Manufacturing method for coil of electronic expansion valve

An electronic expansion valve and the technology of the manufacturing method are applied in the direction of valve operation/release device, valve details, valve device, etc., which can solve the problems that cannot be organically fused together, the molding process takes a long time, and the material cannot be recycled. Achieve the effects of avoiding the cracking of plastic parts, shortening the molding time and lowering the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

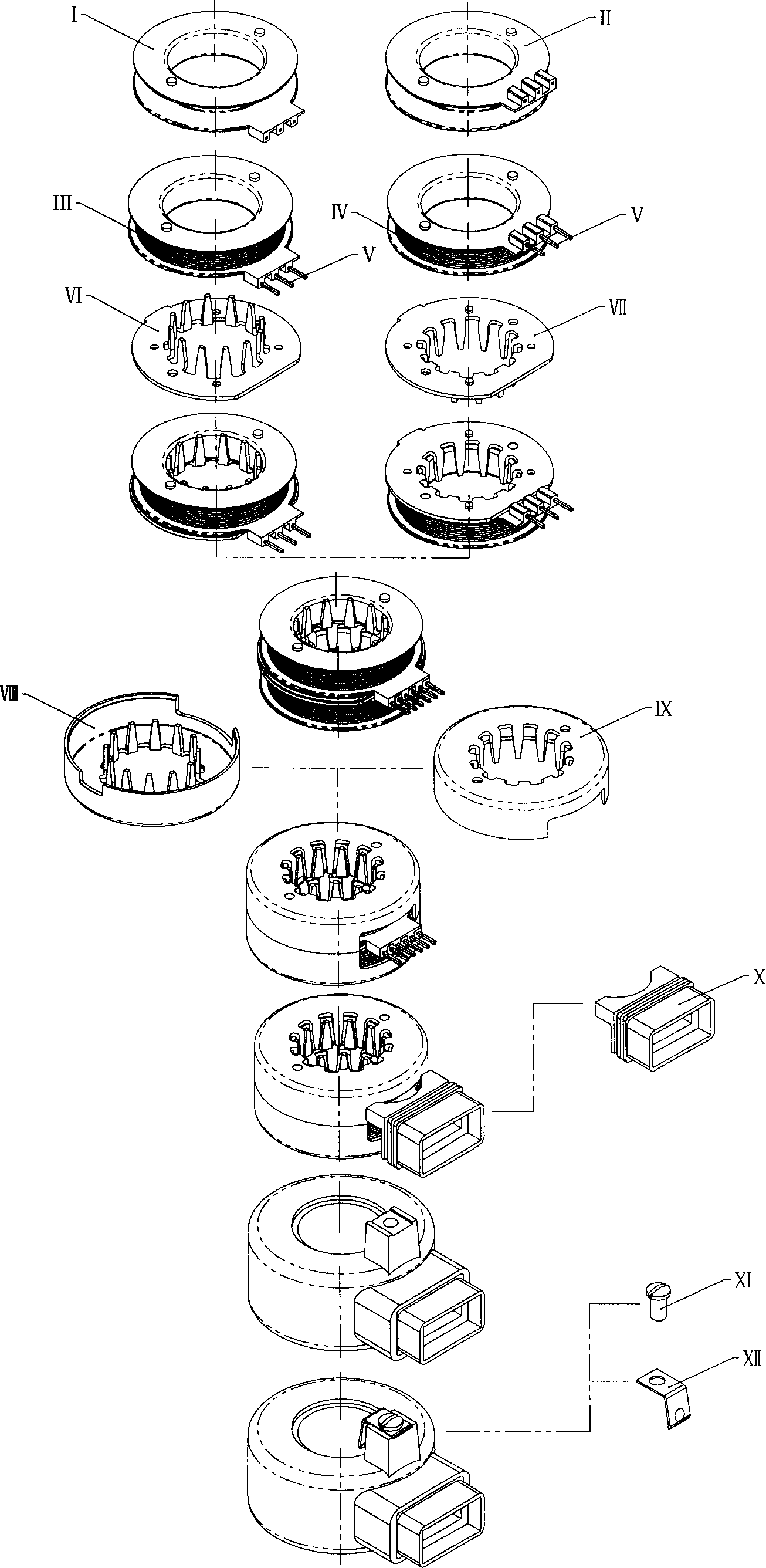

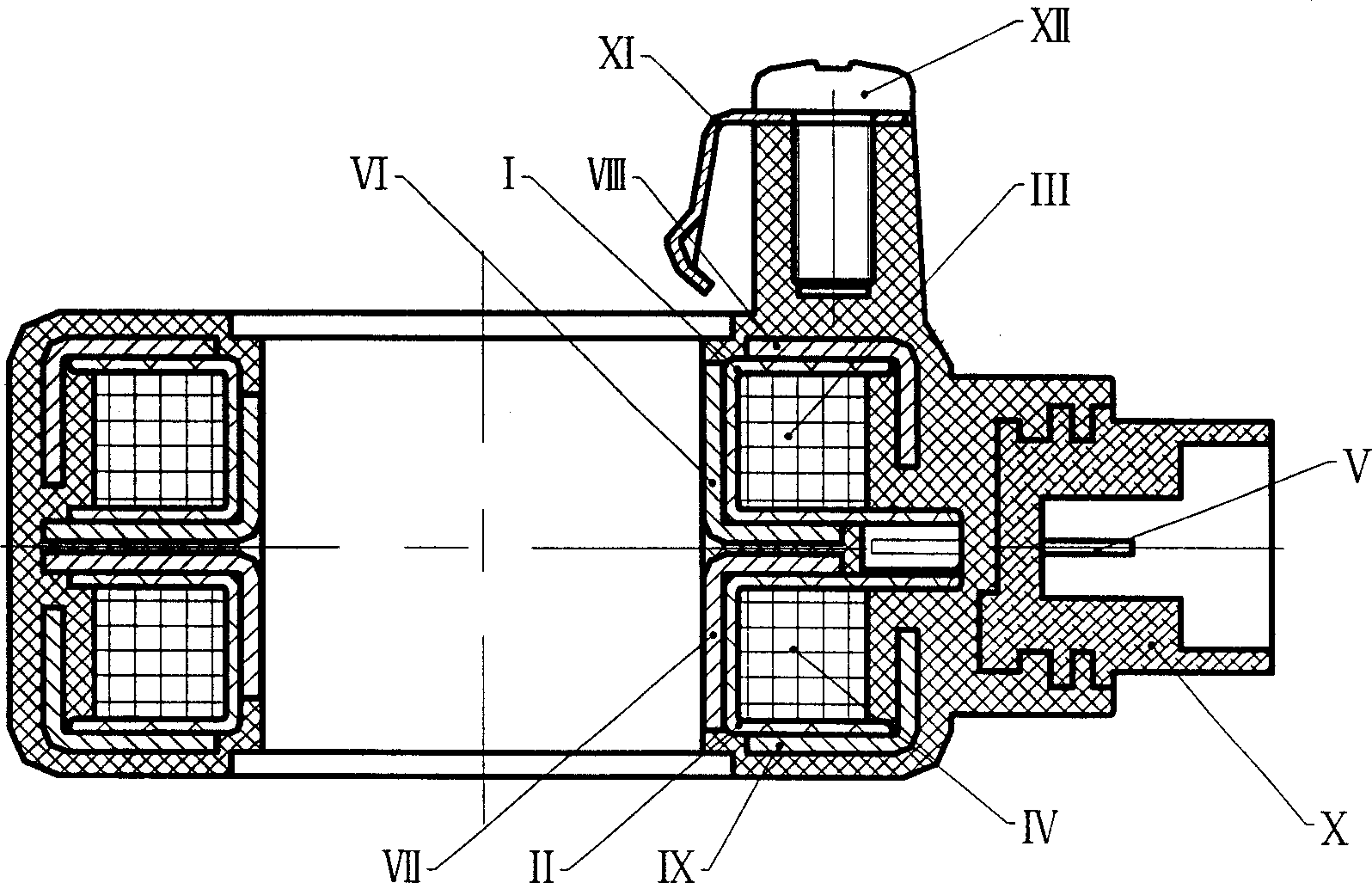

[0016] Such as Figure 3-6 The manufacturing process of the electronic expansion valve coil shown is as follows:

