Electronic ballast applicable to 400V/600W high voltage sodium lamps for agricultural use

A technology for electronic ballasts and high-pressure sodium lamps, which is applied to electric light sources, electrical components, lighting devices, etc., can solve the problem that electronic ballasts cannot be applied to 400V/600W agricultural high-pressure sodium lamps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

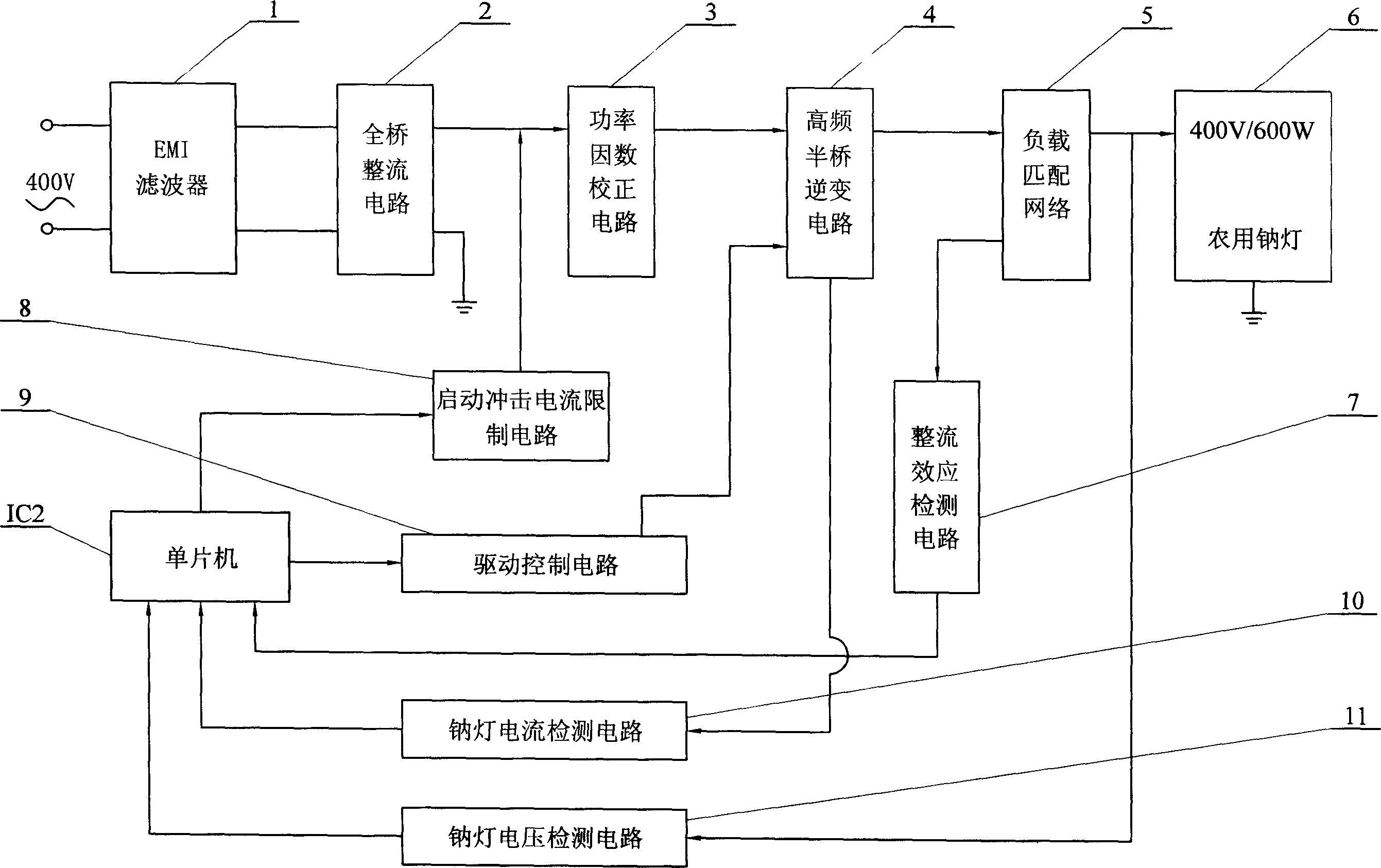

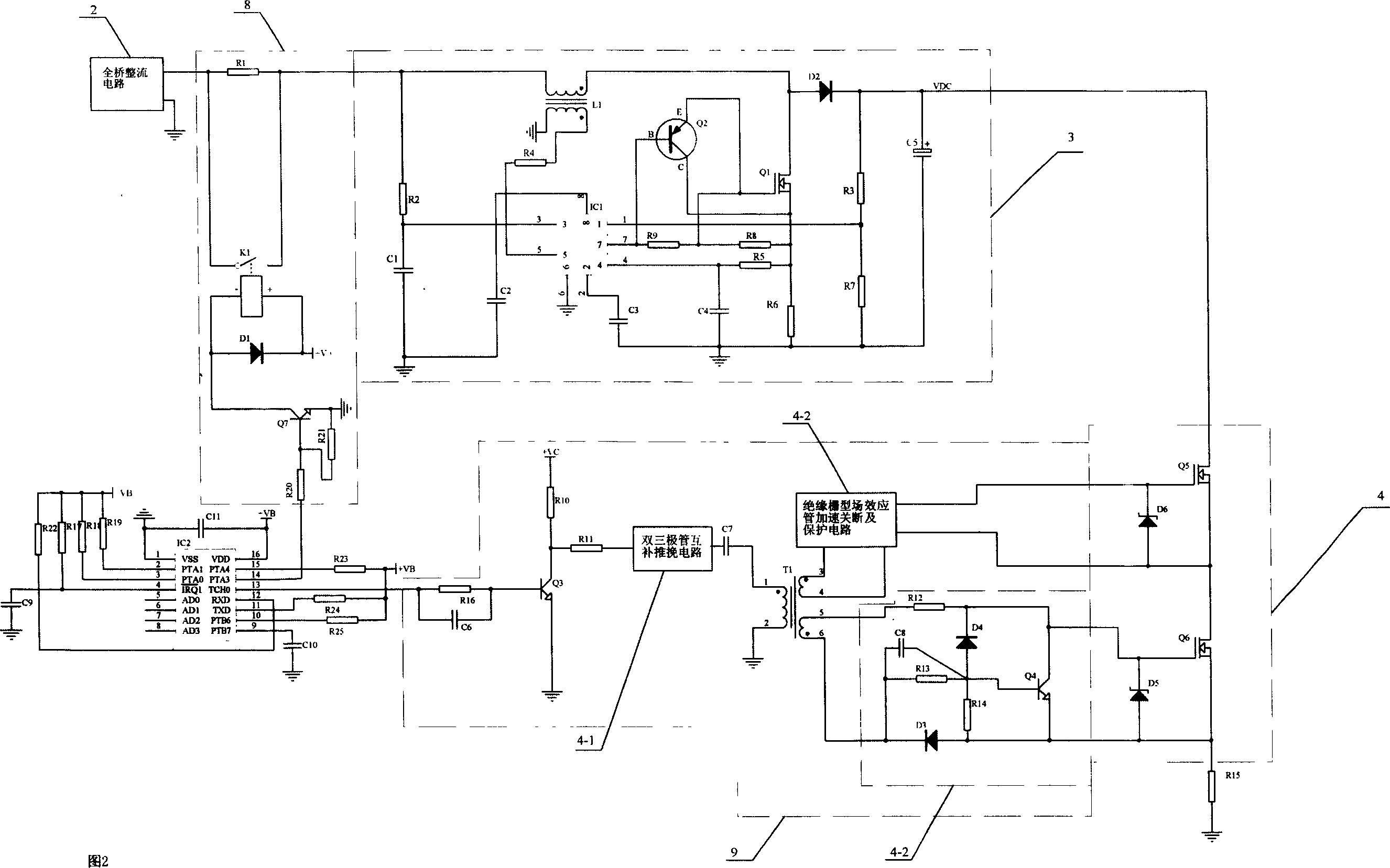

specific Embodiment approach 1

[0007] Specific implementation mode one: see figure 1 , the specific embodiment consists of EMI filter 1, full bridge rectifier circuit 2, power factor correction circuit 3, high frequency half bridge inverter circuit 4, load matching network 5, 400V / 600W agricultural sodium lamp 6, start inrush current limiting circuit 8 , single-chip microcomputer IC2, drive control circuit 9 and rectification effect detection circuit 7, the two output terminals of the 400V AC power supply are respectively connected to the two power supply input terminals of the EMI filter 1, and the two output terminals of the EMI filter 1 are respectively connected to the full bridge The two input ends of the rectification circuit 2, one output end of the full bridge rectification circuit 2 are grounded, the other output end of the full bridge rectification circuit 2 is connected to the DC power input end of the power factor correction circuit 3, and the output end of the power factor correction circuit 3 ...

