Lens driving device

A lens driving device and lens driving technology, applied in installation, optics, instruments, etc., can solve the problems of increasing driving loss, slowing lens moving speed, slow response, etc., reducing driving loss, improving response performance, and satisfying The effect of fine-tuning the action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

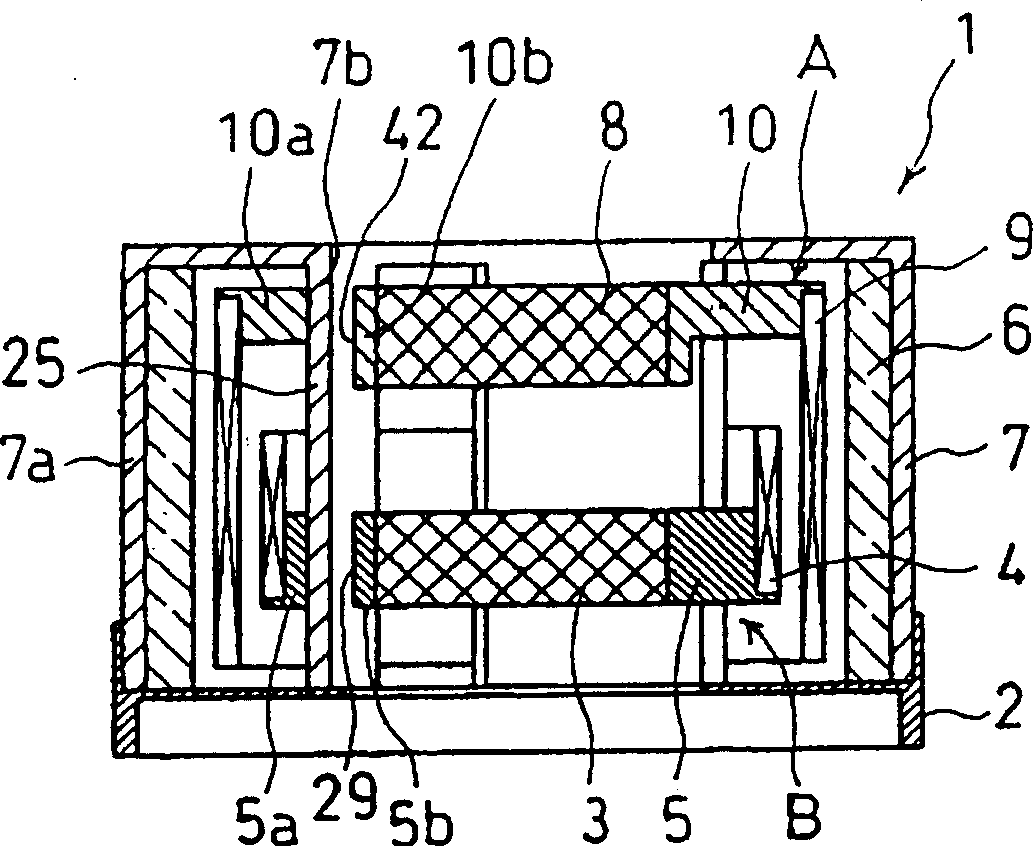

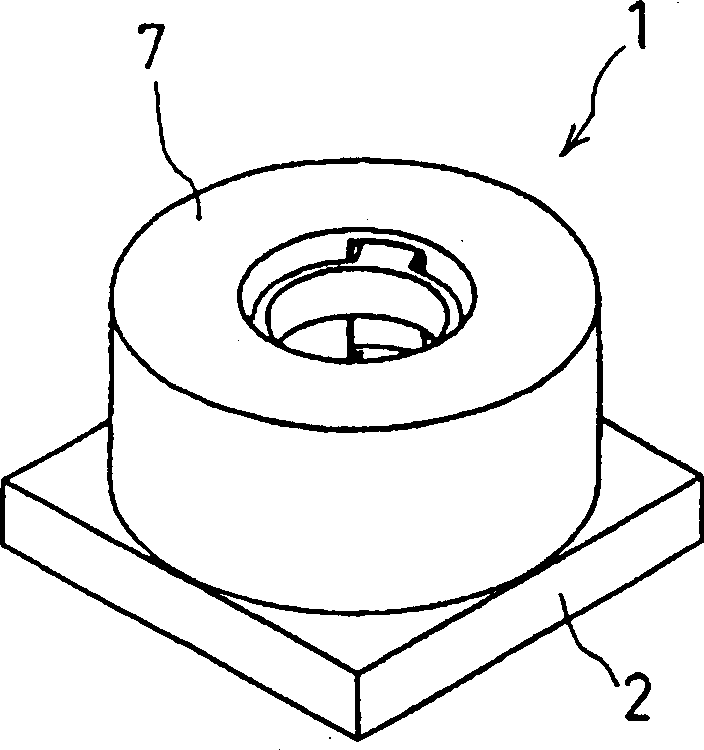

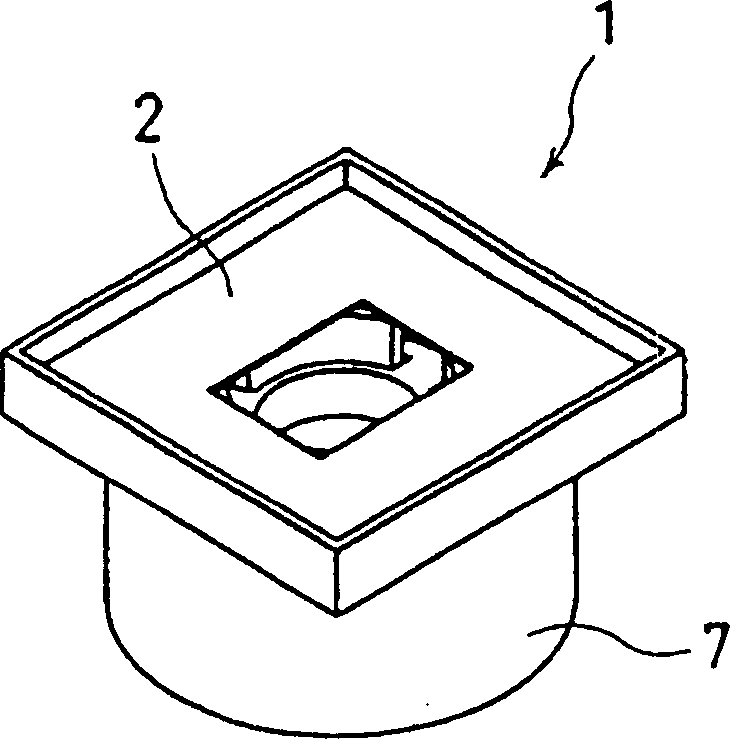

[0032] See Figure 1 to Figure 5 As shown, they are schematic structural diagrams of the first embodiment of the lens driving device of the present invention. The lens driving device 1 of the present invention is a lens driving device that can be assembled in an auto-focus camera in a mobile phone. The lens driving device 1 of the present invention consists of a base 2, a ring mouth 7 arranged on the base 2, a magnet 6 located in the ring mouth 7, and a first lens driving part A and a second lens driving part A which are jointly arranged in the magnet 6 and the ring mouth 7. Composed of lens driving part B. The first lens driving part A is arranged inside the magnet 6; the second lens driving part B is concentrically arranged inside the first lens driving part A, and they share the same ring mouth 7 and the magnet 6, thereby reducing the size of the lens driving device The overall outer diameter of the lens drive device can be miniaturized.

[0033] A circular groove 21 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com