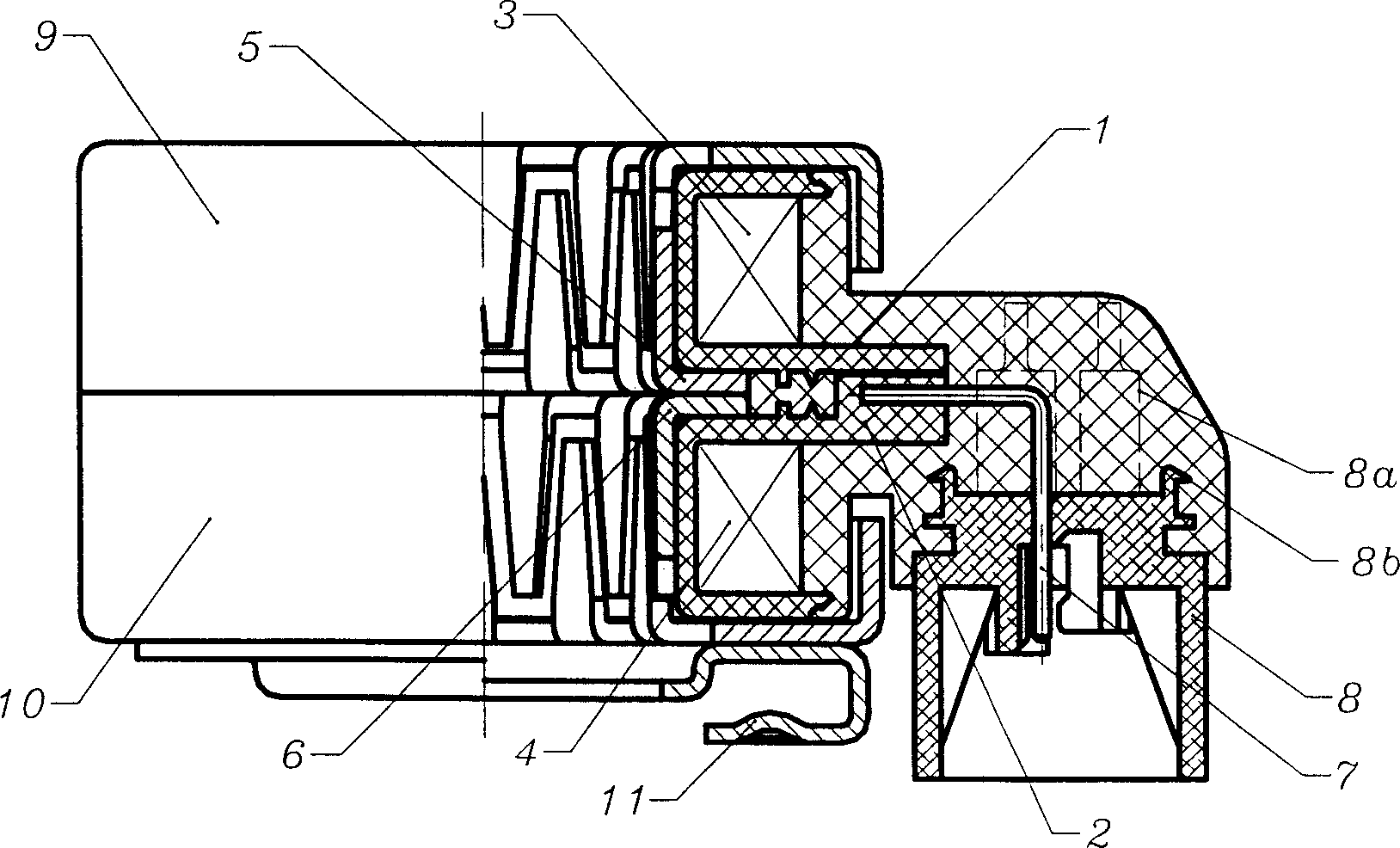

[0017] Firstly, on the upper and lower coil bobbins 1, 2, a certain number of turns of enameled wires 3, 4 are wound, and the wire ends of the enameled wires are welded together with the three pins 7 inserted in the socket ends of the bobbins to form the upper and lower coil windings. A, B, then place two magnetically conductive electromagnetic pole plates 5, 6 between the two coil windings to form the upper and lower winding parts C, D, and stack the two winding parts together to form the stator assembly E, and then After assembling the stator assembly E and the insulating sleeve socket 8, an assembly F is obtained. Before the insulating sleeve socket is assembled, five uprights 8a for pressing and locating the injection mold are arranged on its upper end, and the lower end of the positioning upright is large and the upper end is small. The upper edge of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com