Structural beam and post made of small-diameter profiled larch veneer

A technology of structural beams and unit materials, applied in truss structures, columns, joists, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

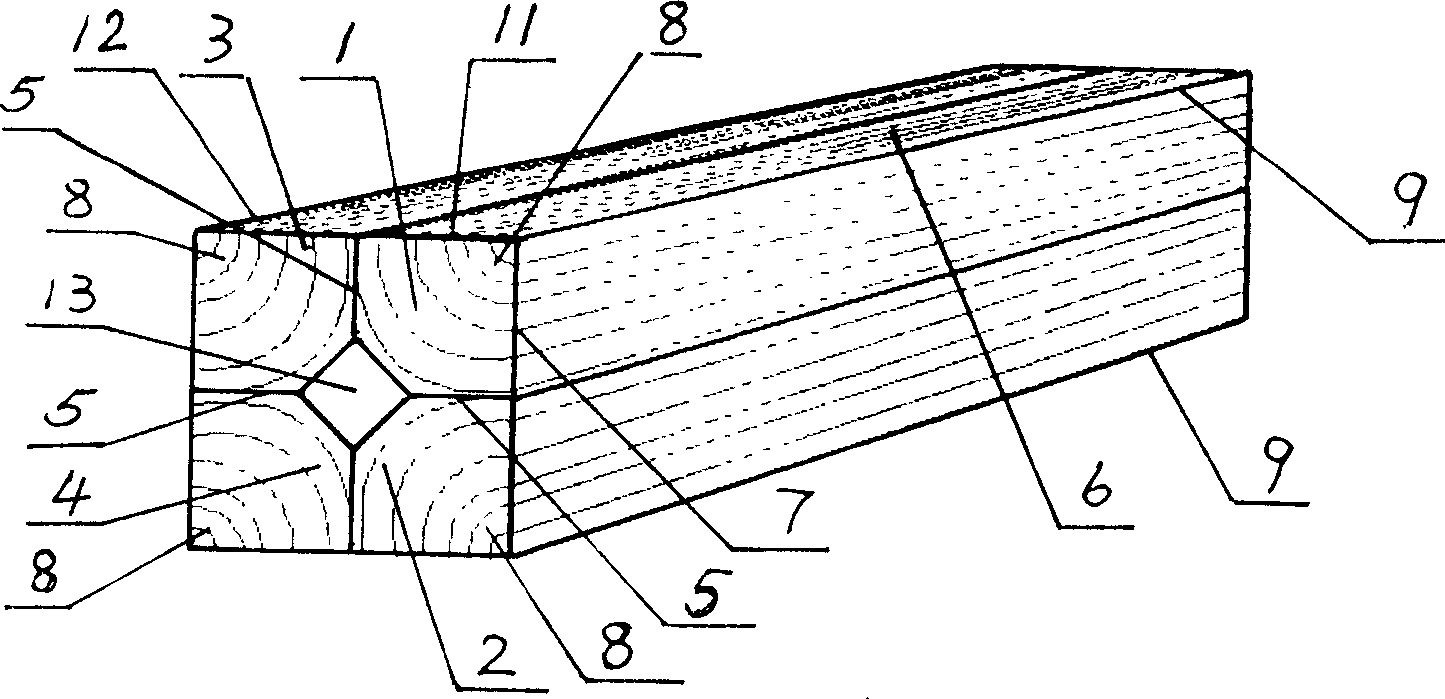

[0005] Specific implementation mode one: (see figure 1 , Figure 2) This embodiment is composed of the first quarter unit material 1, the second quarter unit material 2, the third quarter unit material 3 and the fourth quarter unit material 4, the first quarter unit material 4 The first quarter unit material 1 and the second quarter unit material 2 are bonded and fixed by resin glue 5 to form the first half laminated material 11, the third quarter unit material 3 and the fourth quarter unit material. One unit material 4 is bonded and fixed by resin glue 5 to form the second half laminated material 12, and the first half laminated material 11 and the second half laminated material 12 are formed by bonding and fixing resin glue 5 The columnar body 6, the cross section of the columnar body 6 is a rectangle 7. The production method of this embodiment is as follows: using the existing lumber making equipment, through the pith sawing method (that is, cutting the small-diameter wood ...

specific Embodiment approach 2

[0006] Specific implementation mode two: (see figure 1 , FIG. 2) The difference between this embodiment and the first embodiment is that the wood core 8 of each quarter unit is arranged on the outer corner 9 of the columnar body 6 whose cross section is a rectangle 7 . Other compositions and connections are the same as in the first embodiment. Quarter-sawn lumber is obtained by sawing down the pith, and its strength is higher than that of non-diameter-sawn lumber. The integrated wooden beams and columns after re-integration and gluing have anisotropy, which reduces the deformation of the material and effectively prolongs the life of the material. service life.

