Pressure injection-moulded hot melt sealed pipe joint and sealing method thereof

A technology of hot-melt sealing and pipe joints, which is applied in the direction of non-detachable pipe connections, pipes/pipe joints/fittings, passing components, etc., which can solve the problems of easy damage to the butt joint rubber ring, complicated butt joint operation, and high joint cost to achieve sealing Effective effect, wide application range and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

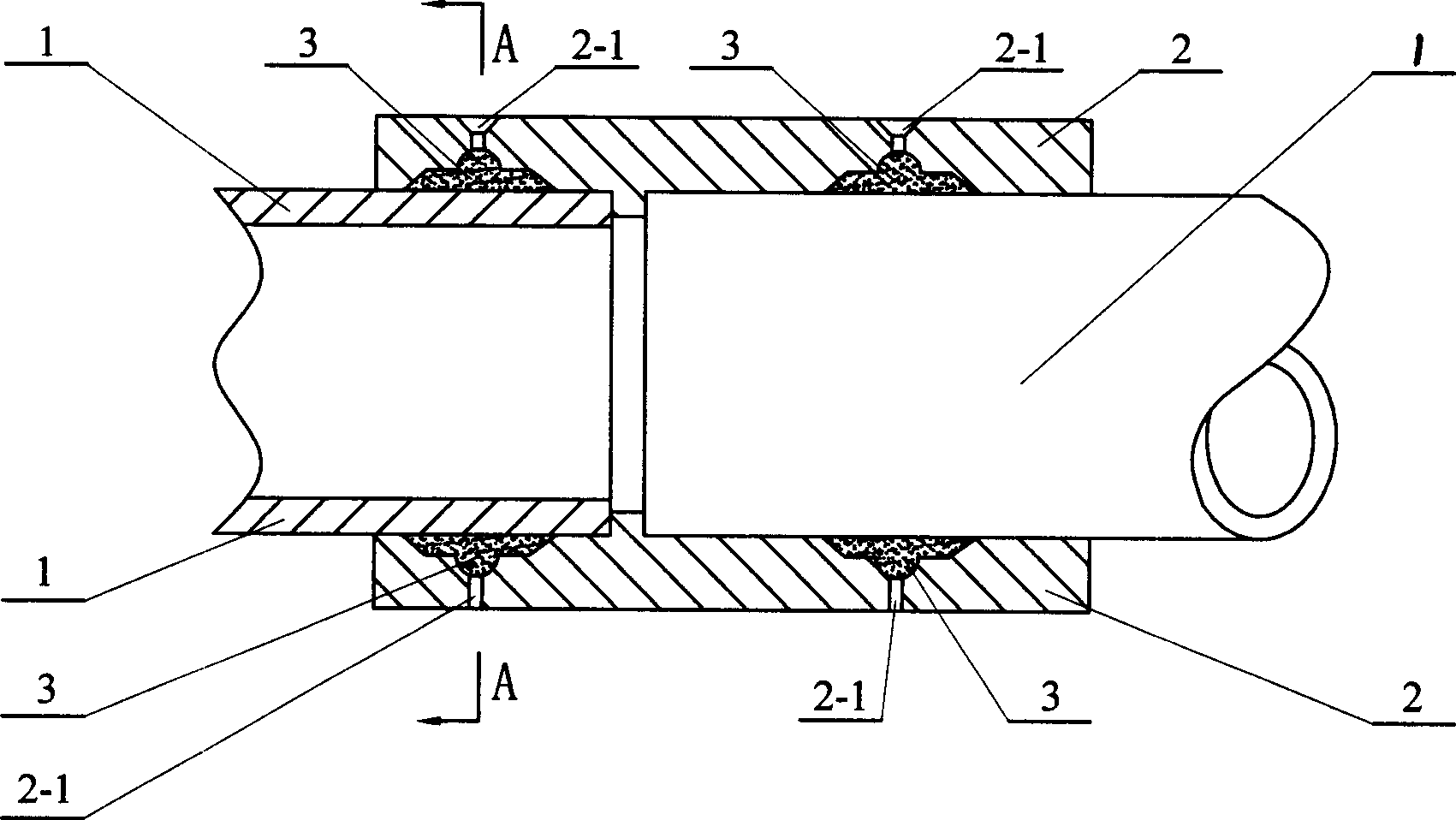

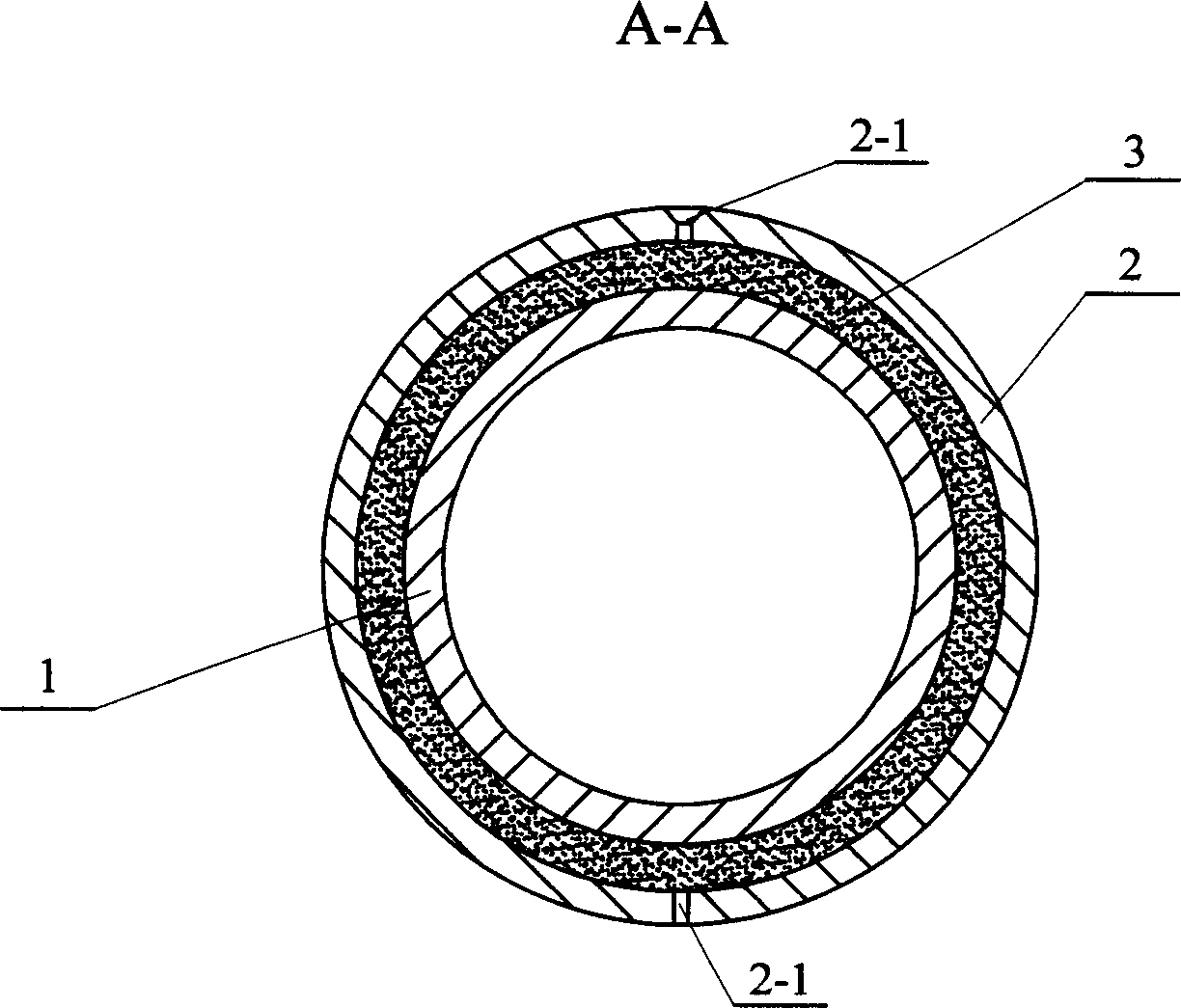

[0010] Specific implementation mode one: see figure 1 and figure 2 The pressure injection molded hot-melt sealed pipe joint of this specific embodiment is composed of a connecting pipe fitting 2 and a hot-melt adhesive layer 3, and at least two pairs of radial melt glue injections are provided at different positions on the outer wall of the connecting pipe fitting 2 in the axial direction. In hole 2-1, a hot melt adhesive layer 3 is solidified in the gap between the outer surface of the butt end of the pipe 1 and the inner surface of the connecting pipe.

specific Embodiment approach 2

[0011] Specific implementation mode two: see figure 1 and figure 2 The difference between this embodiment and Embodiment 1 is that: the inner surface of the connecting pipe 2 is provided with at least one ring-shaped flow channel, and the ring-shaped flow channel is connected to a pair of radial melt injection holes 2- 1 is connected, and a hot melt adhesive layer 3 is solidified in the cavity of the annular flow channel. The annular flow channel of the above-mentioned connecting pipe fittings and a pair of pouring holes together constitute an annular cavity with a socket on the bonding surface. When the hot melt adhesive is sprayed into the annular flow channel through the filling hole, the hot melt adhesive will flow along the flow channel Flow until the entire annular cavity is filled, and then cool and solidify to form a hot melt adhesive layer. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0012] Specific implementation mode three: see figure 1 and figure 2 The difference between this specific implementation and specific embodiment 1 is: a pair of radial melt glue injection holes 2-1 are respectively provided on the outer walls of the first and last ends of the connecting pipe fitting 2, and the first and last of the connecting pipe fitting 2 The inner surfaces of both ends are respectively provided with a circle of annular flow passages, the annular flow passages on the inner surface of the head end of the connecting pipe fitting 2 communicate with a pair of radial melt injection holes 2-1 on the outer wall of the head end, and the connecting pipe fittings 2. The annular flow channel on the inner surface of the end communicates with a pair of radial melt injection holes 2-1 on the outer wall of the end. Other compositions and connections are the same as in the first embodiment. This specific embodiment can be used to connect the butt ends of two pipelines. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com