Electronic pressure switch

A pressure switch, electronic technology, applied in electronic switches, electric switches, electric fluid pressure control and other directions, can solve problems such as malfunction, shortened service life, damage to water pump seals, etc., to prevent malfunction, easy operation, Reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

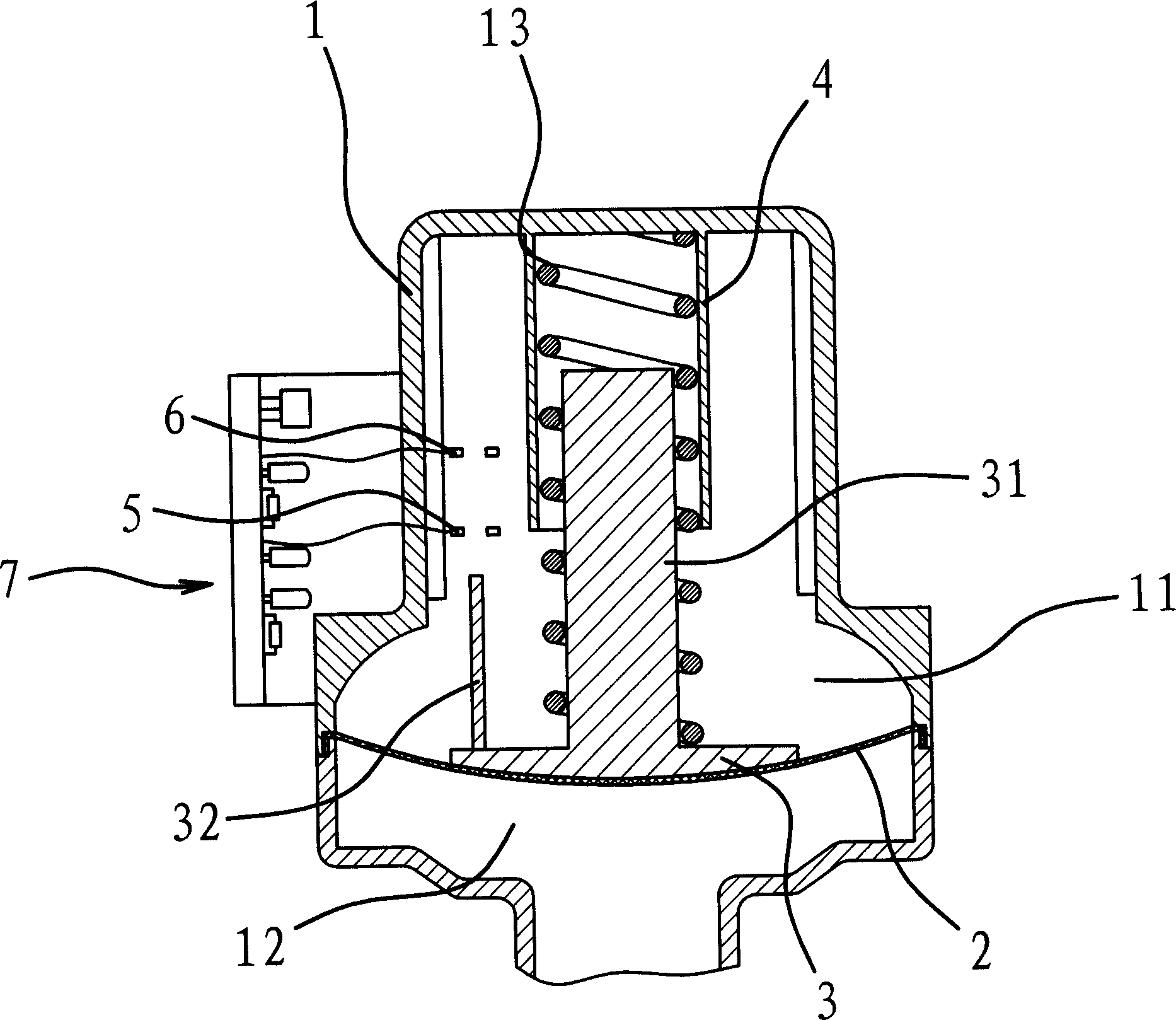

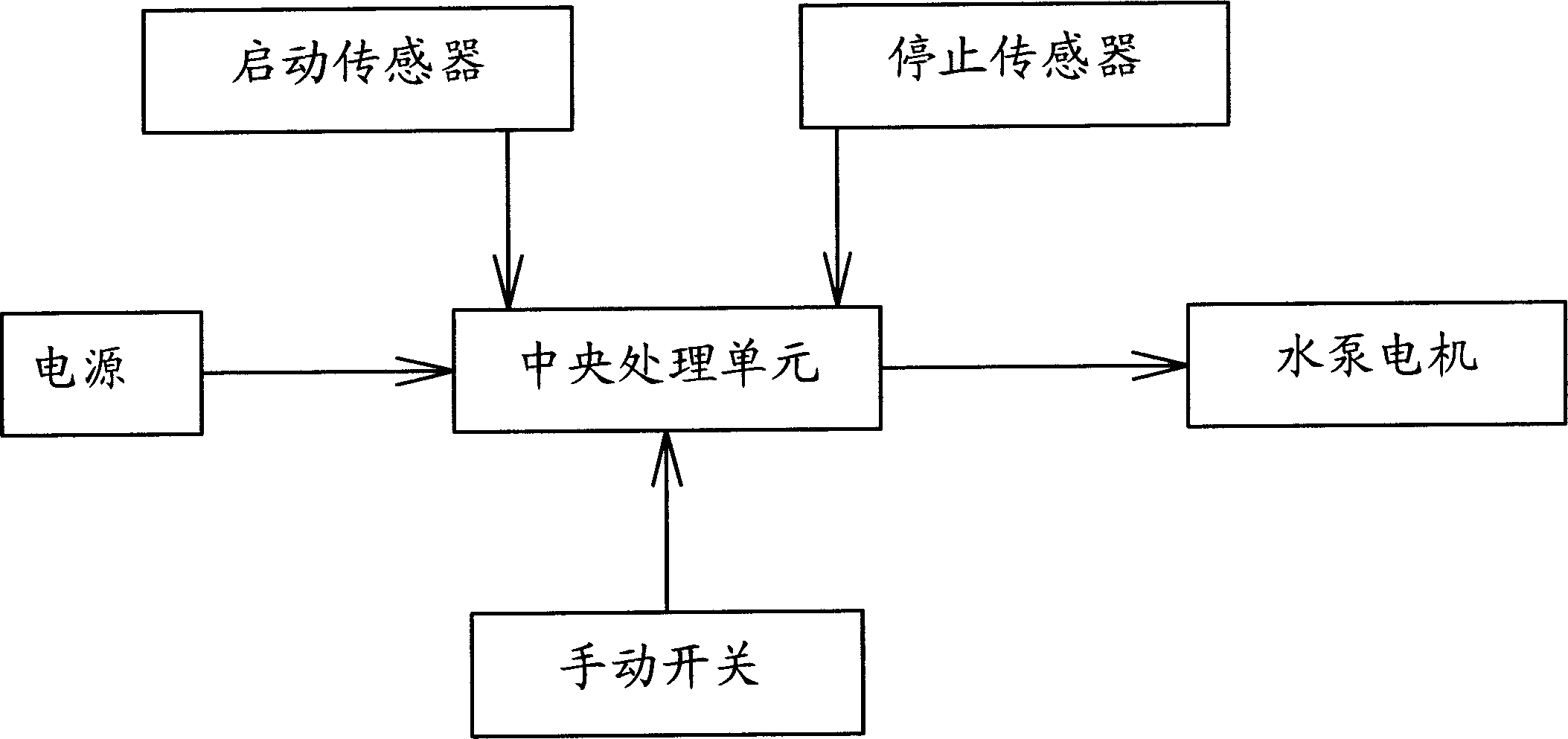

[0032] Such as figure 1 and figure 2 As shown, the electronic pressure switch is composed of a housing 1, a control circuit 7, a movable platen 3, a sealing ring 2, a spring 4, and the like.

[0033] The inside of the housing 1 is a cavity, and two pressure plates are respectively provided on both sides of the housing 1 , and the sealing ring 2 is fixedly connected in the housing 1 through the two pressure plates. In order to simplify parts and facilitate assembly, the housing 1 in this embodiment is divided into an upper housing and a lower housing, and the sealing ring 2 is tightly pressed on the joint between the upper housing and the lower housing.