specific Embodiment approach 3

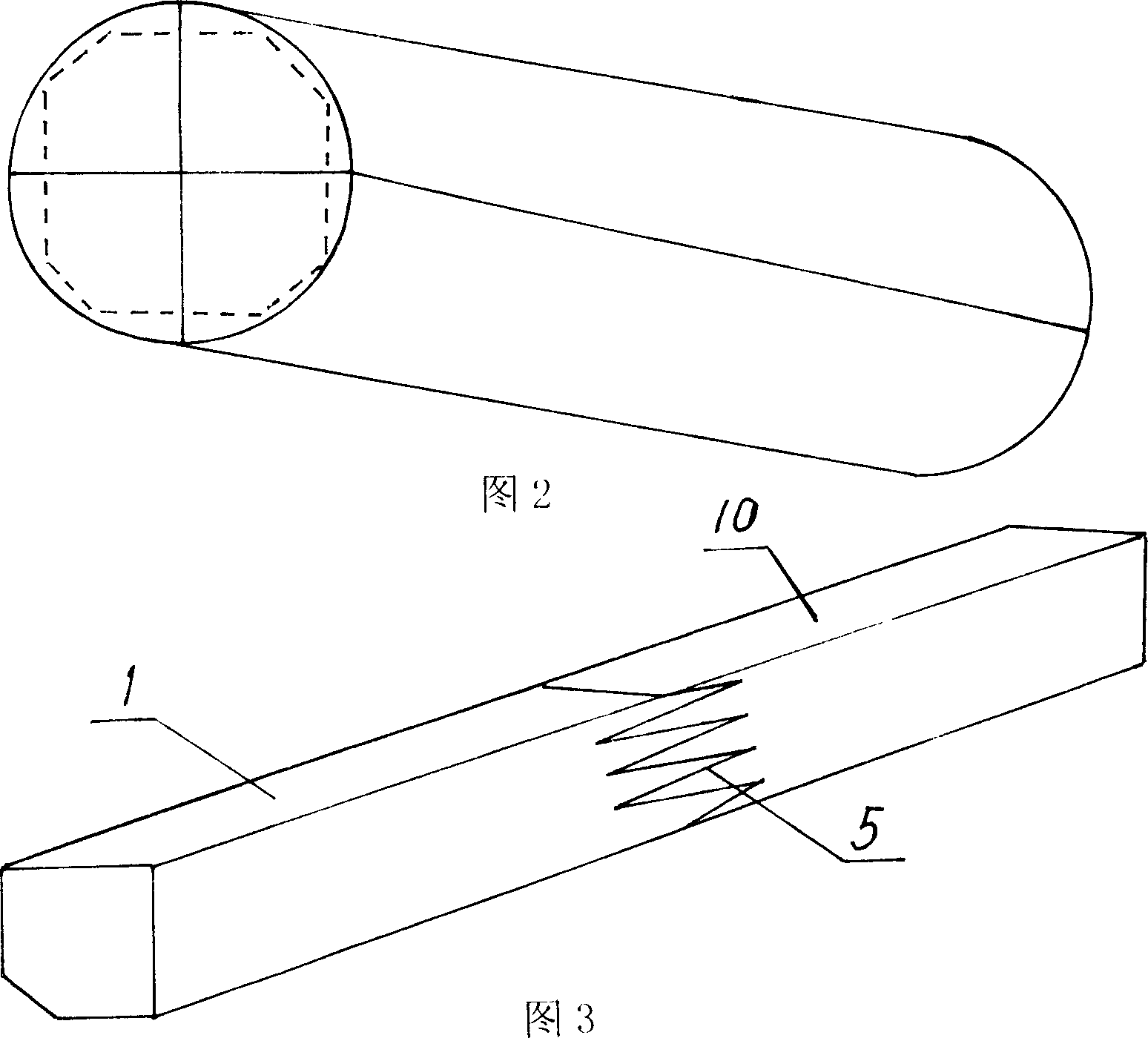

[0007] Specific embodiment three: (see Fig. 3) the difference between this embodiment and specific embodiment one or two is that it increases the fifth quarter unit material 10, and one end of the fifth quarter unit material 10 is connected to One end of the first quarter element 1 is finger-jointed and fixed by resin glue 5 . Form a lengthened quarter unit material, use the lengthened quarter unit material to carry out integrated gluing of one-half integrated wooden beams (columns), and then complete the integration by two half-integrated wooden beams (columns) The integrated gluing of integrated wooden beams (columns) promptly obtains elongated small-diameter special-shaped unit timber gluing structural beams (columns). This implementation method can fully expand the application range of small-diameter larch, and the short unit materials can be lengthened by finger-joining; the unit-integrated wooden beams (columns) can be glued into a longer structure by means of gluing and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com