Manufacture of toroidal transformers

A technology of toroidal transformers and manufacturing methods, applied in transformers, inductance/transformer/magnet manufacturing, fixed transformers, etc., can solve labor-intensive, unsuitable for large-scale production of small-scale transformer automation, time-consuming problems, etc., to reduce the relative size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will now be further described, by way of example and for purposes of illustration only, with reference to the accompanying drawings.

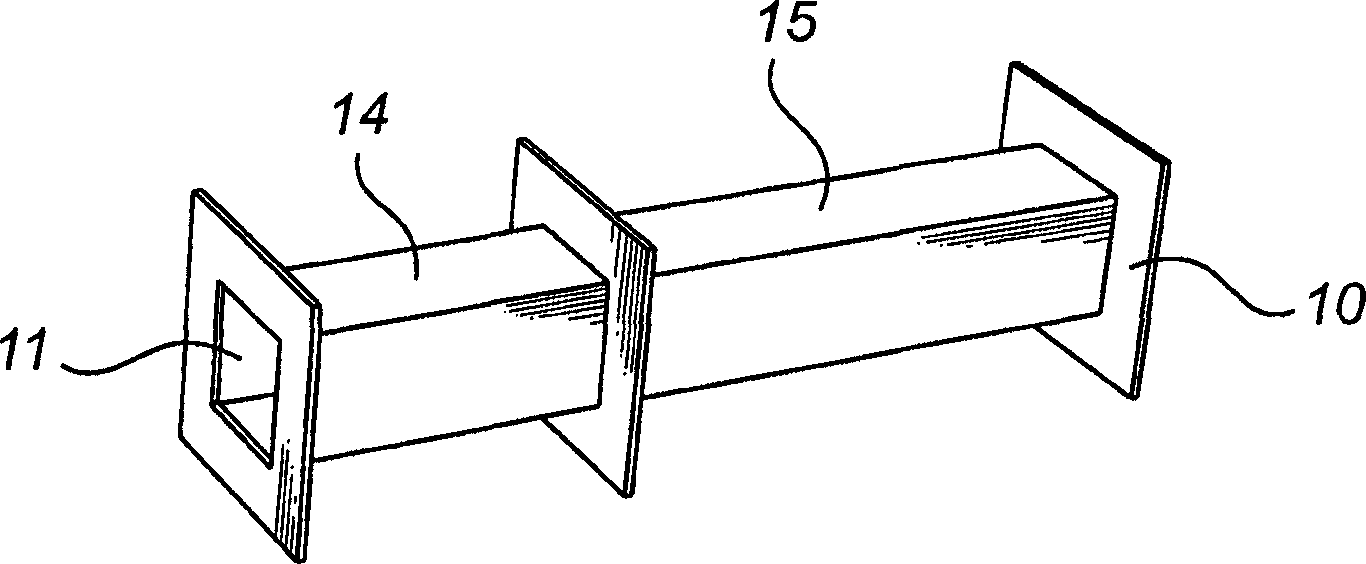

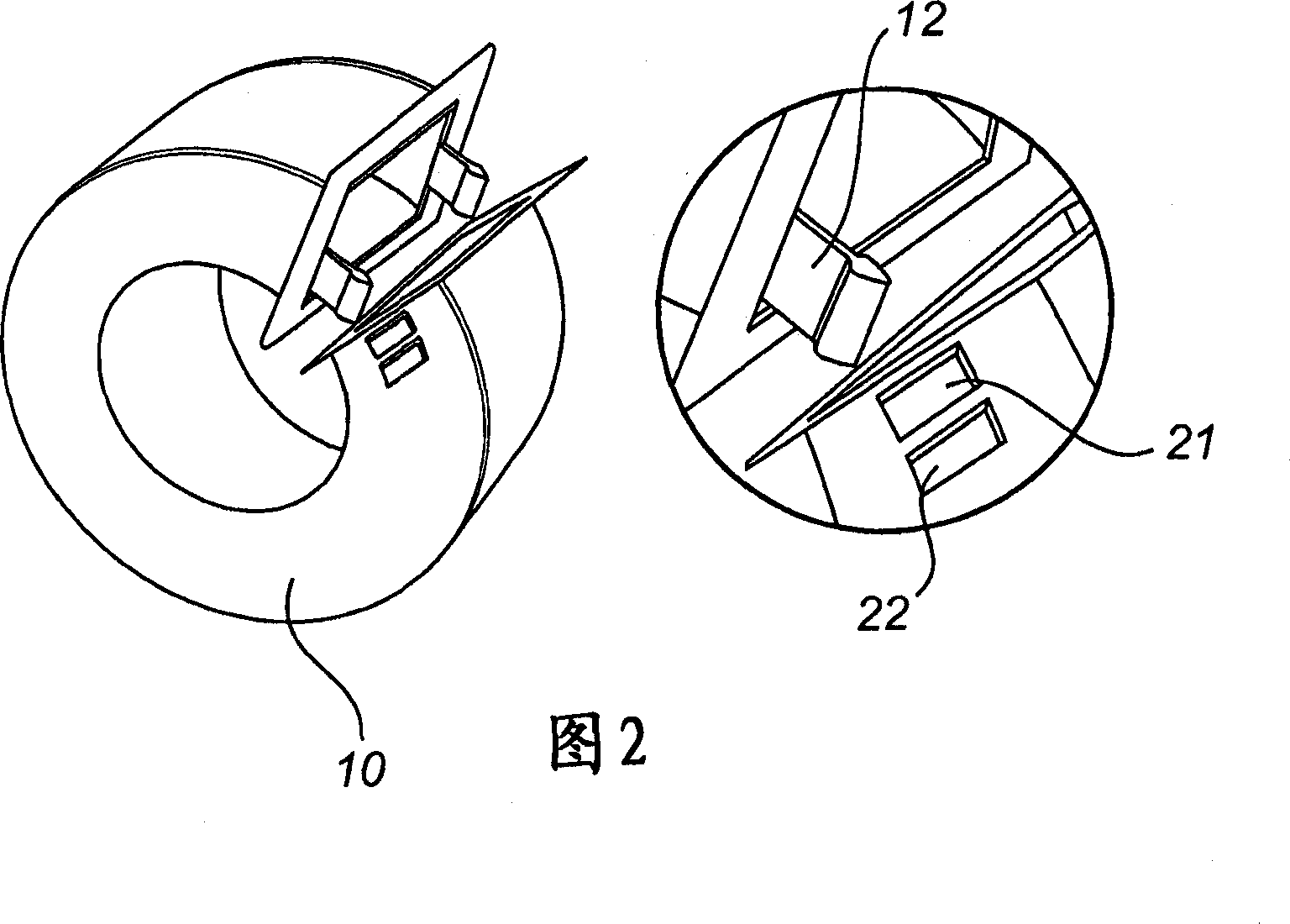

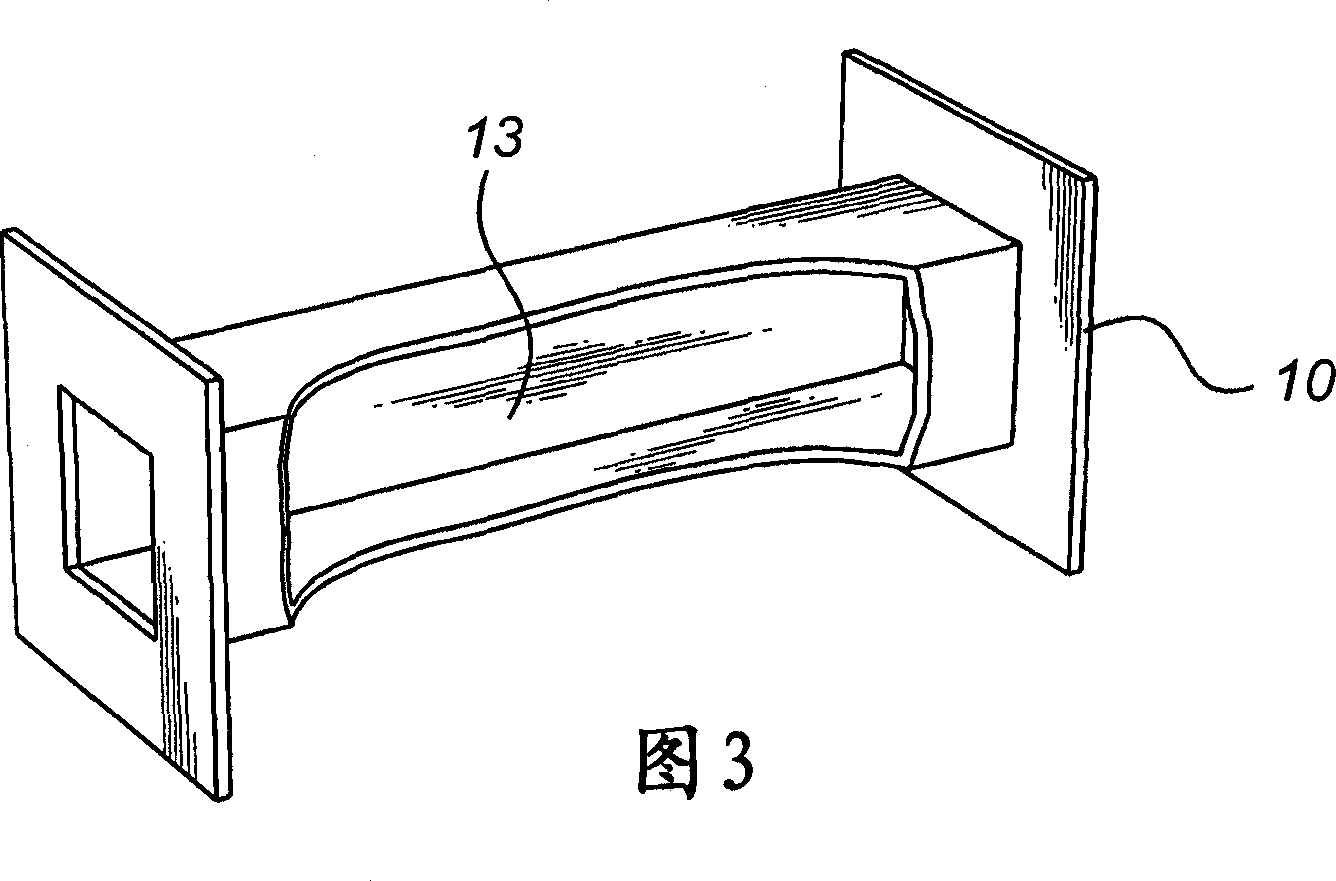

[0044] figure 1 is a perspective view showing an embodiment of a bobbin 10 according to the invention for the manufacture of a toroidal transformer.

[0045] The spool 10 consists essentially of an elongated tube of flexible material. Said flexible material can be, for example, plastic material or rubber. Such flexible material, in addition to making the bobbin 10 suitable for being bent, thus causing the ends of the elongated tubes to be opposite to each other, because the bobbin 10 remains Such a flexible material also provides the added advantage of being sufficiently insulated to withstand the voltage stress between the magnetic core and the coil windings in the toroidal transformer as part of the final assembled toroidal transformer manufactured according to the method of the present invention. The flexible m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com