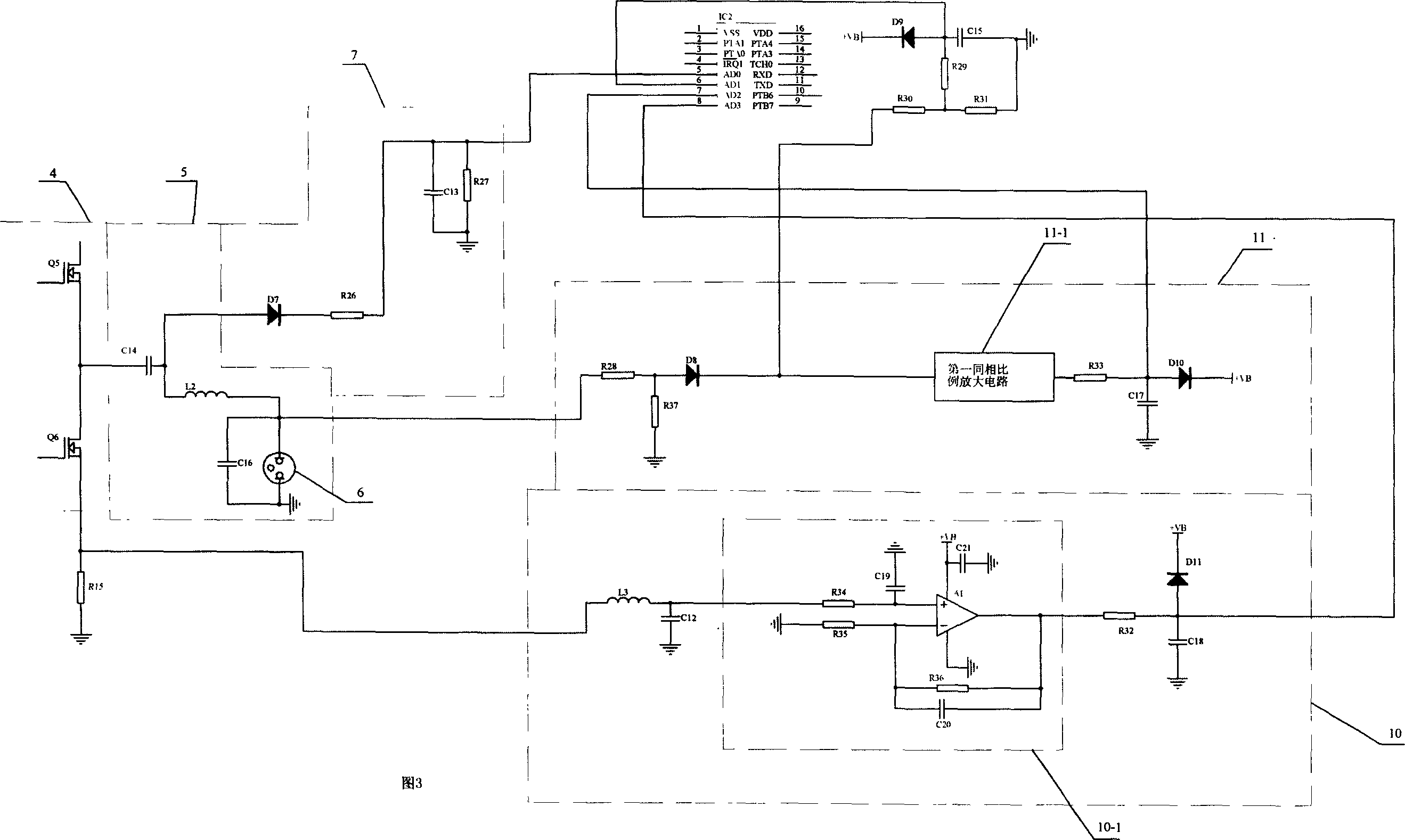

specific Embodiment approach 2

[0008] Specific implementation mode two: see figure 1 The difference between this embodiment and Embodiment 1 is that it also includes a sodium lamp current detection circuit 10, the output end of the current detection signal of the high-frequency half-bridge inverter circuit 4 is connected to the input end of the sodium lamp current detection circuit 10, and the sodium lamp current The output end of the detection circuit 10 is connected to the current detection signal input end of the single-chip microcomputer IC2. Other components and connections are the same as those in the first embodiment. The real-time monitoring of the current in the sodium lamp is realized by using the single-chip microcomputer IC2.

specific Embodiment approach 3

[0009] Specific implementation mode three: see figure 1 The difference between this embodiment and Embodiment 1 is that it also includes a sodium lamp voltage detection circuit 11, the voltage input end of the 400V / 600W agricultural sodium lamp 6 is connected to the input end of the sodium lamp voltage detection circuit 11, and the sodium lamp voltage detection circuit 11 The output terminal is connected to the voltage detection signal input terminal of the single chip microcomputer IC2. Other components and connections are the same as those in the first embodiment. The real-time monitoring of the voltage in the sodium lamp is realized by using the single-chip microcomputer IC2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com