Sealing components of submarine cable

A technology for sealing components and underwater cables, which is applied to cable joints, electrical components, parts of connecting devices, etc., can solve the problems of inability to perform maintenance on site, stalled maintenance operations, and poor maintainability, and achieves simple and easy structure. Easy maintenance and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

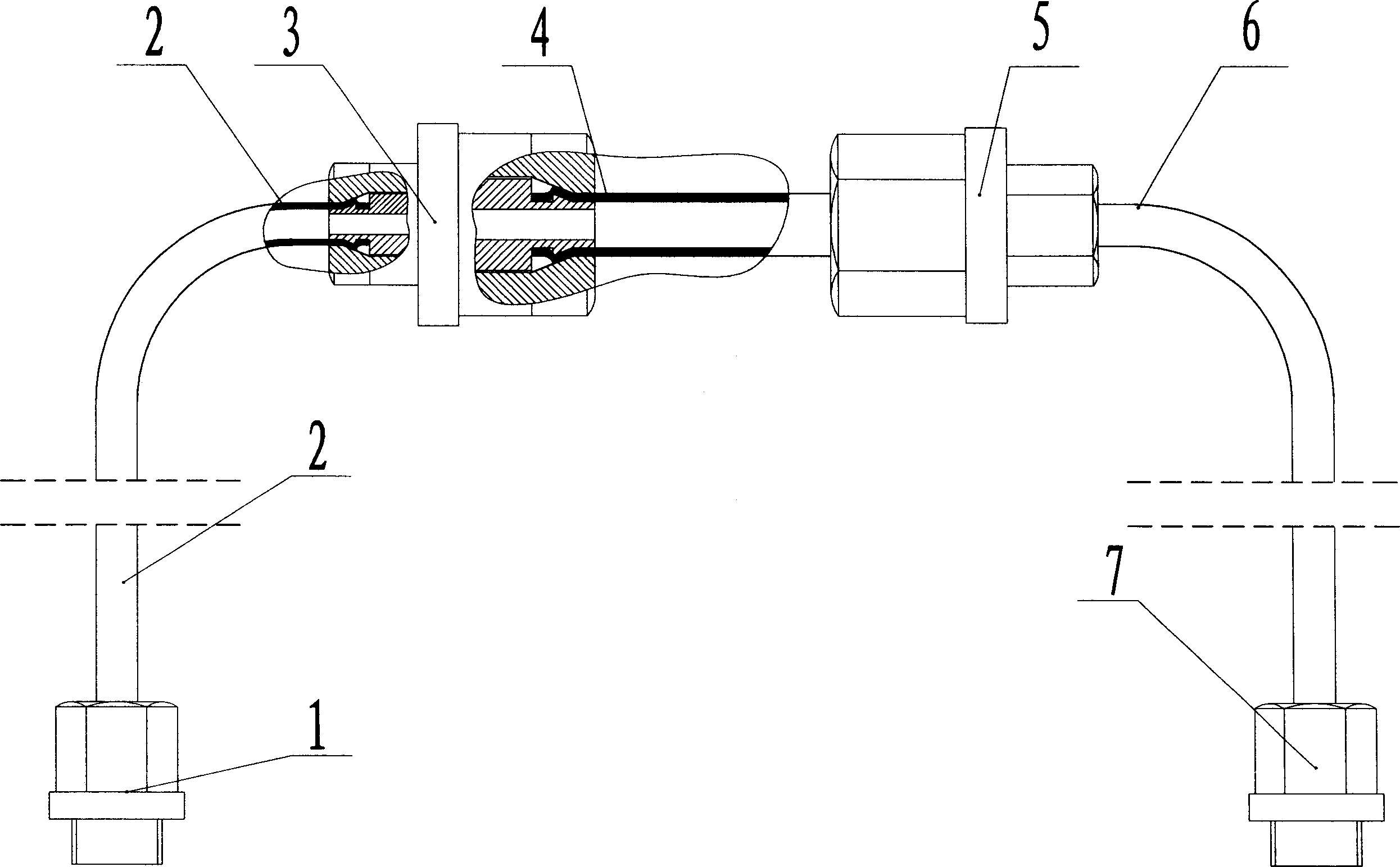

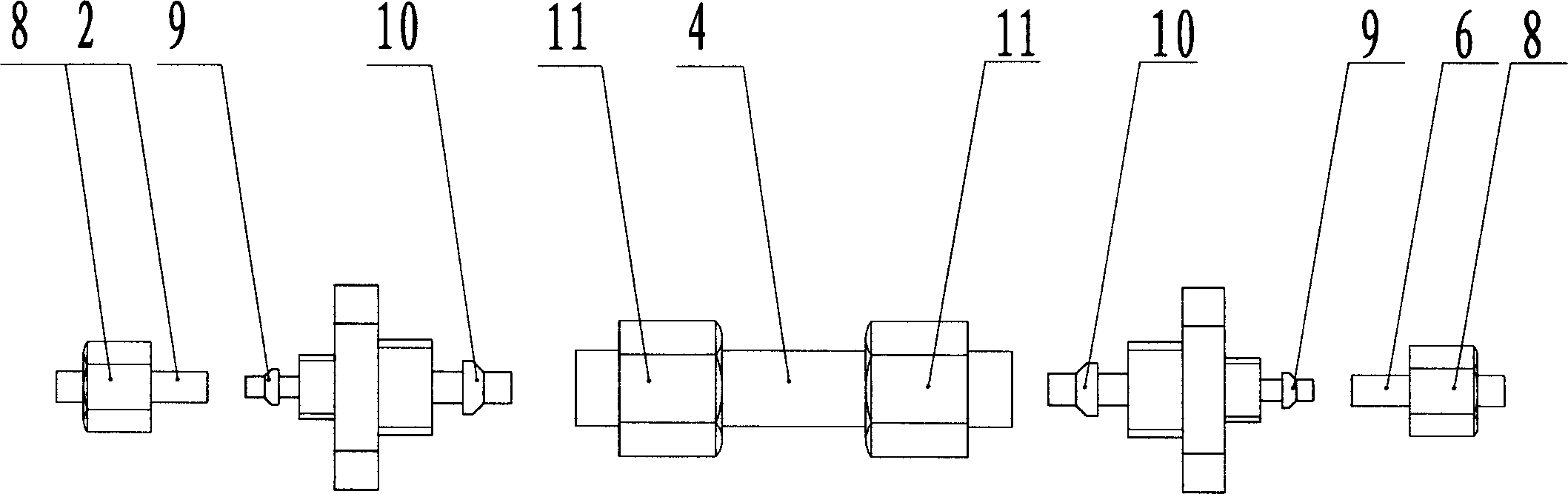

[0017] The present invention includes two quick joints 1, 7 with thin hoses 2, 6, which are characterized in that they are also connected with a pair of variable diameter quick joints 3, 5 which are sealed and socketed by thick hoses 4, and are connected by The matching large sealing nut 11 is tightly connected.

