Liquid drop regulating method, liquid drop discharging method, and liquid drop discharging device

一种调整方法、液滴量的技术,应用在对表面涂布液体的装置、喷射装置、喷射装置等方向,能够解决不放出液滴等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Although the embodiments of the present invention are described below with reference to the drawings, the present invention is not limited to the embodiments of the present invention.

[0023] Example.

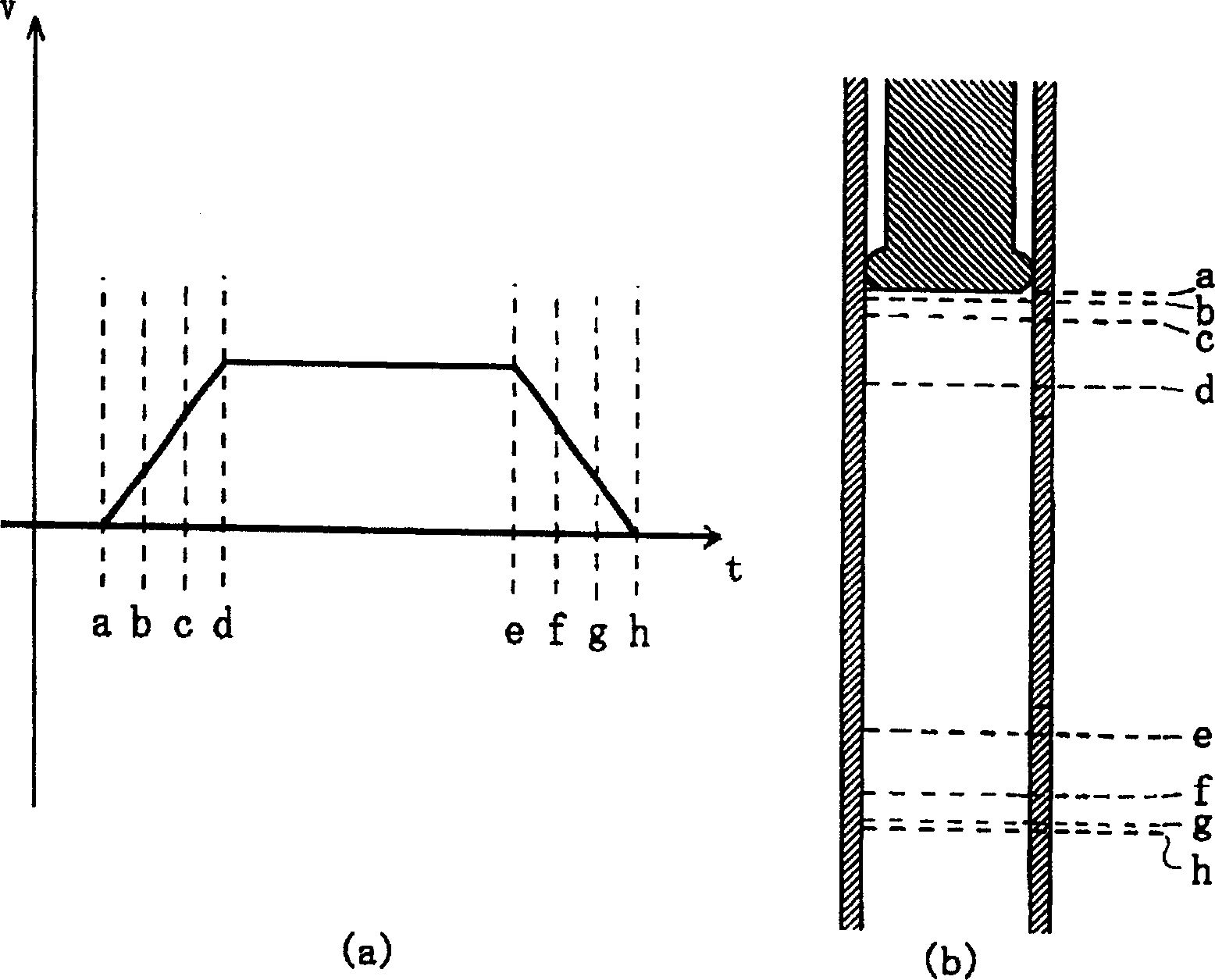

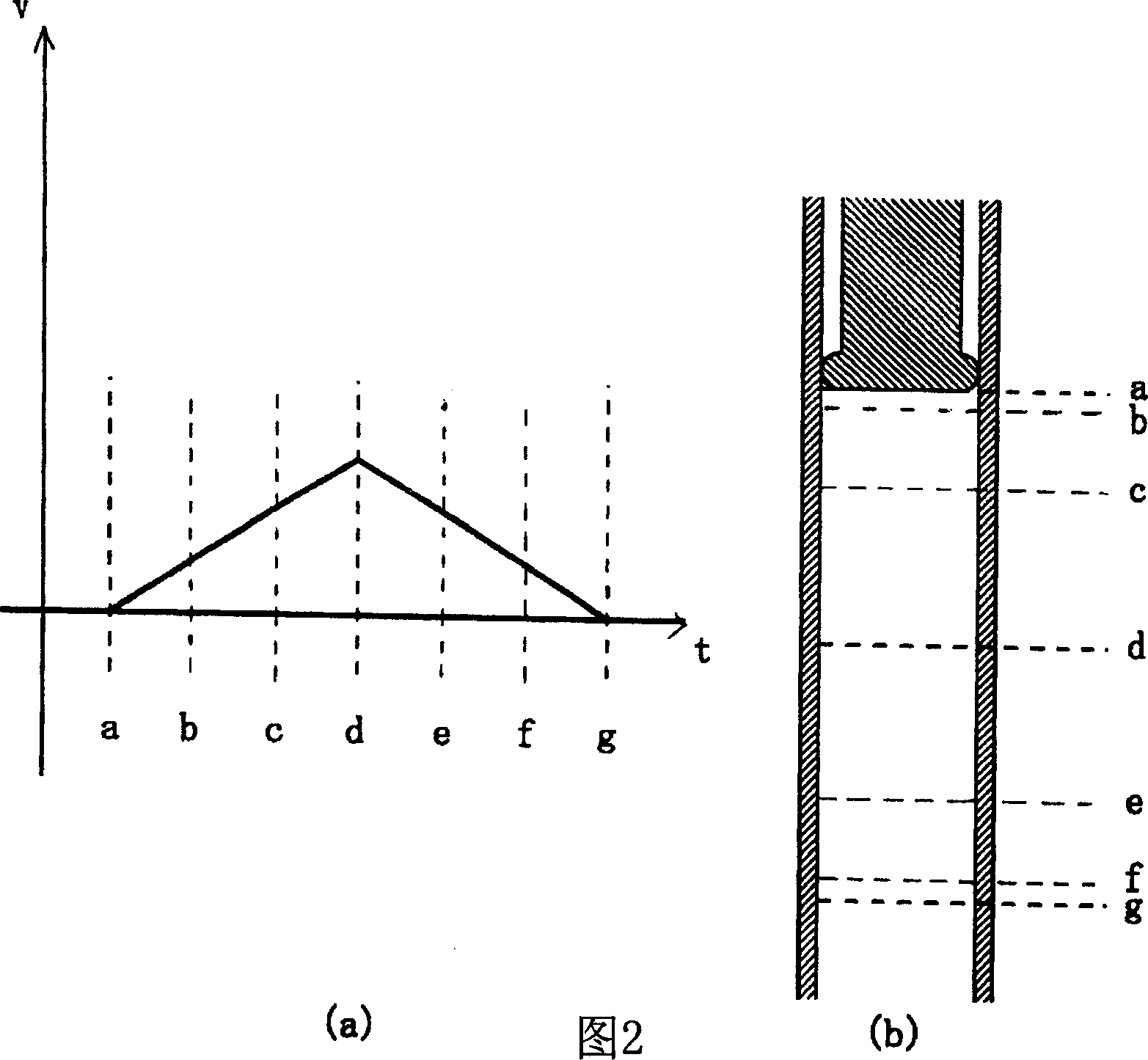

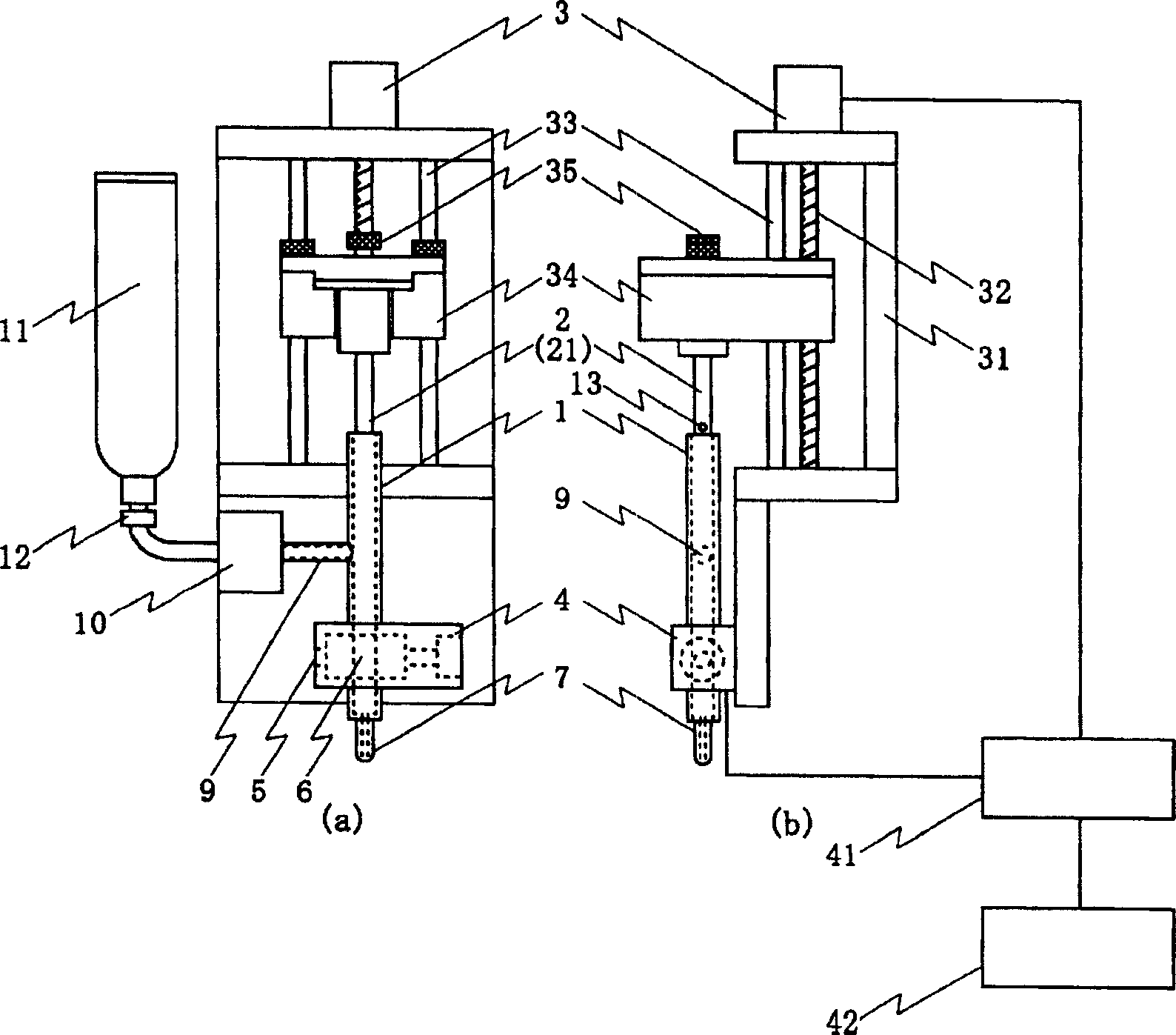

[0024] Such as image 3 As shown, the figure includes: a frame body, a release part supported by the frame body, a liquid material storage container and a control part that can control the release state of the liquid material. The components of the frame body 