Taking lens system

A lens system and lens technology, applied in the fields of lenses, instruments, optics, etc., can solve the relationship between the inappropriate shape of the first lens element, difficulty in manufacturing peripheral performance, and the focal power of the first and second lens elements Inappropriate and other problems, to achieve the effect of low cost, small cost, and reduced sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

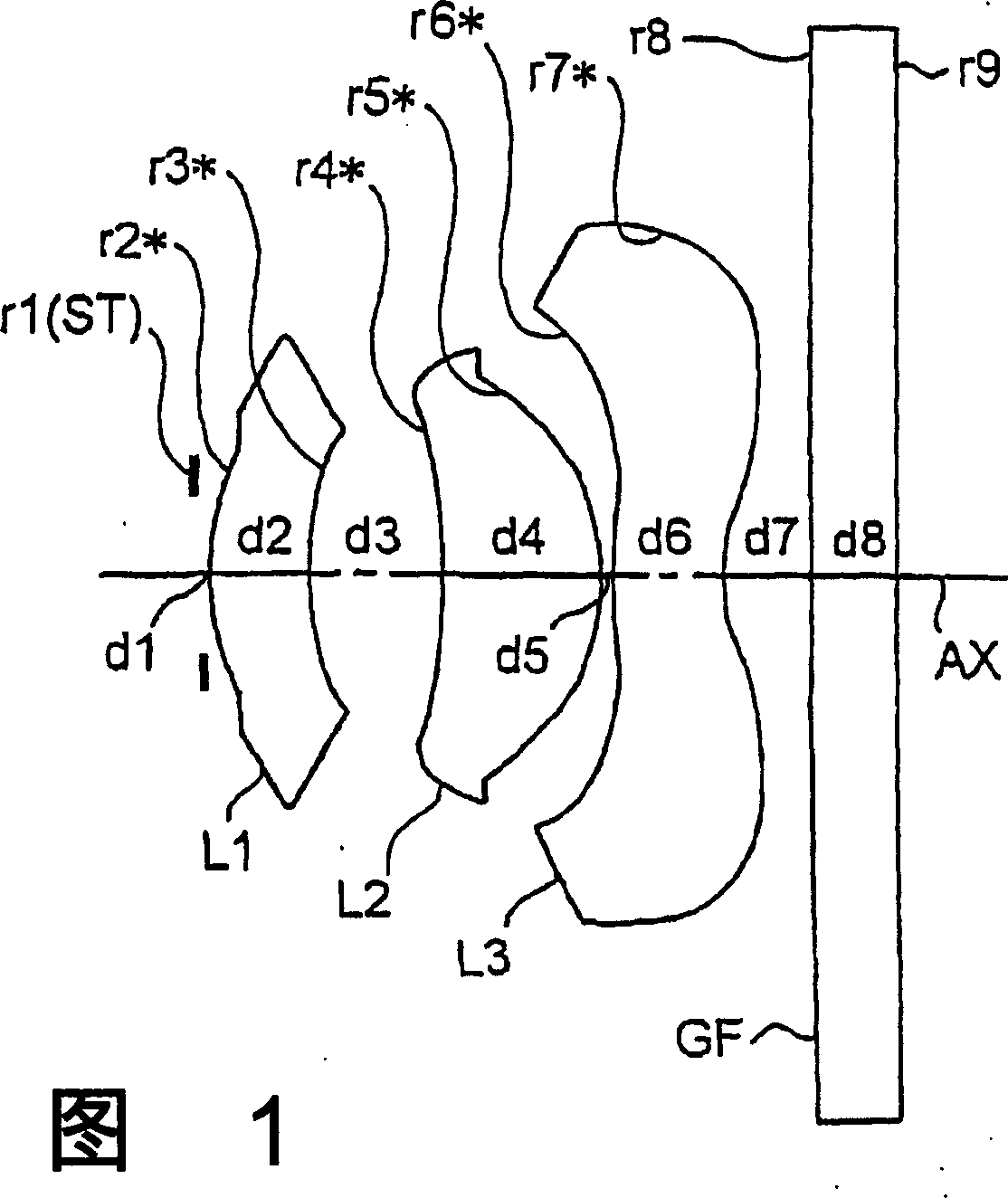

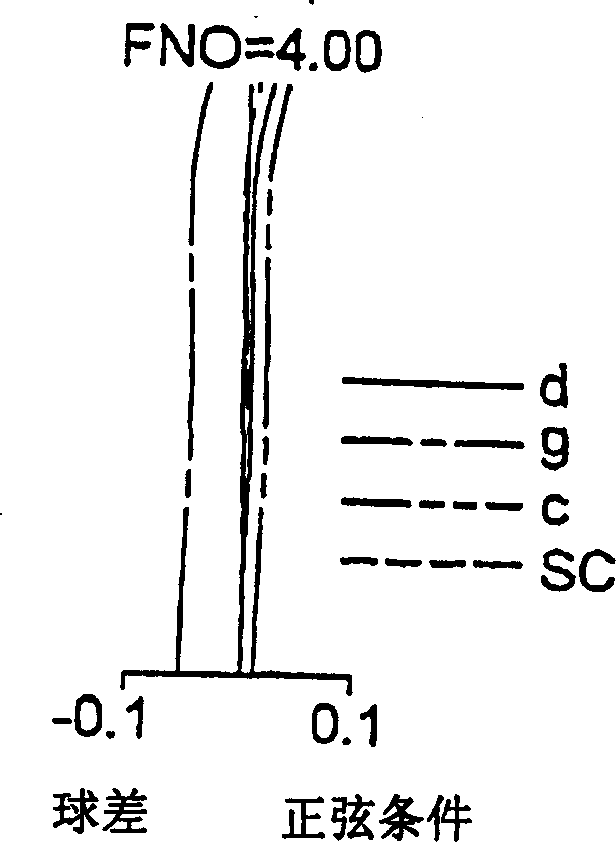

example 1

[0100] [Asphere data of surface r2]

[0101] ε=-0.77750×10, A4=0.30133, A6=-0.18716

[0102] [Asphere data of surface r3]

[0103] ε=-0.32536×10, A4=0.12859, A6=0.96276×10 -1

[0104] [Asphere data for surface r4]

[0105] ε=-0.17634×10 2 , A4=0.16810, A6=0.37183×10 -1 , A8=0.13745, A10=-0.27842×10 -1

[0106] [Asphere data of surface r5]

[0107] ε=0.29577, A4=0.49555×10 -1 , A6=-0.17811×10 -1 , A8=-0.14756×10 -1 , A10=0.29727×10 -1

[0108] [Asphere data of surface r6]

[0109] ε=0.17544×10, A4=-0.24387, A6=0.11001, A8=-0.45300×10 -1 , A10=0.24779×10 -1 , A12=-0.87870×10 -2

[0110] [Asphere data for surface r7]

