Shape memory alloy driven miniature guide device for interventional blood vessel operation

A memory alloy, micro-device technology, applied in the field of shape memory alloys, can solve problems such as effectiveness and safety limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

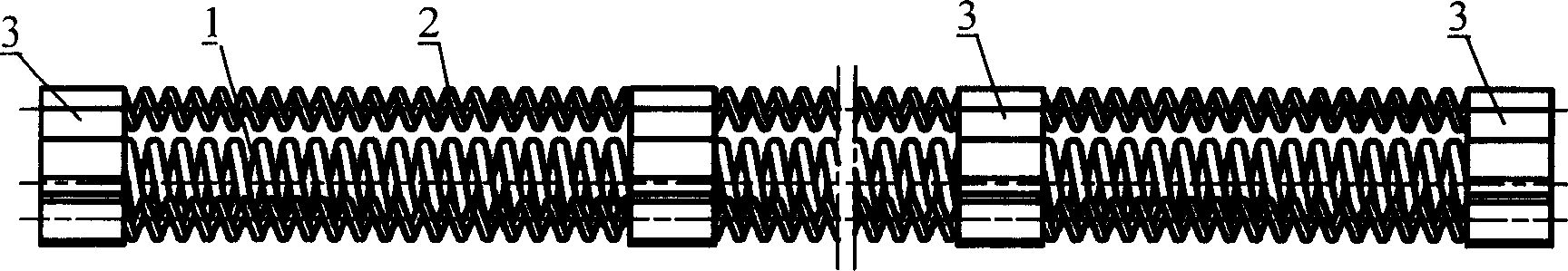

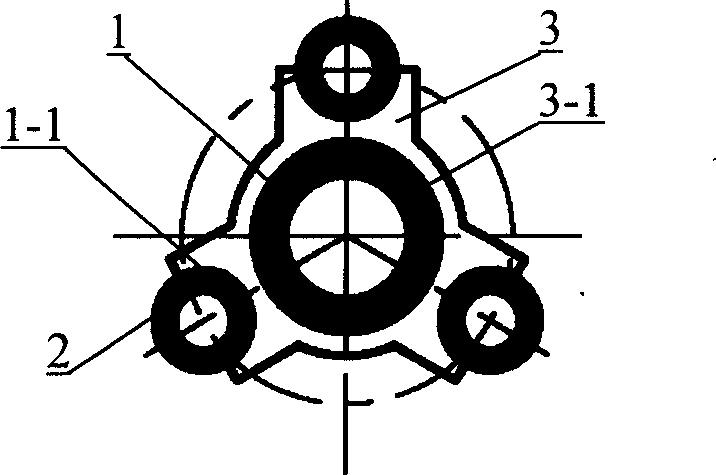

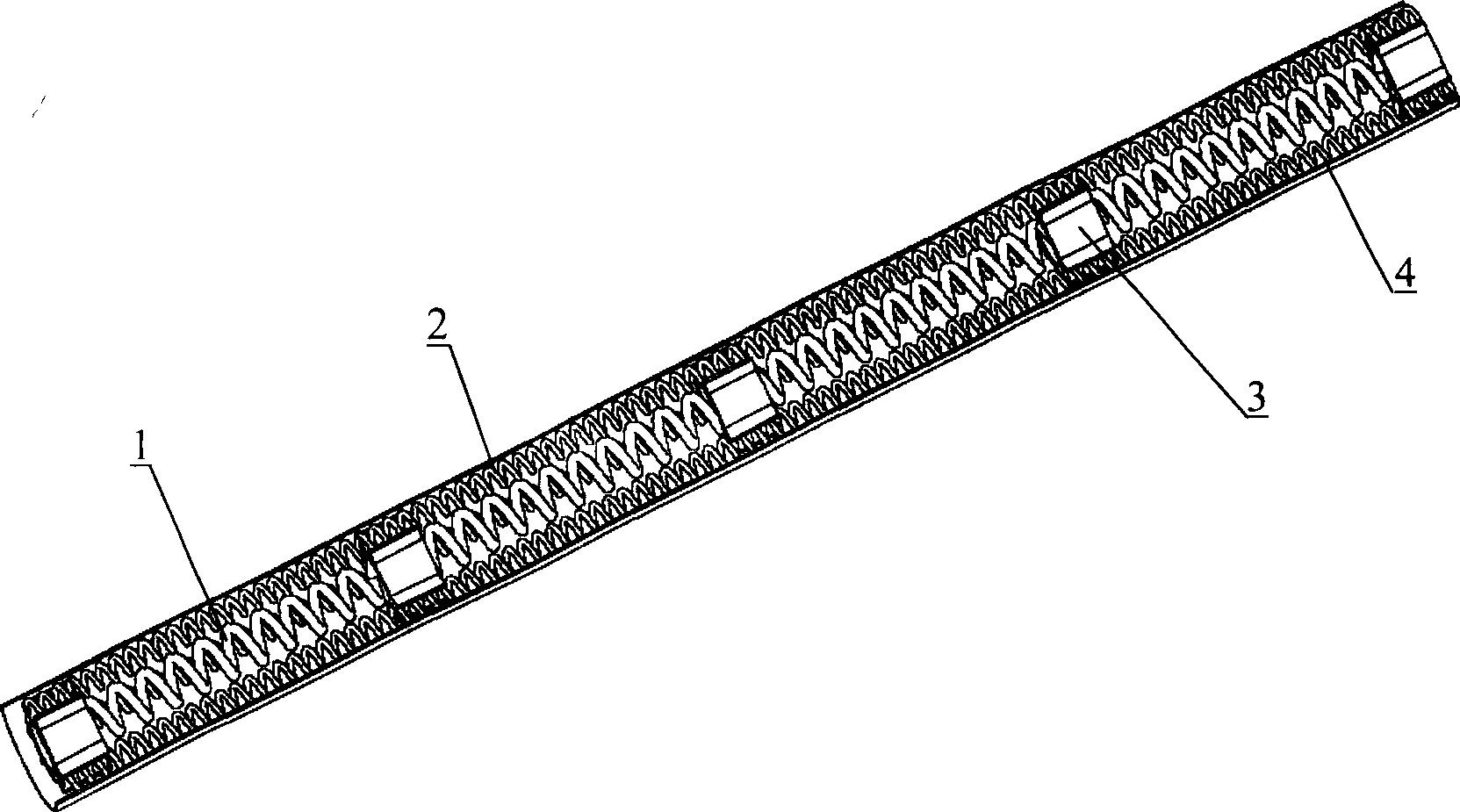

[0005] Specific implementation mode one: (see Figure 1-Figure 5 ) This embodiment consists of a bias spring 1, three shape memory alloy (SMA) springs 2 and two connectors 3, the bias spring 1 is a compression spring, the connector 3 has a central through hole 3-1, and the bias The spring 1 passes through the central through hole 3-1 on the two connectors 3 and is fixedly connected with the central through hole 3-1. The three shape memory alloy springs 2 are evenly distributed on the outside of the bias spring 1 and are respectively connected with the The outer surface of part 3 is fixedly connected as a whole. Since the tensile strength of the NiTi alloy is above 1000Mpa, the elongation is above 20%, and the fatigue life reaches 10 7 Second, the damping characteristic is 10 times higher than that of ordinary springs, and its corrosion resistance is better than the best medical stainless steel at present. The bias spring described in this embodiment can be selected as a shape...

specific Embodiment approach 2

[0006] Specific implementation mode two: (see Figure 1-Figure 5 ) The difference between this embodiment and the specific embodiment 1 is that the connection between the connecting member 3 and the bias spring 1 is a concave arc surface 1-1, and the shape and size of the concave arc surface 1-1 are the same as The outer diameter of the bias spring 1 matches. Other compositions and connections are the same as in the first embodiment. Because the shape and size of the inner concave arc surface 1-1 match the outer diameter of the bias spring 1, the contact area between the connector 3 and the bias spring 1 is the largest, and when the SMA spring 2 undergoes a phase change, the present invention is guaranteed Action reliability.

specific Embodiment approach 3

[0007] Specific implementation mode three: (see Figure 1-Figure 5 ) The difference between this embodiment and the first or second embodiment is that the connector 3 is made of an insulating material or a conductive material whose outer surface is coated with an insulating film. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2. This embodiment avoids the problem that the performance of the whole micro-device is affected by the conduction of electricity between the SMA springs or between the SMA spring and the bias spring.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com