Aeration expanding pressure sealing method and sealer for flexible pipe

A sealing device and inflation expansion technology, applied in the directions of sealing, engine sealing, packaging, etc., can solve the problems of flexible covering material damage and poor reliability, and achieve the effect of quick sealing and unsealing, not easy to damage, and improved safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In the tank-type anaerobic and aerobic fermentation to produce biogas and organic fertilizer, one end of the reinforced concrete structure of the fermentation tank is closed, and the other end is open, that is, the top and one end of the tank are open. Using the continuous process of anaerobic fermentation and aerobic fermentation, the upper surface of the tank and one end surface must be sealed for anaerobic fermentation and open for aerobic fermentation. The problem can be solved by adopting the present invention.

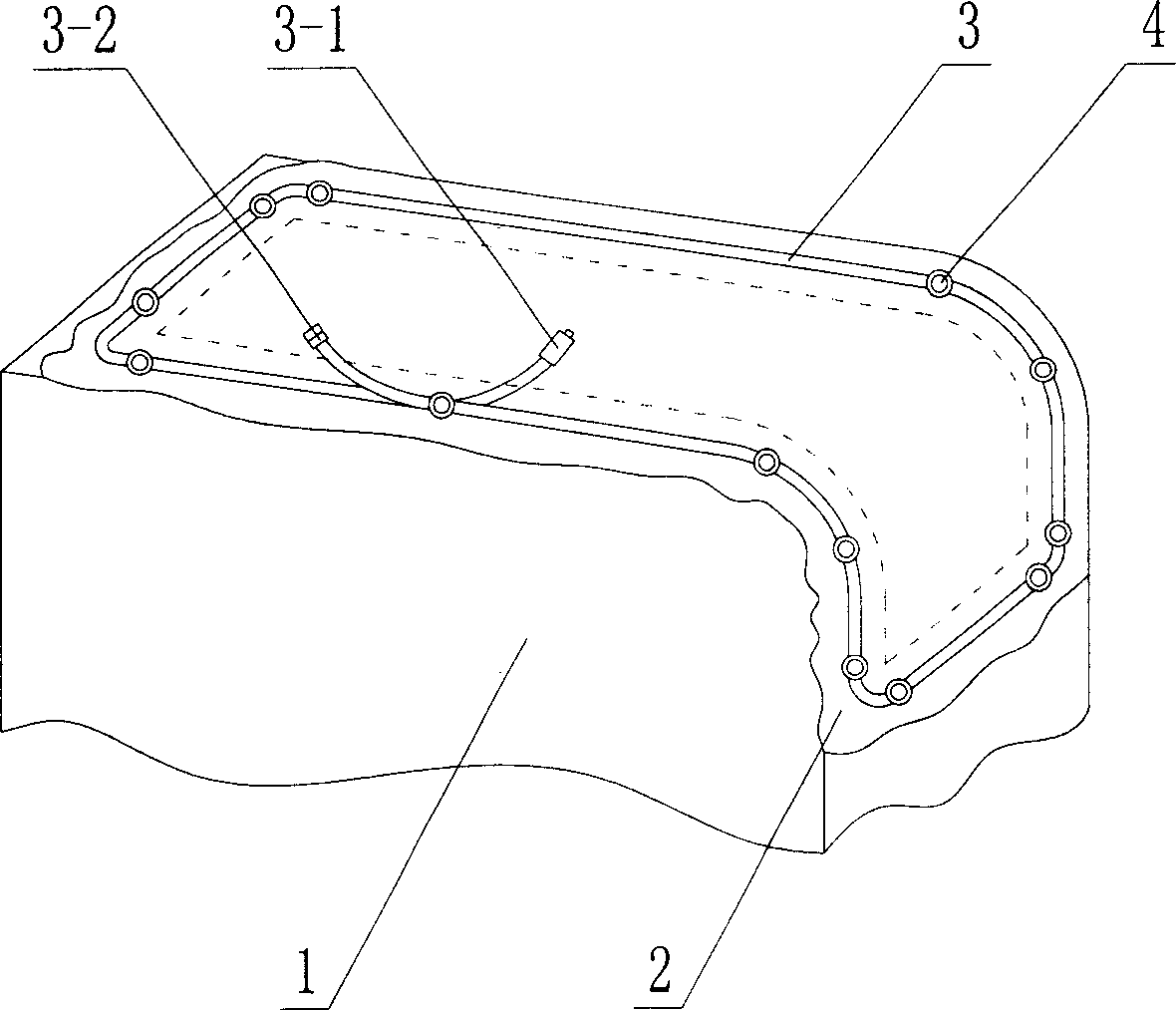

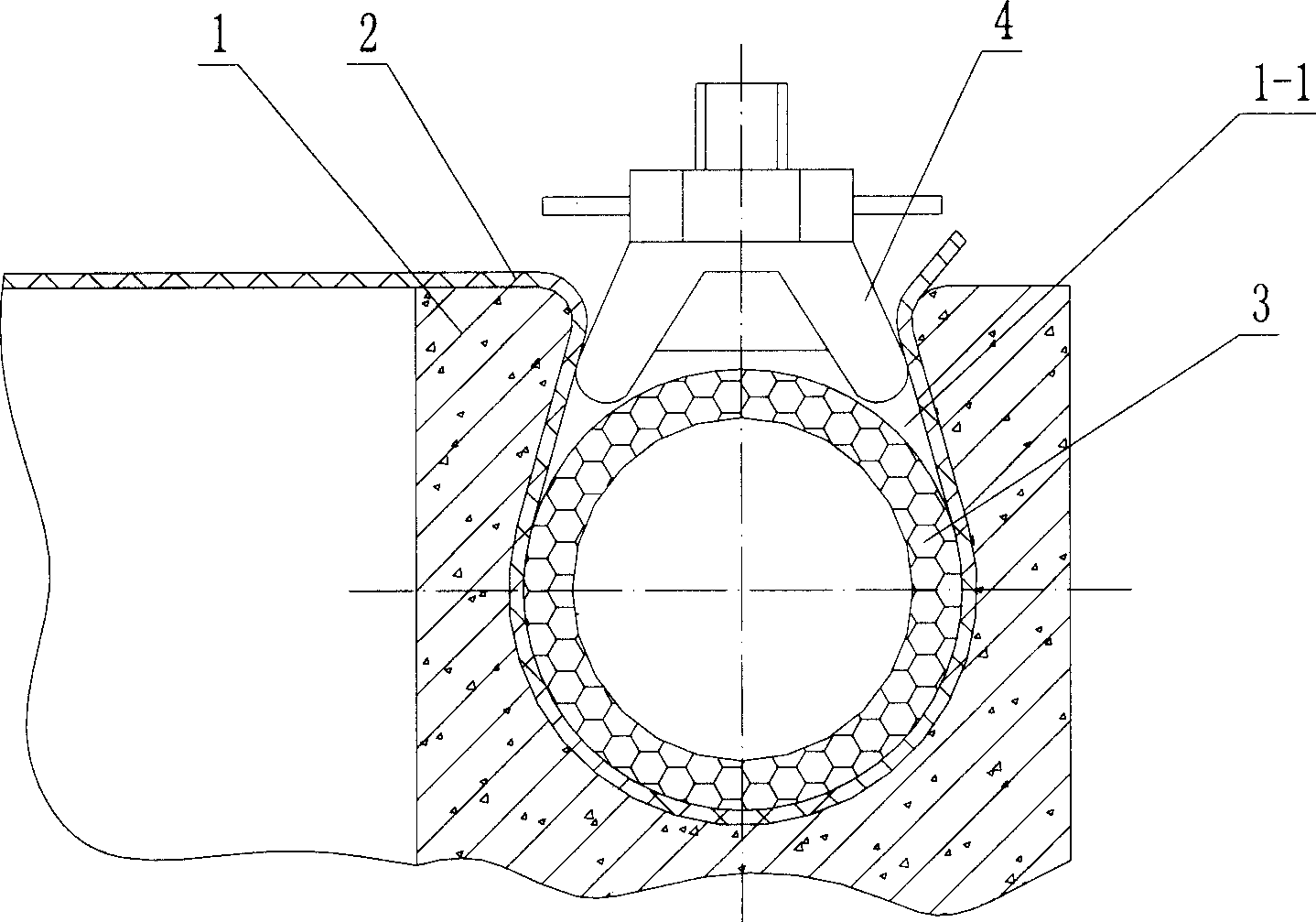

[0012] figure 1 , figure 2 It is a schematic diagram of the present invention, a U-shaped groove 1-1 is provided in the rigid container 1, and the edge of the flexible covering material 2 is put in close to the U-shaped groove 1-1, and the hose 3 is embedded in the U-shaped groove 1-1, and pressed against the U-shaped groove 1-1. Flexible cover material 2 on. Close the hose deflation valve 3-2 tightly, fill the hose 3 with a certain pressure of gas fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com