Quality management system of print substrate

A printed substrate, quality management technology, applied in measuring devices, material analysis through optical means, instruments, etc., can solve problems such as bad confirmation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

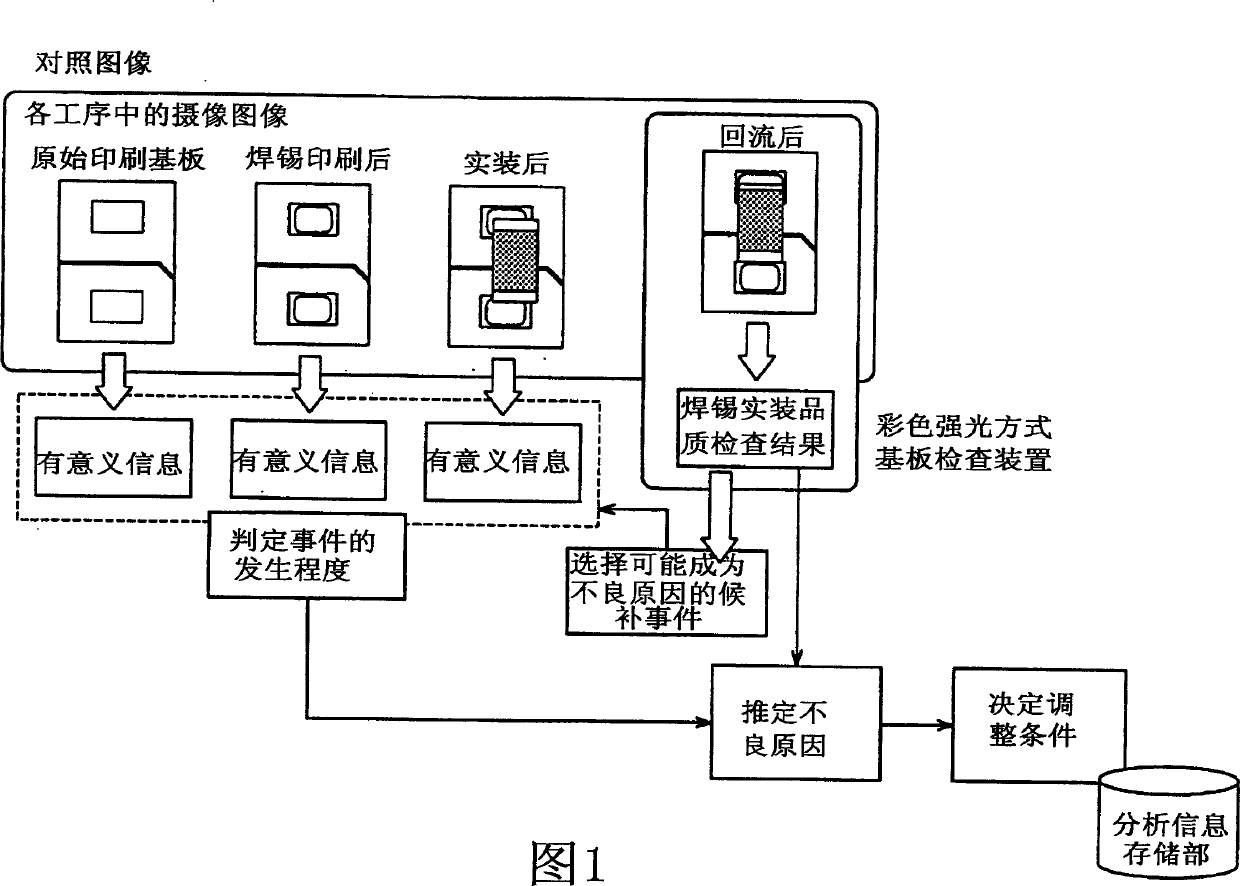

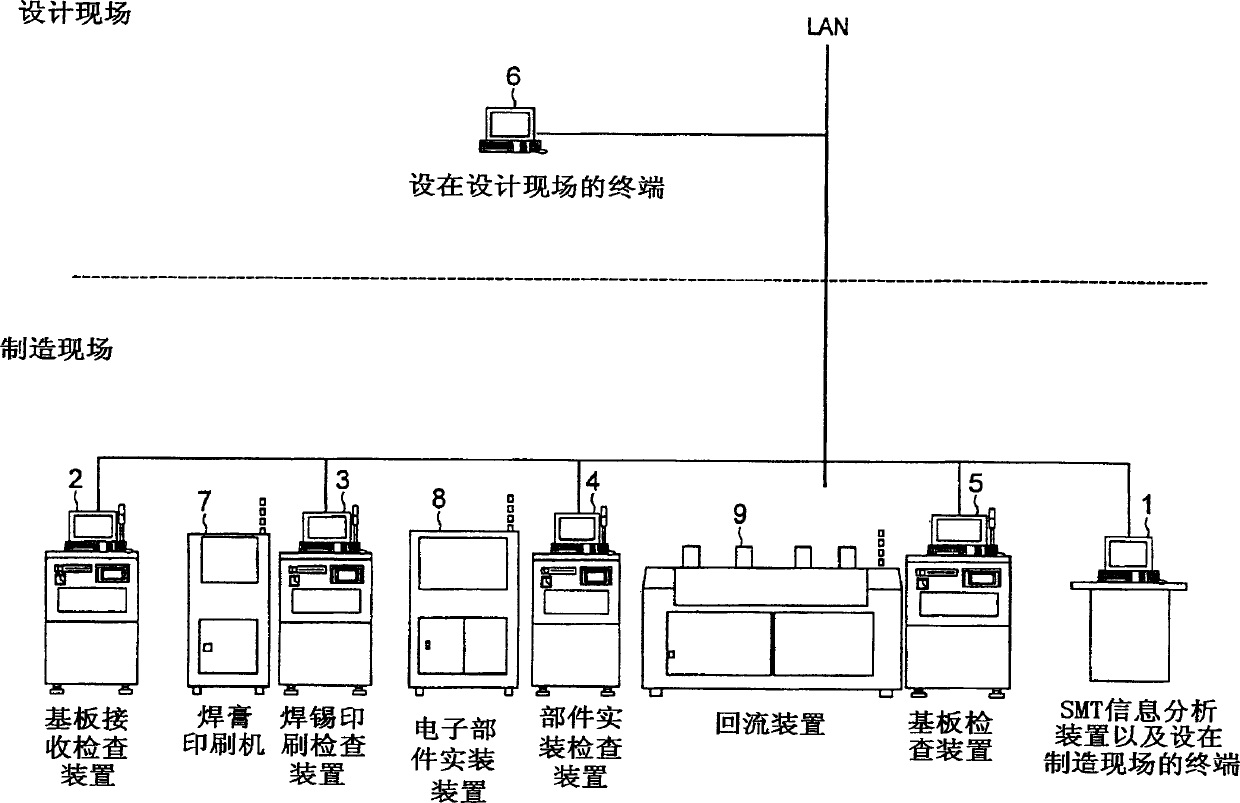

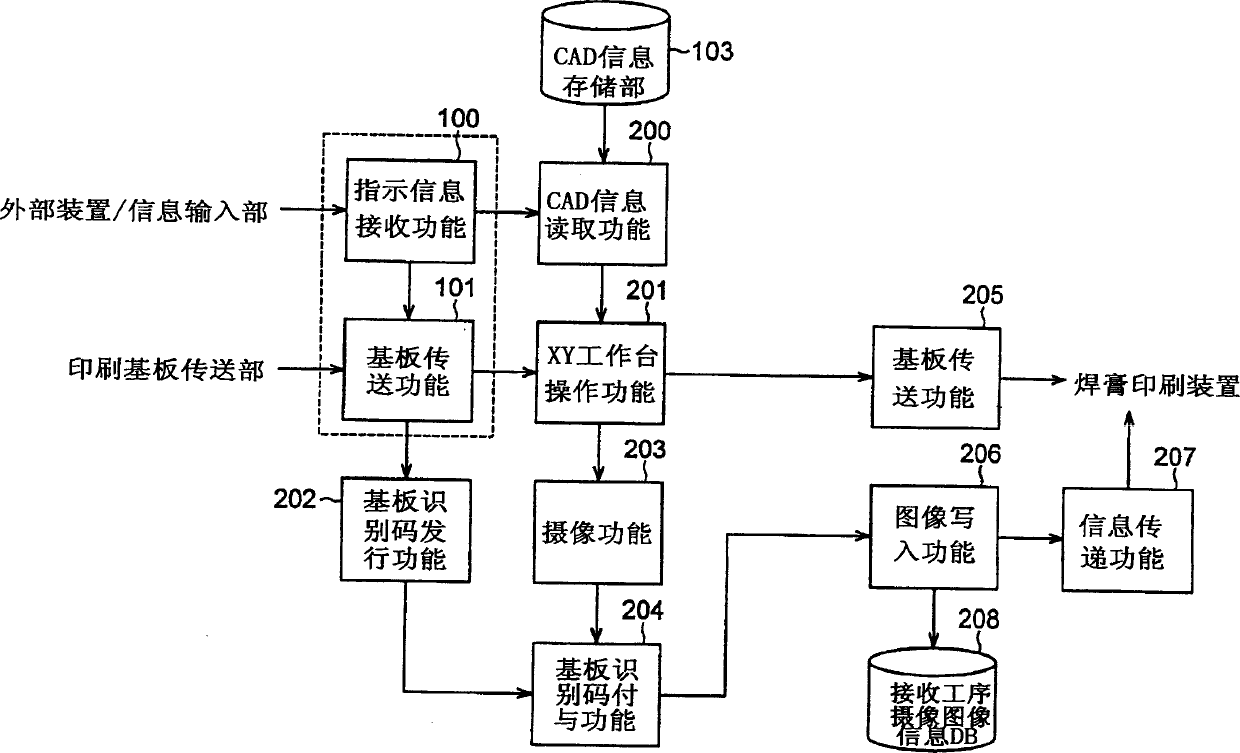

[0111] First, an outline of processing in the quality control system according to the first embodiment of the present invention will be described with reference to FIG. 1 . In the present embodiment, the quality control at the time of production commissioning / mass production trial production is targeted.

[0112] In the production commissioning / mass production trial production before the full-scale production, generally speaking, it is necessary to repeat the trial production and the adjustment of the manufacturing conditions (hereinafter referred to as "SMT conditions" as the meaning of the manufacturing conditions related to surface mounting), Quality improvement in the field. The quality control system of this embodiment assists on-site problem solving by estimating the cause of the failure and determining its countermeasures when there is a problem with solder mounting quality.