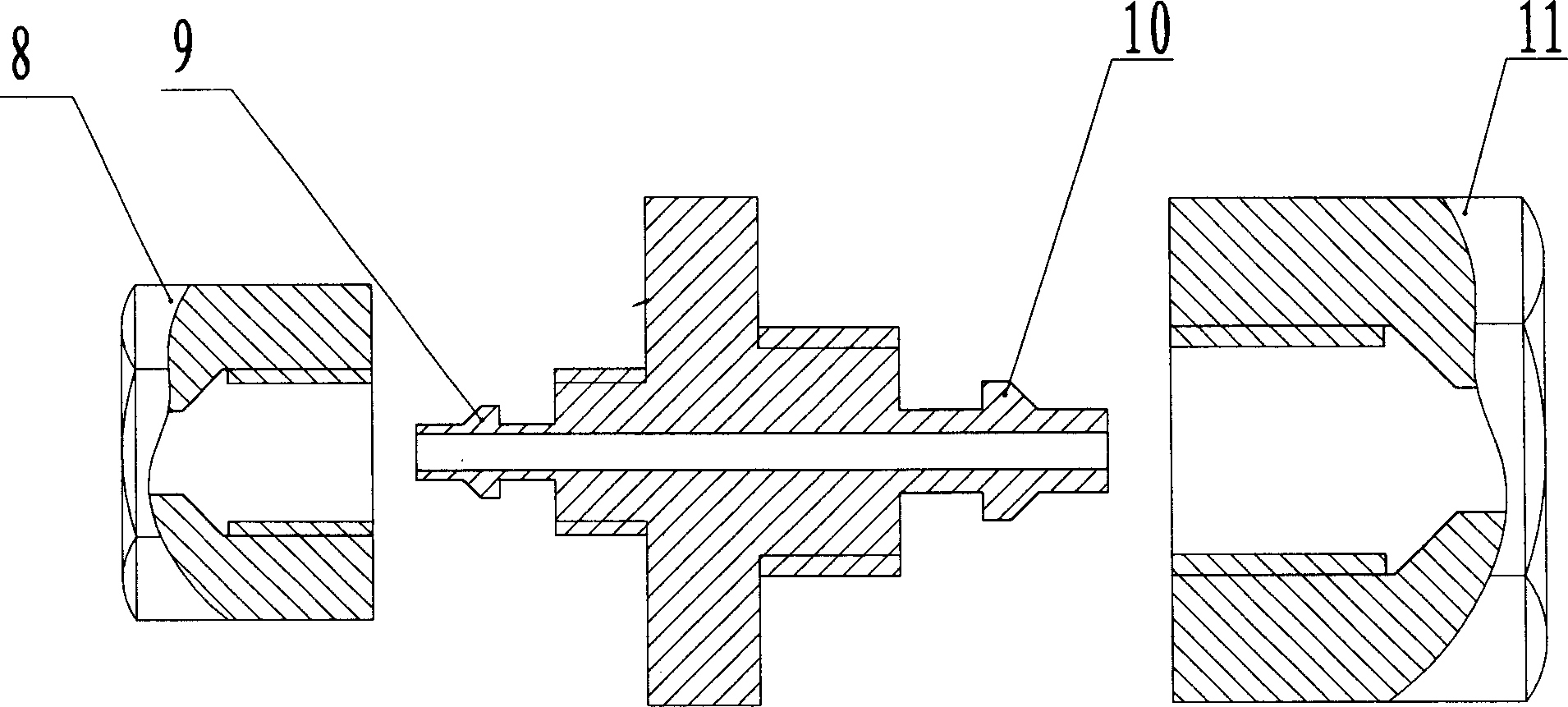

[0018] The structure of the above-mentioned variable-diameter quick joint 3 and the variable-diameter quick joint 5 is the same. The structure of the above-mentioned variable-diameter quick connectors 3 and 5 is similar to that of the quick connectors 1 and 7 .

[0019] The essence of the above-mentioned variable-diameter quick connectors 3 and 5 is a quick connector with a small sealing nozzle 9 and a large sealing nozzle 10 screwed with a small nut 8 and a large nut 11 at both ends respectively.

[0020] The two quick connectors 1 and 7 are respectively connected to the sealed chamber body of the existing equipment, usually connected with a thread and a sealing ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com