Electric pressure cooker capable of controlling pressure precisely

An electric pressure cooker, precise control technology, applied in pressure cooker and other directions, can solve the problems of scald operation and bystanders, high manufacturing process requirements, poor work reliability, etc., and achieve good heat insulation effect, high safety degree, and rapid exhaust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

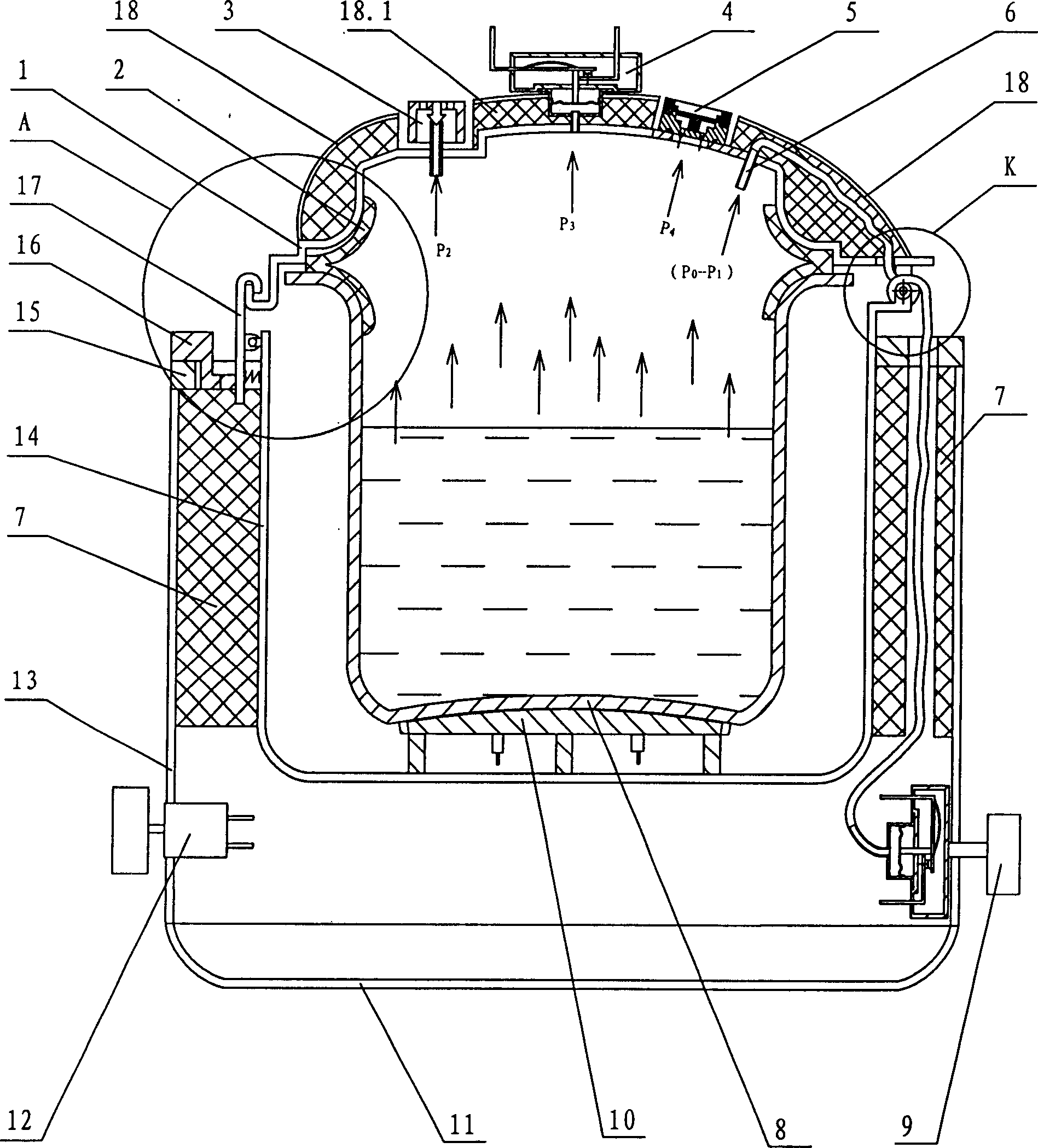

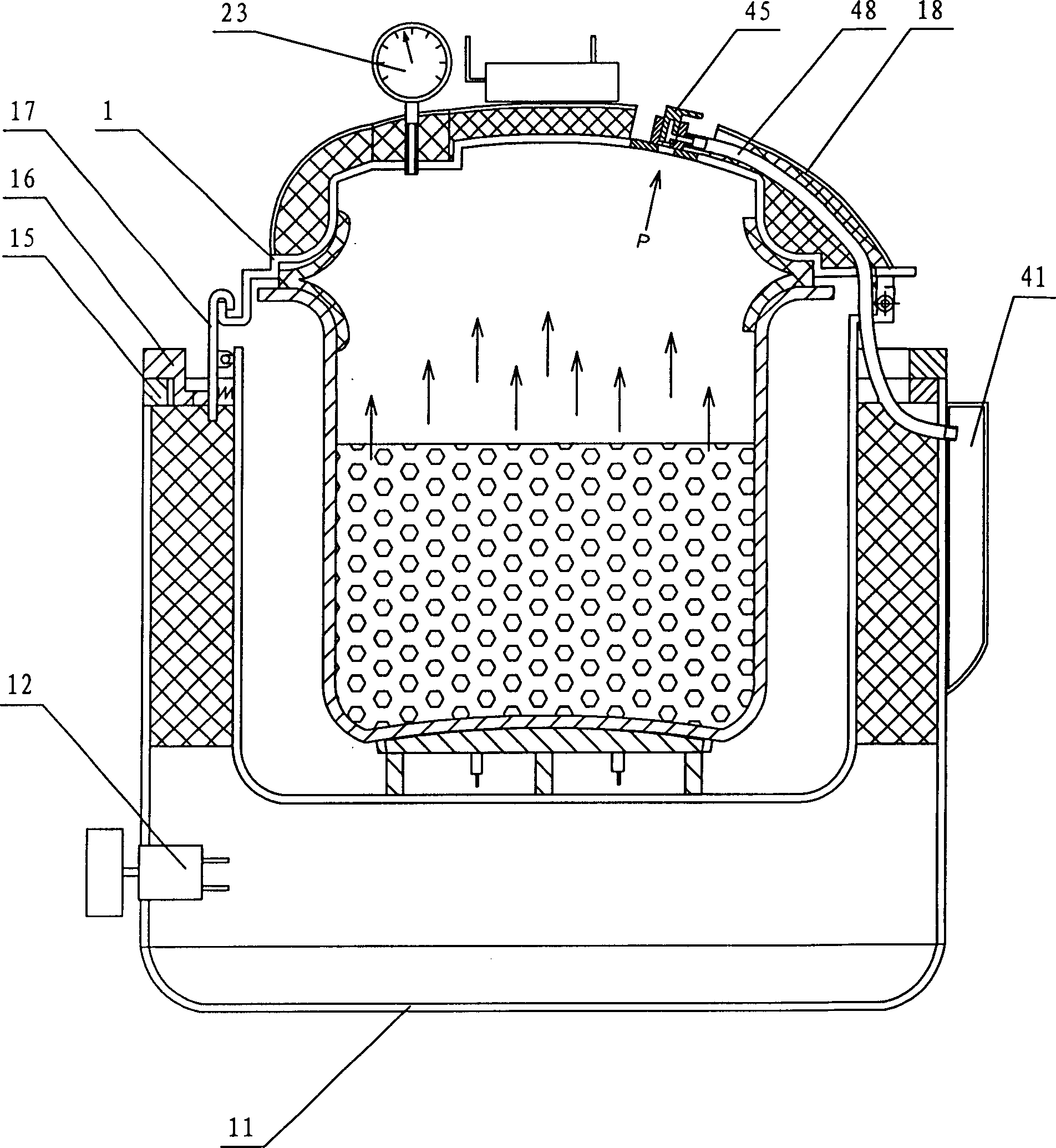

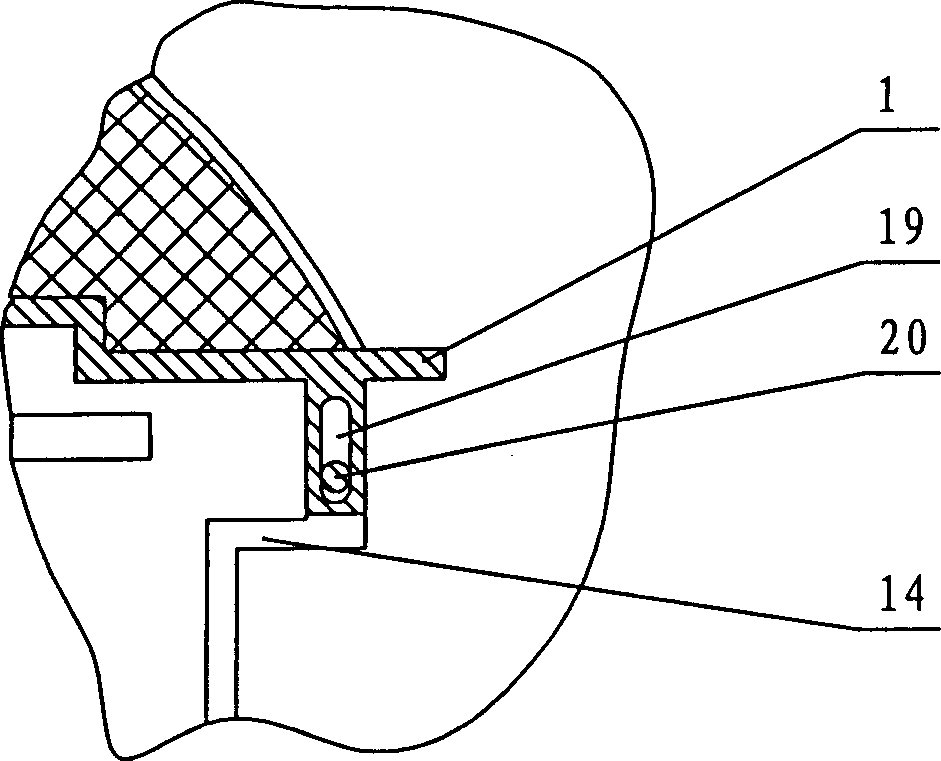

[0039] In the figure, 1 is the pot cover, 2 is the elastic rubber sealing ring, 3 is the gravity pressure limiting valve, 4 is the manual reset pressure switch, 5 is the overpressure safety valve, 6 is the air guide pipe or channel, and 7 is the heat insulation layer. 8 is the inner pot, 9 is the automatic reset adjustable air pressure switch, 10 is the electric heating plate, 10.1 is the copper heat conduction layer, 11 is the chassis, 12 is the electric timer starter, 13 is the shell, 14 is the medium pot, 15 is the connecting ring, 16 is a locking ring, 16.1 is an inclined chute, 17 is a buckle plate, 18 is a heat shield, 19 is an oblong chute, 20 is a hinge shaft of a medium pot, 21 is a torsion spring, 23 is a thermometer, 24 is a valve Core, 25 is the insurance piece, 26 is the valve cover, 27 is the valve seat, 28 is the sealing ring, 29 is the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com