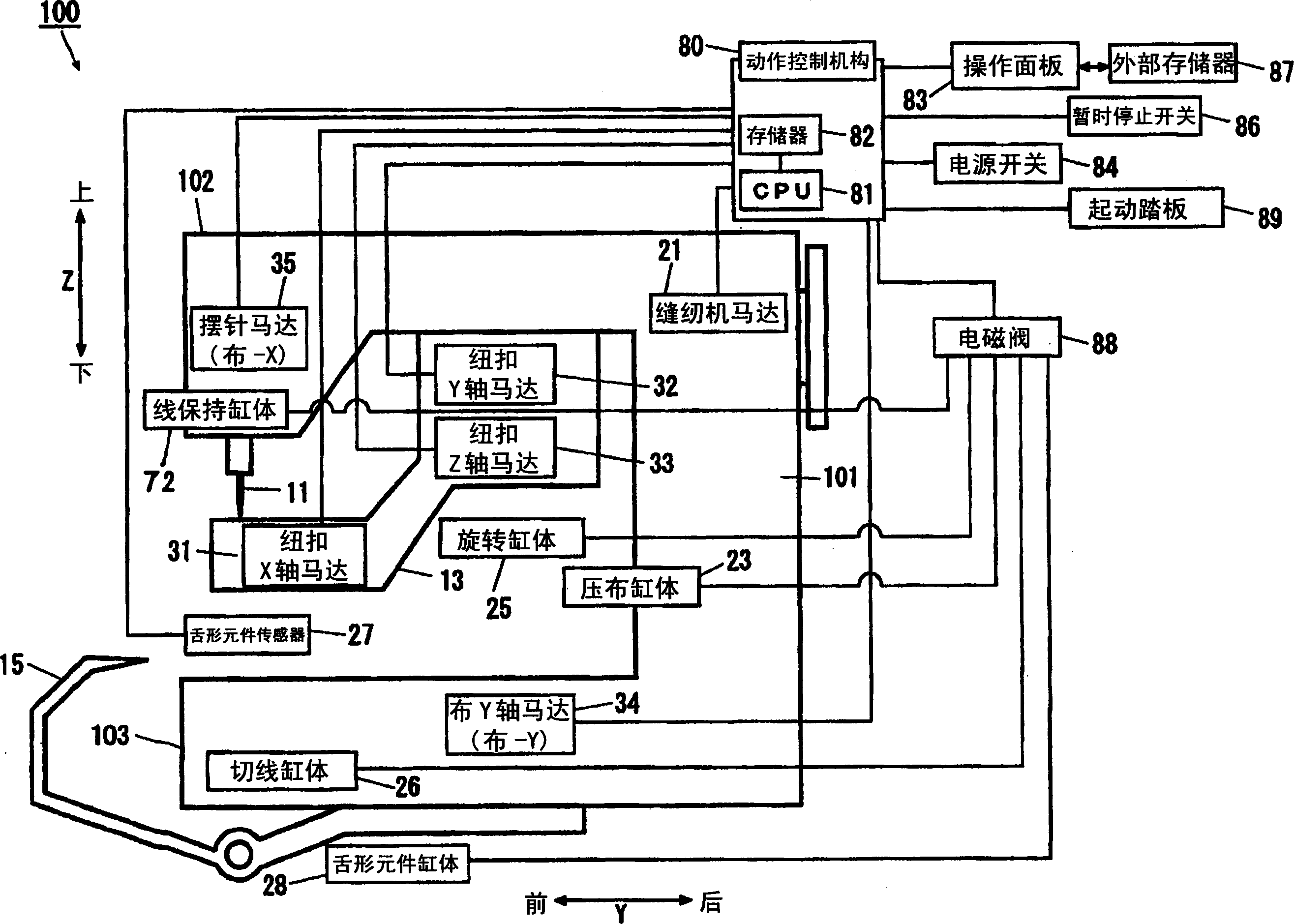

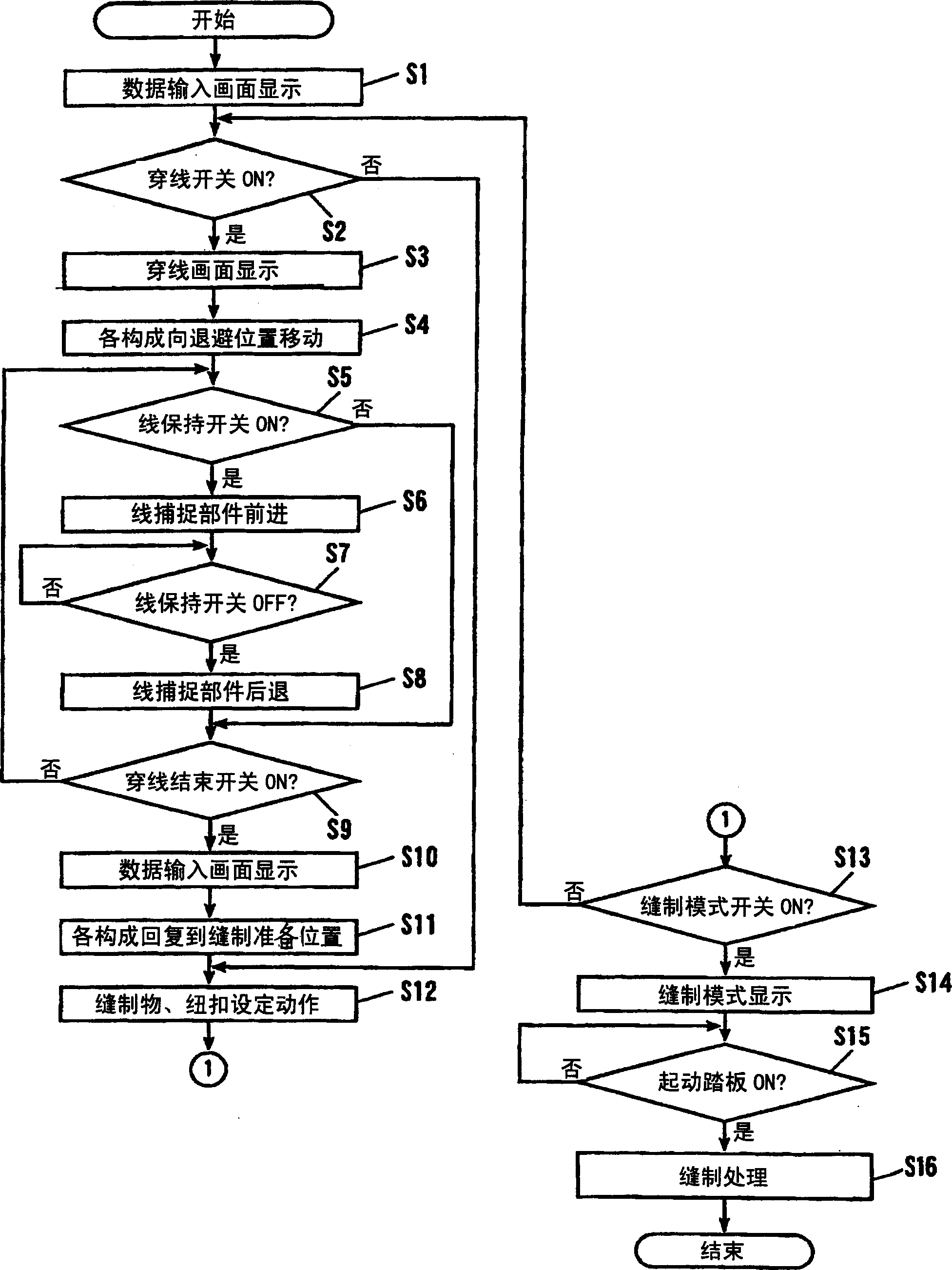

[0031] Below, based on Figure 1 to Figure 6 , the button sewing machine 100 according to the embodiment of the present invention will be described.

[0032] figure 1 It is a perspective view showing the main configuration of the button sewing machine 100 . figure 2 It is a block diagram showing the main configuration of the button sewing machine 100 .

[0033] The button sewing machine 100 is a sewing machine for fastening a button to a cloth with a sewing thread through the cooperation of a vertically moving needle 11 and a looper (not shown).

[0034] The button sewing machine 100 is composed of a sewing machine base plate 103 located at its lower portion, a sewing machine vertical body portion 101 erected upward from one end portion behind the sewing machine base plate 103, and a sewing machine vertical body portion 101 along the sewing machine base plate from above the sewing machine vertical body portion 101. 103 and extend the sewing machine head 102 that is arrange...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap