Non-reciprocal circuit element

A circuit element and electrode technology, applied in the field of non-reciprocal circuit elements, can solve the problems of affecting productivity, disadvantageous thinning, and increasing cost, and achieve the effect of good productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

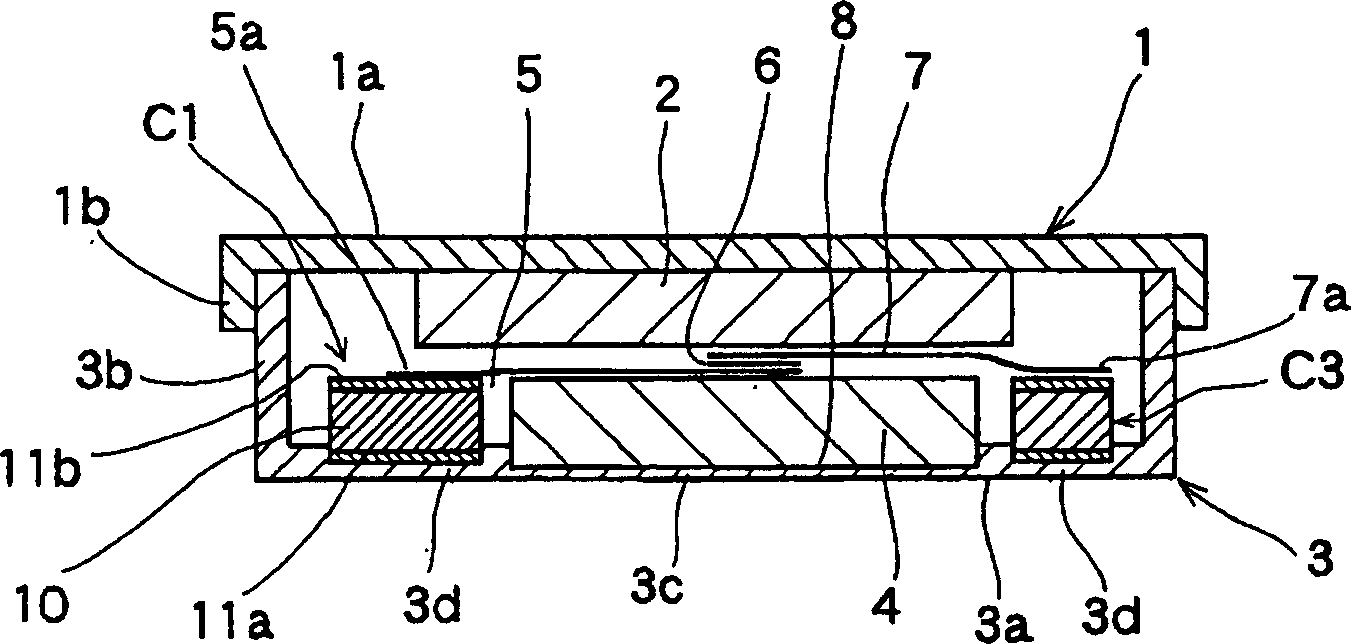

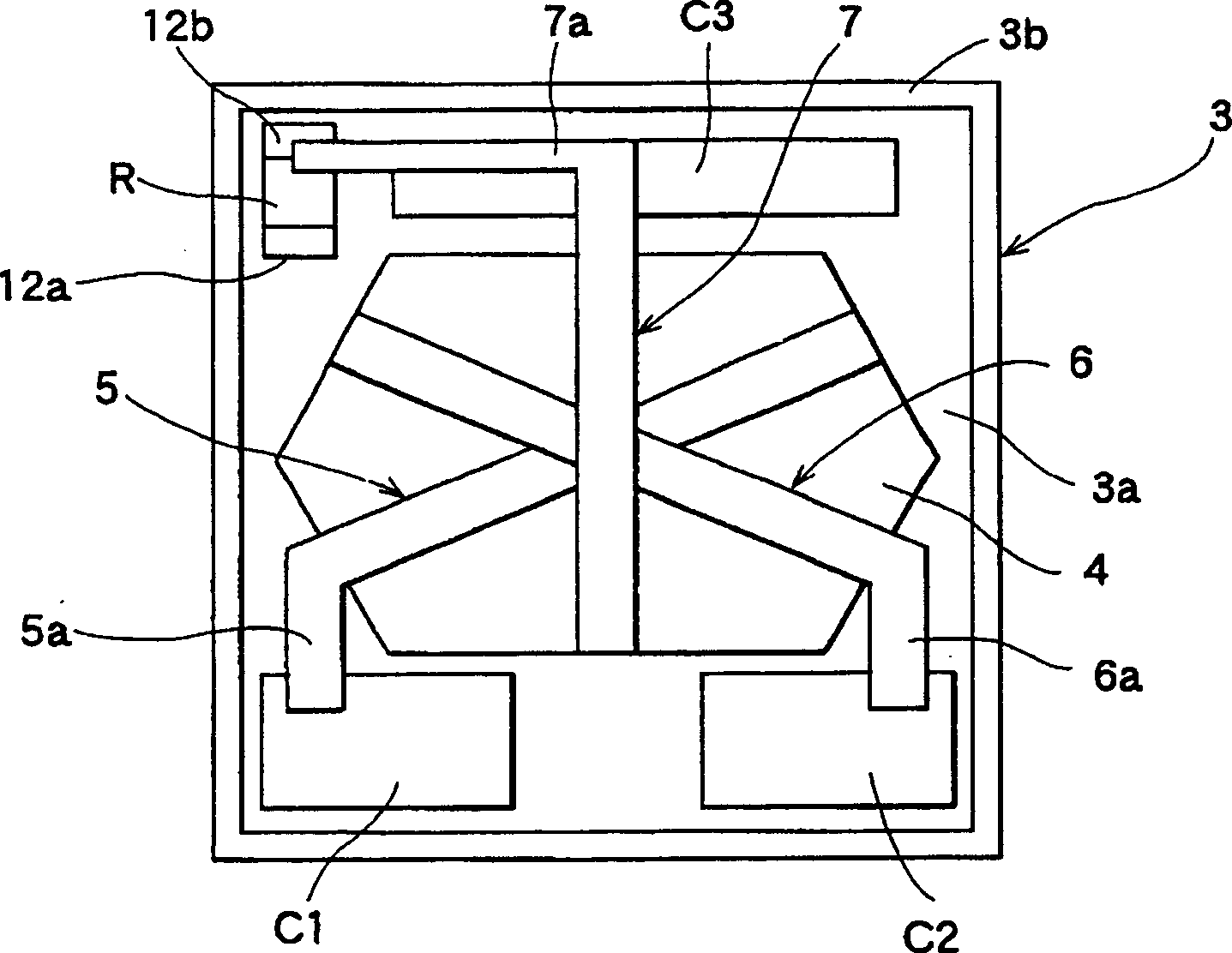

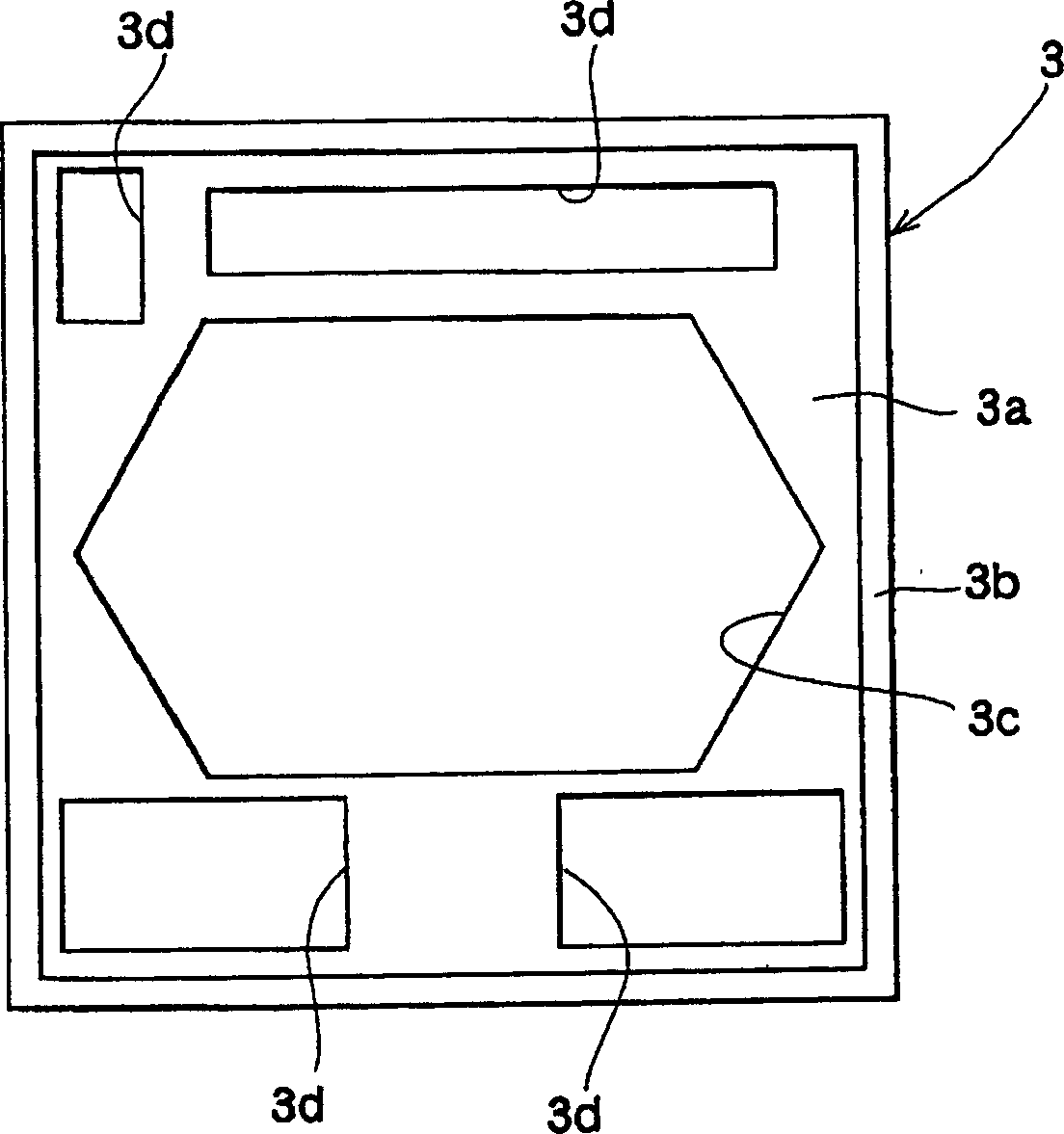

[0022] Referring to the accompanying drawings of the non-reciprocal circuit element of the present invention, there are Figure 1 ~ Figure 4 . in: figure 1 It is a sectional view of the essential parts involved in the non-reciprocal circuit element of the present invention; figure 2 It is a top view showing the non-reciprocal circuit element of the present invention after removing the first yoke and the magnet; image 3 It is a plan view showing the non-reciprocal circuit element of the present invention after removing the second yoke; Figure 4 It is an expanded view of the central conductor involved in the non-reciprocal circuit element of the present invention.

[0023] Below, according to Figure 1 ~ Figure 4 , telling the structure of applying the non-reciprocal circuit element of the present invention in the isolator. The first yoke 1 made of a U-shaped or box-shaped magnetic plate (iron plate, etc.) has a square (rectangular) upper plate 1a and side plates 1b ben...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com