[0113] As shown in FIG. 1 , in this system, images are taken of each printed board after rece...

no. 2 approach

[0228] FIG. 30 shows an outline of processing in the quality control system according to the second embodiment of the present invention. Compared with the first embodiment, the quality control system of this embodiment is the same in that it performs the estimation of the cause of the failure and the determination of the SMT conditions that need to be adjusted, and the difference lies in the subsequent processing (adjustment condition analysis) that assists the improvement of the condition value. deal with).

[0229] Specifically, after determining the SMT conditions requiring adjustment in the same manner as in the first embodiment, the quality control system determines a plurality of condition values with slightly different values for the SMT conditions. These conditional values are used for tuning tests. The user adjusts the condition value for the test according to these, slightly changes the SMT condition, and repeats the trial production. The quality control syst...

no. 3 approach

[0255] Currently, Japan's manufacturing industry is groping for ways to survive as a production location. The environment surrounding the domestic manufacturing industry is becoming more and more severe due to the shortening of the service life of products, the reduction of shipments, and the transfer of production sites to China. Then, in order to survive as a production place, Japan began to challenge the new production method (required simultaneous production) that needs to be produced simultaneously. Need-synchronized production refers to a production method that is synchronized with demand and quality, and is conducive to the production of small quantities and multiple varieties.

[0256] In this synchronous production, production and quality need to be controlled at the same time, and production and quality must be consistent in time. This is because, in the case of the existing mass production method, how many defects are planned out of the 10,000 manufactured, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com