[0111] ε=-0.40000×10, A4=-0.15919, A6=0.91191×10 -1 , A8=-0.38452×10 -1 , A10=0.91696×10 -2 , A12=-0.97609×10 -3

[0112] Table 2

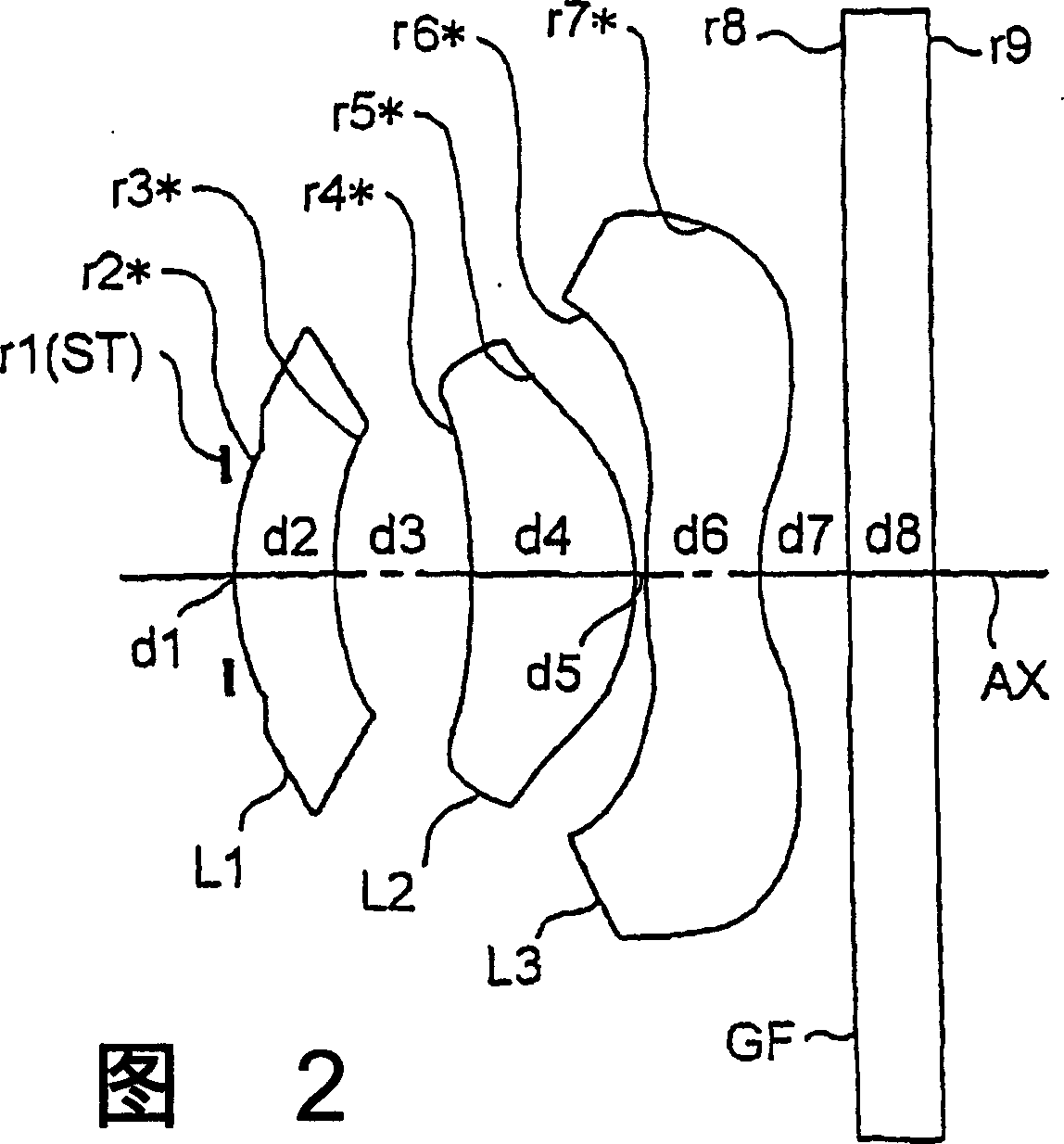

example 2

[0115] [Asphere data of surface r2]

[0116] ε=-0.52989×10, A4=0.28235, A6=-0.14635

[0117] [Asphere data of surface r3]

[0118] ε=-0.35960×10, A4=0.13545, A6=0.68161×10 -1

[0119] [Asphere data for surface r4]

[0120] ε=-0.68322×10, A4=-0.38560×10 -1 , A6=-0.22741×10 -1 , A8=0.94379×10 -2 , A10=0.36530×10 -1

[0121] [Asphere data of surface r5]

[0122] ε=0.45134, A4=-0.16882×10 -1 , A6=-0.44234×10 -2 , A8=0.17818×10 -1 , A10=0.55365×10 -2

[0123] [Asphere data of surface r6]

[0124] ε=0.20629×10, A4=-0.33010, A6=0.13147, A8=-0.49477×10 -1 , A10=0.31953×10 -1 , A12=-0.10098×10 -1

[0125] [Asphere data for surface r7]

[0126] ε=-0.40000×10, A4=-0.15498, A6=0.82349×10 -1 , A8=-0.35200×10 -1 , A10=0.88419×10 -2 , A12=-0.95148×10 -3

[0127]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap