Bypass mixed excitation electrical motor

A technology of hybrid excitation motor and excitation winding, applied in the direction of magnetic circuit shape/style/structure, electrical components, electromechanical devices, etc., can solve the problems of irreversible demagnetization of permanent magnet materials and reduce the reliability of motors, and achieve simple and reliable control strategies High performance and wide adjustable range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

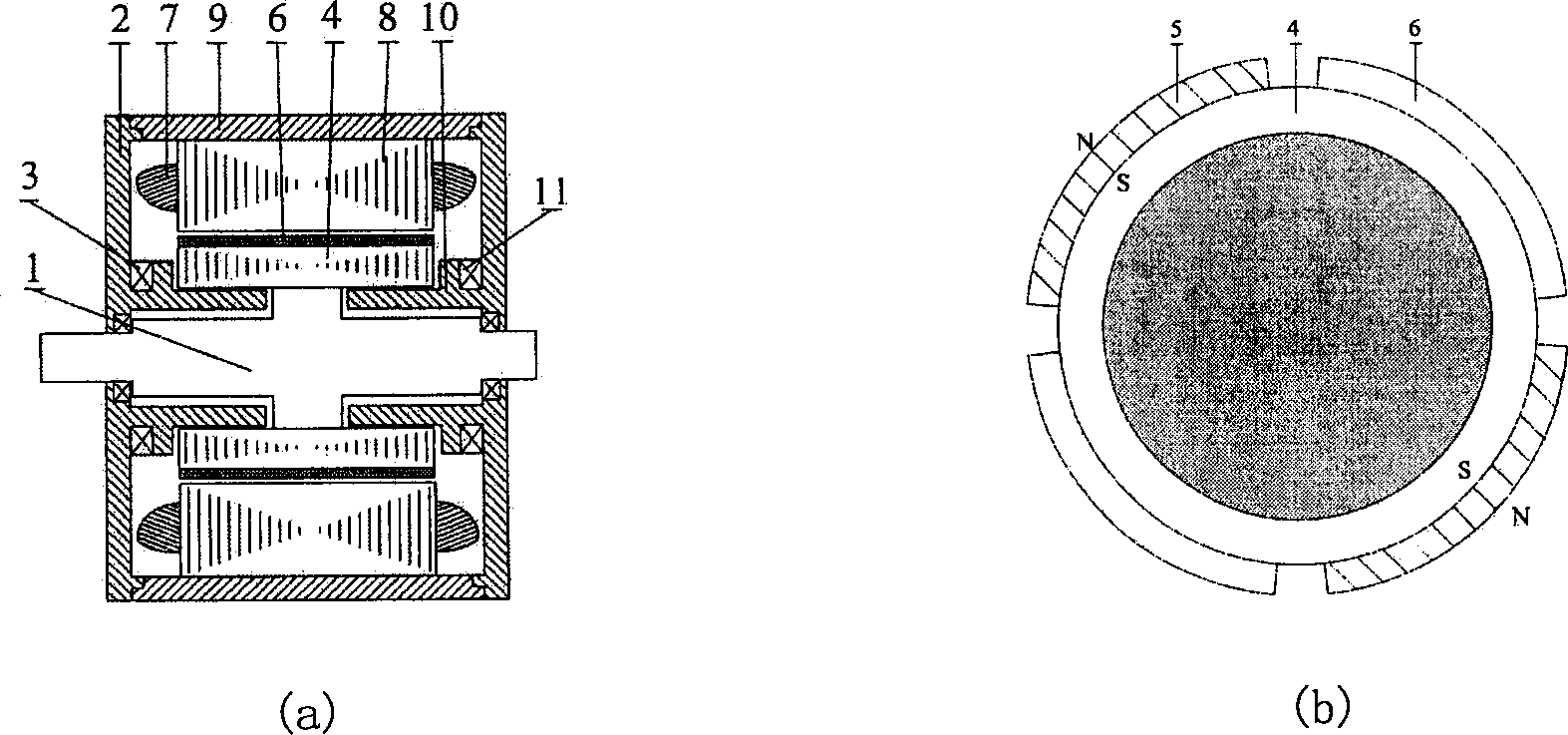

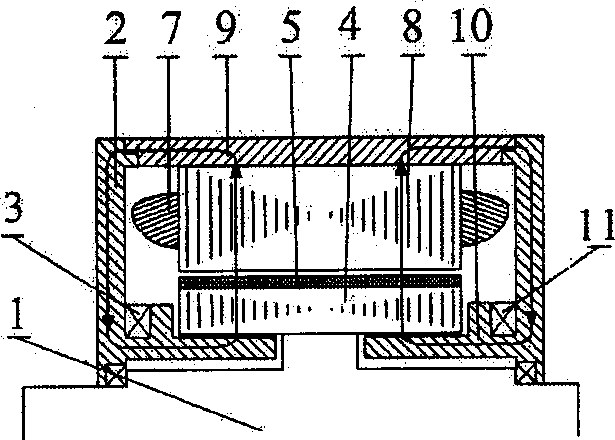

[0026] The bypass hybrid excitation motor of the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments:

[0027] 1) In order to ensure the effective control of the DC excitation magnetic field, it is necessary to ensure that the second air gap is smaller than the length of the air gap between the stator and rotor of the motor in the manufacture of the motor, and the smaller the better. In the embodiment of the present invention: the inner side of the end cover 2 is processed into a shape with a two-way side wall flange 10, and one side of the flange 10 just matches the inner circle of the rotor to ensure that the second air gap is as small as possible, even if the motor has a longitudinal direction. The other side of the flange 10 is used to fix the DC field windings 3 and 11. For details, see figure 1 .

[0028] 2) Since the second air gap is smaller than the length of the air gap between the stator and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com