Fibre-optical acoustic sensor

An acoustic sensor and sensor technology, applied to instruments, measuring ultrasonic/sonic/infrasonic waves, measuring devices, etc., can solve the problems of sensor sensitivity drop and measurement range reduction, and achieve the elimination of parasitic interference effects, good measurement accuracy, and low error small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

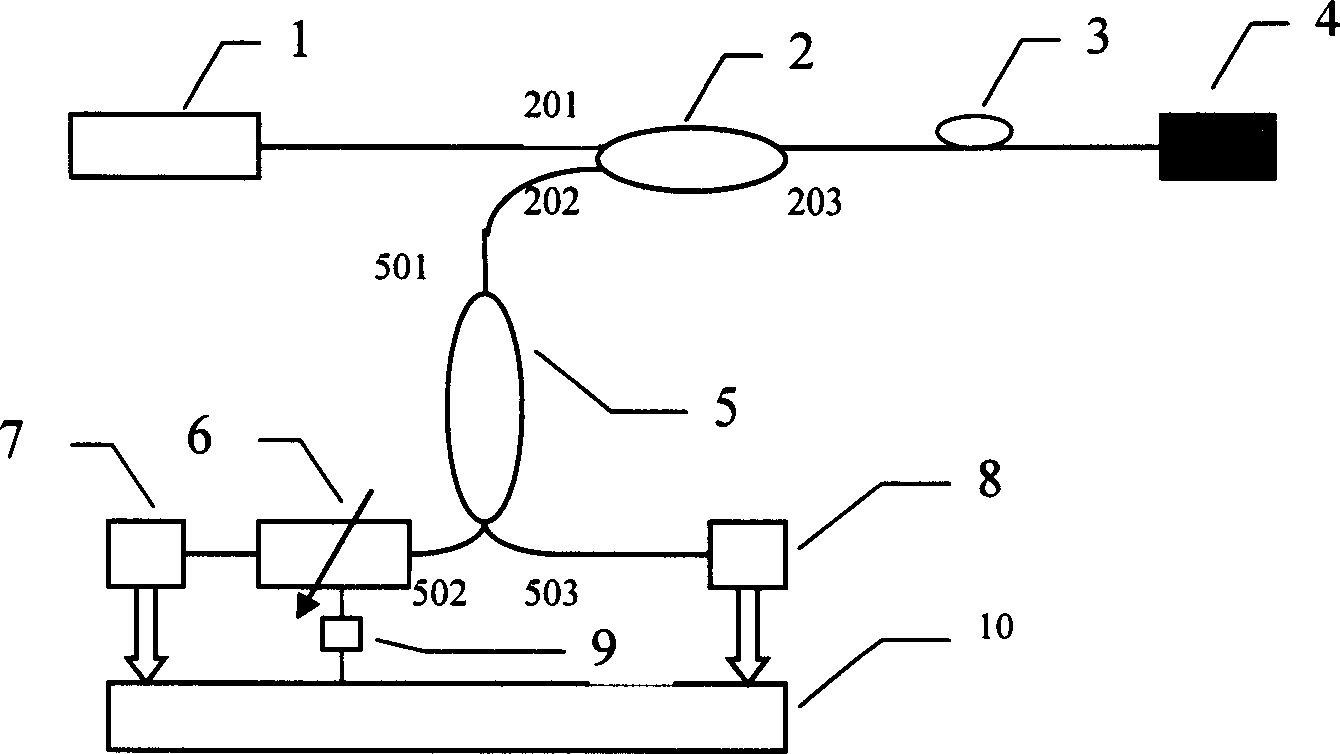

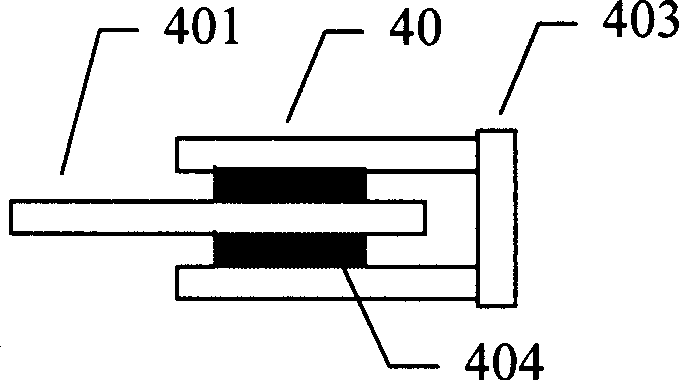

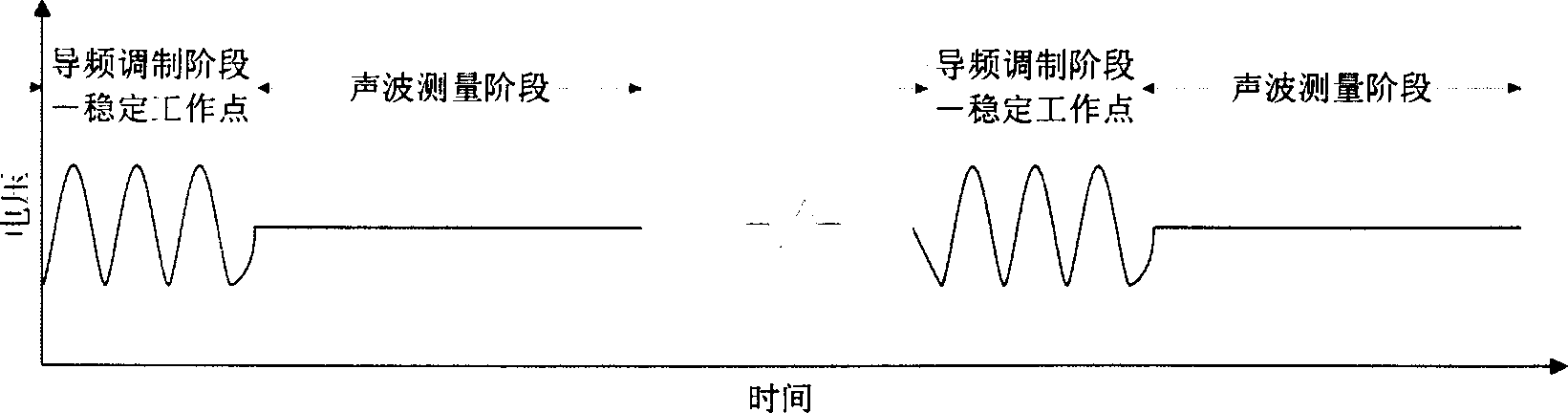

[0020] see first figure 1 , figure 1 It is a structural schematic diagram of the optical fiber acoustic sensor of the present invention. As can be seen from the figure, the optical fiber acoustic sensor of the present invention is an extrinsic optical fiber Fabry-Perot acoustic sensor, comprising a light source module 1 with pigtail output, characterized in that its composition is: the light source module 1 and an optical fiber multiplexing element 2 connected to the first port 201, the third port 203 of the optical fiber light guiding element 2 is connected to the extrinsic optical fiber Fabry-Perot interference sensor head 4 through the optical fiber 3, the second port 202 of the optical fiber light guiding element 2 It is connected with the first port 501 of the optical fiber splitter 5, and the second port 502 of the optical fiber splitter 5 is connected with the tunable optical fiber bandpass filter 6, and the tunable optical fiber bandpass filter 6 is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com