[0034] The sealing ring 2 separates the cavity of the housing 1 into two cavities, the movable chamber 11 and the water inlet chamber 12 , and the movable chamber 11 and the water inlet chamber 12 are not connected.

[0035] The movable platen 3 is arranged in the movable cavity 11 , and the bottom of the movable platen 3 i...

Embodiment 2

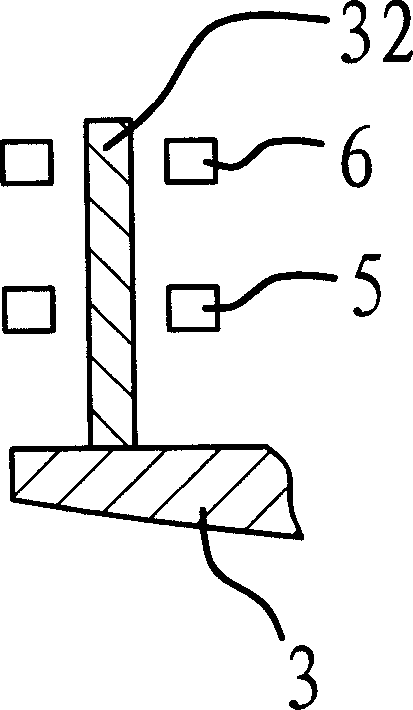

[0044] Such as Figure 6 and Figure 7 and Figure 8 As shown, the structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that the pressure baffle 32 is two pieces, and they are respectively vertically fixed on the movable pressure plate 3 on both sides of the guide post 31, and the two pressure baffles The lengths of the pressure baffles 32 are different. The above-mentioned start sensor 5 and stop sensor 6 are respectively arranged at the two pressure baffles 32 .

[0045] When the water pipe was dry or the water pump was stuck, after the water pump worked for a period of time, the water pressure still dropped, and the pressure baffle plate 32 dropped to the position that did not block the two sensors. Obviously, at this time, the water pump will automatically stop after working for a certain period of time. This plays a role in protecting the water pump motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com