Plastic bottle cap printing machine

A technology for printing machines and bottle caps, applied in printing machines, rotary printing machines, printing, etc., can solve the problems of high price, slow speed, and poor effect, and achieve the effect of convenient operation, simple structure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

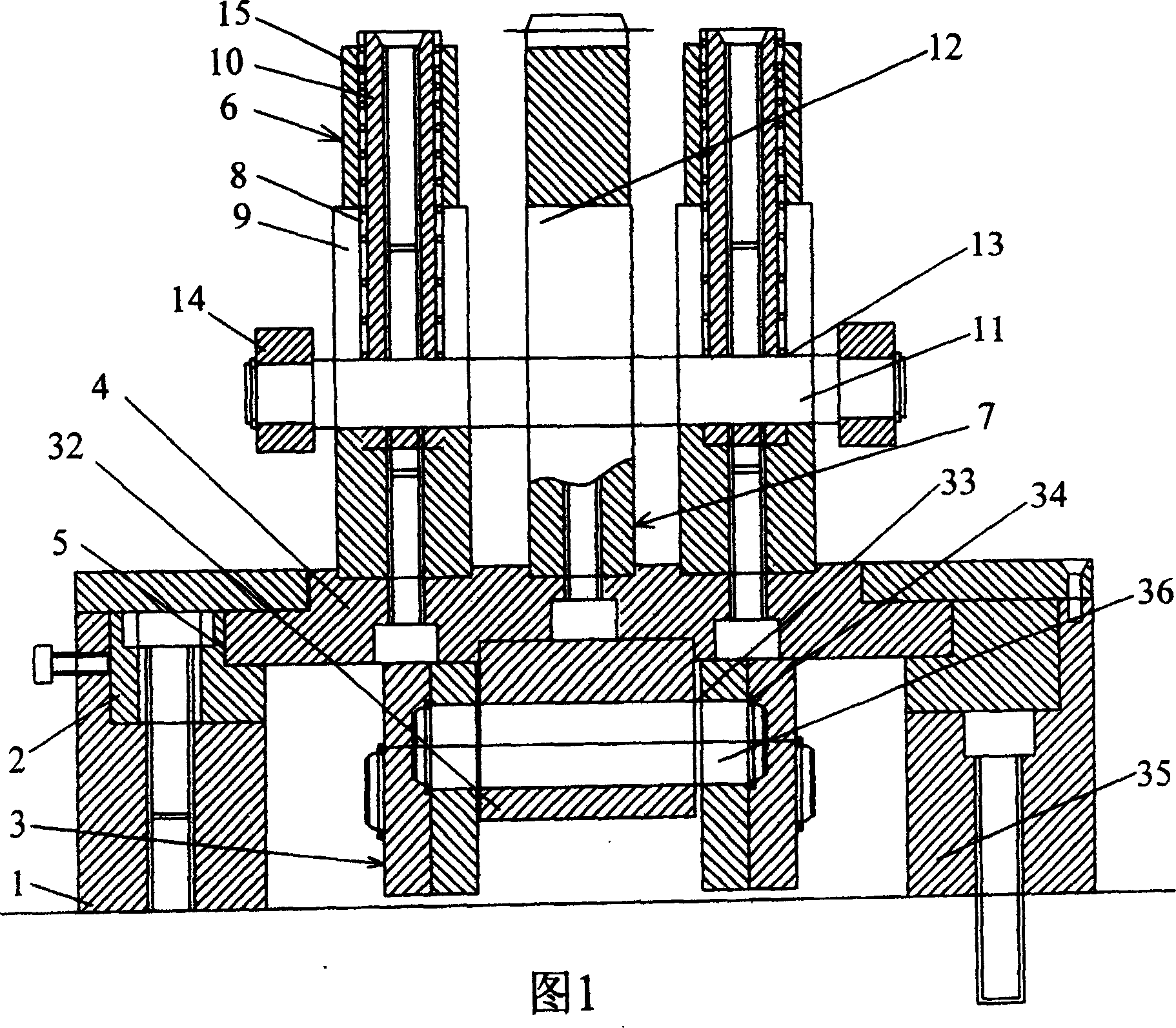

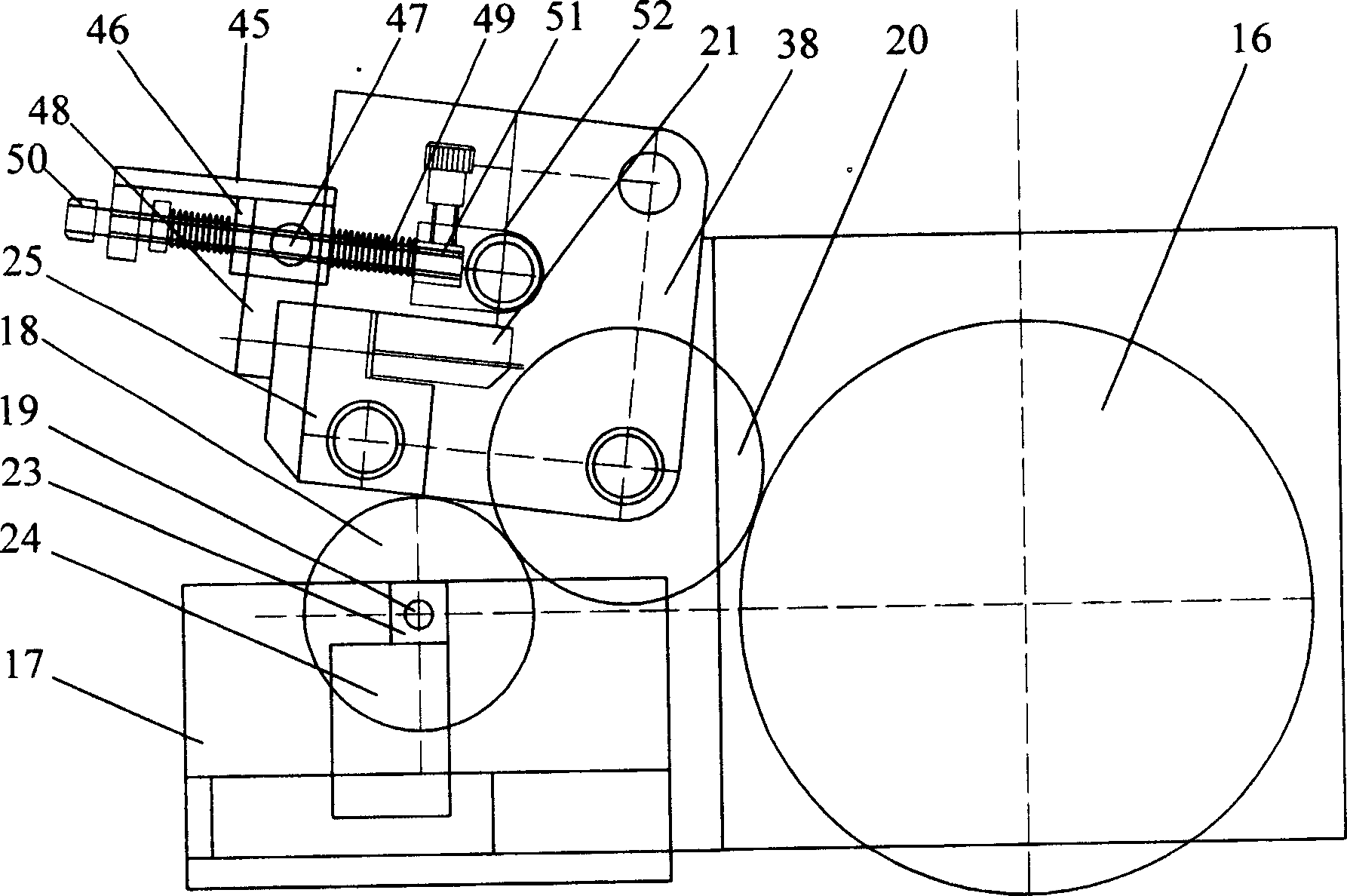

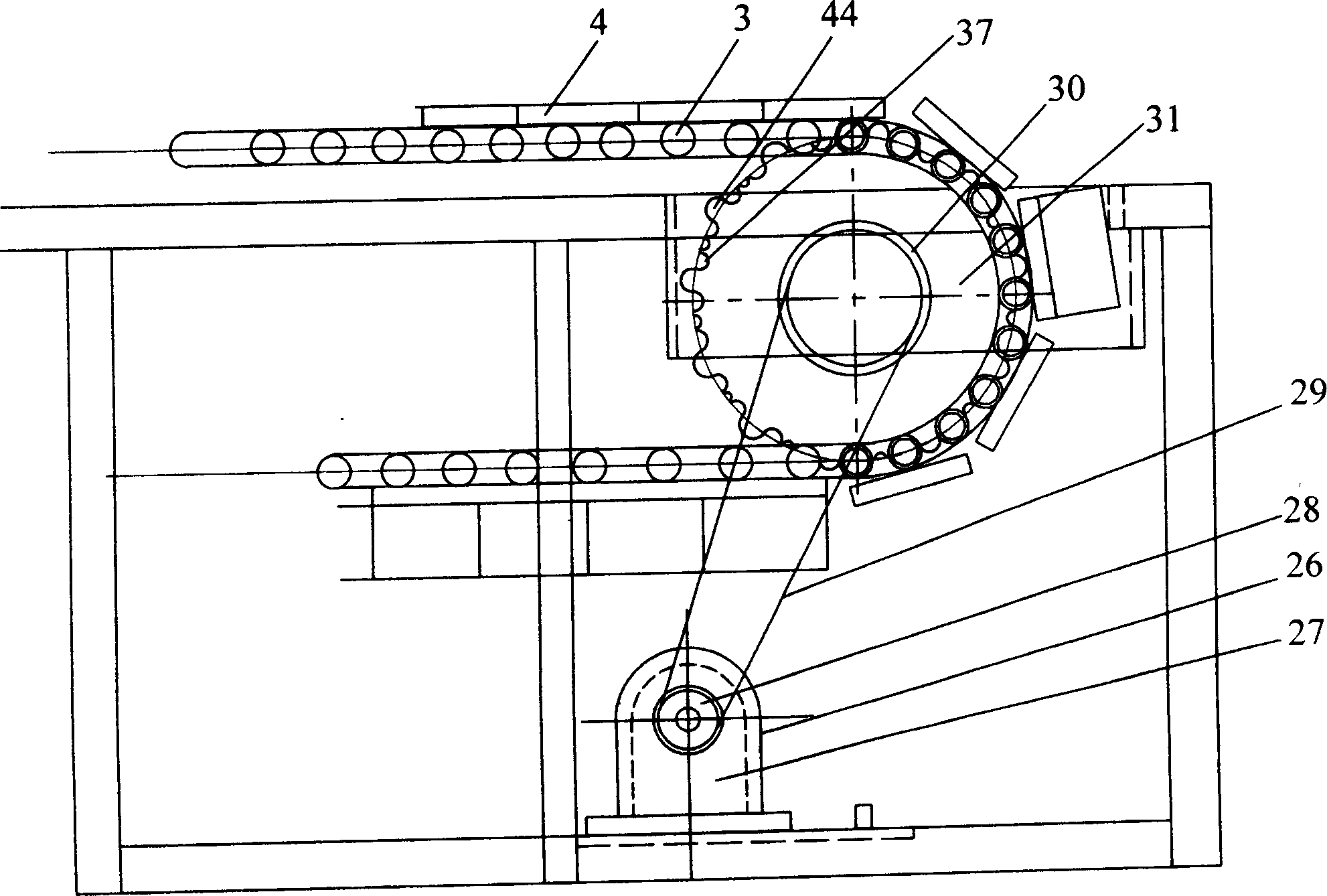

[0020] Plastic bottle cap printing machine mainly includes bottle cap feeding mechanism, bottle cap conveying mechanism, positioning mechanism, cap unloading mechanism, 4 ink printing mechanisms and transmission mechanism, among which, the bottle cap conveying mechanism includes guide rail bracket 1, guide rail 2, chain 3 and a plurality of pallets 4 arranged on the closed chain 3 and arranged in sequence along the closed chain. The guide rail 2 is arranged on the upper end of the guide rail support 1, and the left and right sides of a plurality of supporting plates 4 are respectively arranged in the rail groove 5 of the guide rail 2, and can move back and forth in the rail groove 5; the positioning mechanism includes two rows of positioning fixtures 6, Two rows of positioning fixtures 6 are divided into multiple components and arranged on a plurality of pallets 4 . Two rows of positioning jigs 6 on each pallet 4 correspond one-to-one. Each group of positioning fixtures 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com