31 include: a frame body, which supports the guide rod 33 and screw shaft 32, the guide rod 33 guides the plunger support body 34 up and down, and the screw shaft 32 makes the plunger support body 34 driven by the motor 3 on the top of the frame body 31 move in the up and down direction; the lower frame body, which supports the discharge valve 4, the liquid material supply valve 10 and supports the metering section 1 through the discharge valve 4.

[0025] In the measuring part 1 supported by the frame body 31 an...

Embodiment 2

[0036] In the droplet forming device involved in Example 1, since air remains in the piping during filling, the pressure response may become dull due to the compressibility of the residual air. Therefore, the droplet forming device involved in this embodiment, It is attached on the plunger 2 of the droplet forming device related to embodiment 1 Figure 4 Air bubble extraction parts shown.

[0037] Plunger 2 comprises: plunger rod 21, and it has tubular portion, and aforementioned tubular portion has the hole 13 that communicates with outer wall surface; The air bubble removal hole 23 of the tubular part of 21 has a sealing part 24 on its outer wall that is closely attached to the inner wall surface of the metering part;

[0038] The upper part of the plunger rod 21 has a large-diameter cylindrical portion, and a flange portion is formed on the upper end portion, and the plunger rod 21 is fixed to the plunger support body 34 by this flange portion.

[0039] In the aforementio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com