Spliced heat-conductive floor board

A technology for heat-conducting floors and boards, applied in heating methods, household heating, heating systems, etc., can solve the problems of easy deformation of the floor, difficult to achieve the effect of heat conduction and heat preservation, warping, etc. The effect of not easy to deform and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

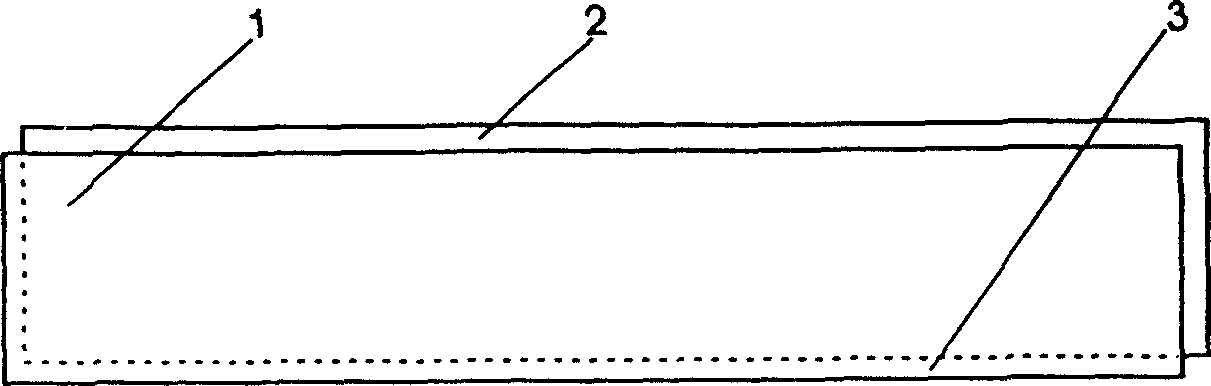

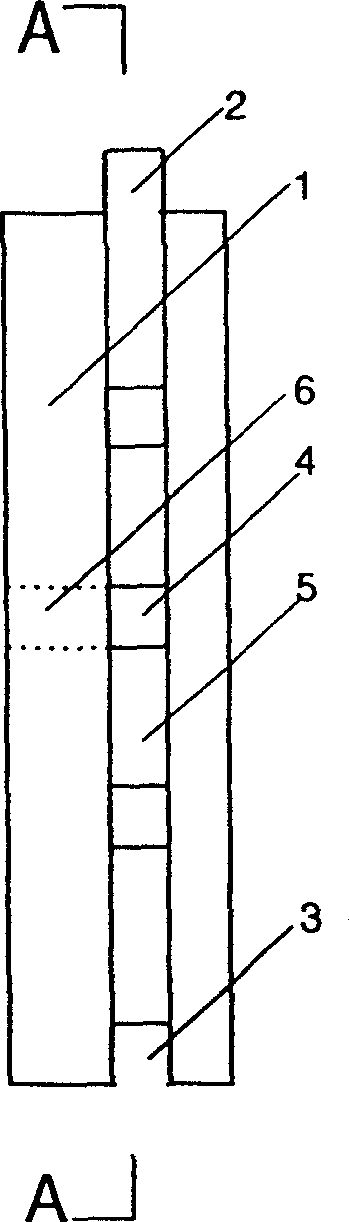

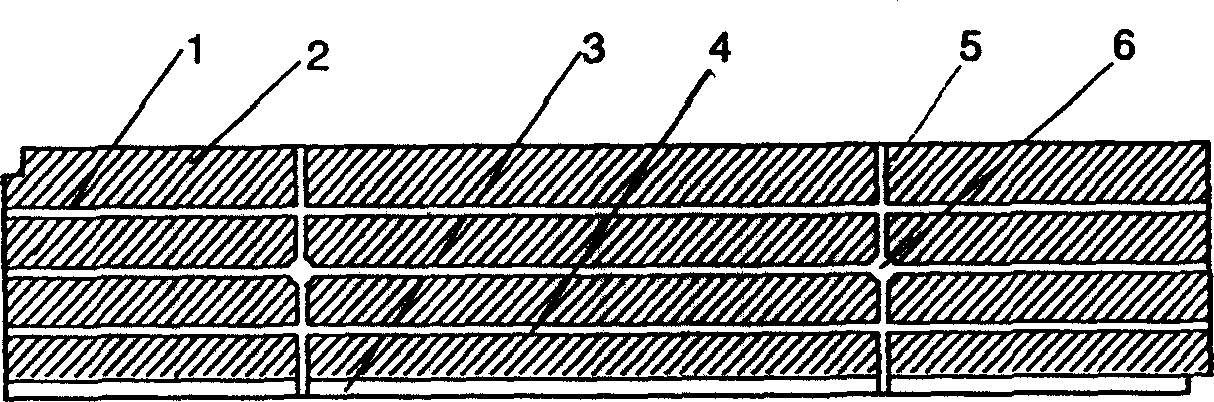

[0018] Example: according to Figure 1 to Figure 5 As for the assembled heat conduction floor of the present invention with the above-mentioned structure, the length of the floor is selected in the range of 300×50~1000×300mm, and the sizes of other components are matched with it according to the ratio shown in the figure. see Figure 1~5 , take a floor blank with a thickness of 14 mm as the board body 1, and planer planer longitudinal groove pipes 4 and transverse groove pipes 5 on the board surface of the board body 1. The number of the longitudinal grooved tubes 4 is more than 3 (including 3), and the number of the transverse grooved tubes 5 is more than 2 (including 2). Then drill 2 perforated hole pipes as guide pipe 6 on the grooved pipe. Then on the four sides of the board body 1, as in the making of traditional assembled floors, the tenon 2 is planed out on the adjacent two sides, and the tenon groove 3 is planed out on the other adjacent two sides. The processed blan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com