Multipurpose bubble liquid film reactor

A liquid film reactor, a multi-purpose technology, applied in chemical methods for reacting liquid and gaseous media, chemical/physical/physicochemical fixed reactors, chemical instruments and methods, etc. Unable to implement continuous operation and other problems, to achieve the effect of exquisite configuration, low manufacturing cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

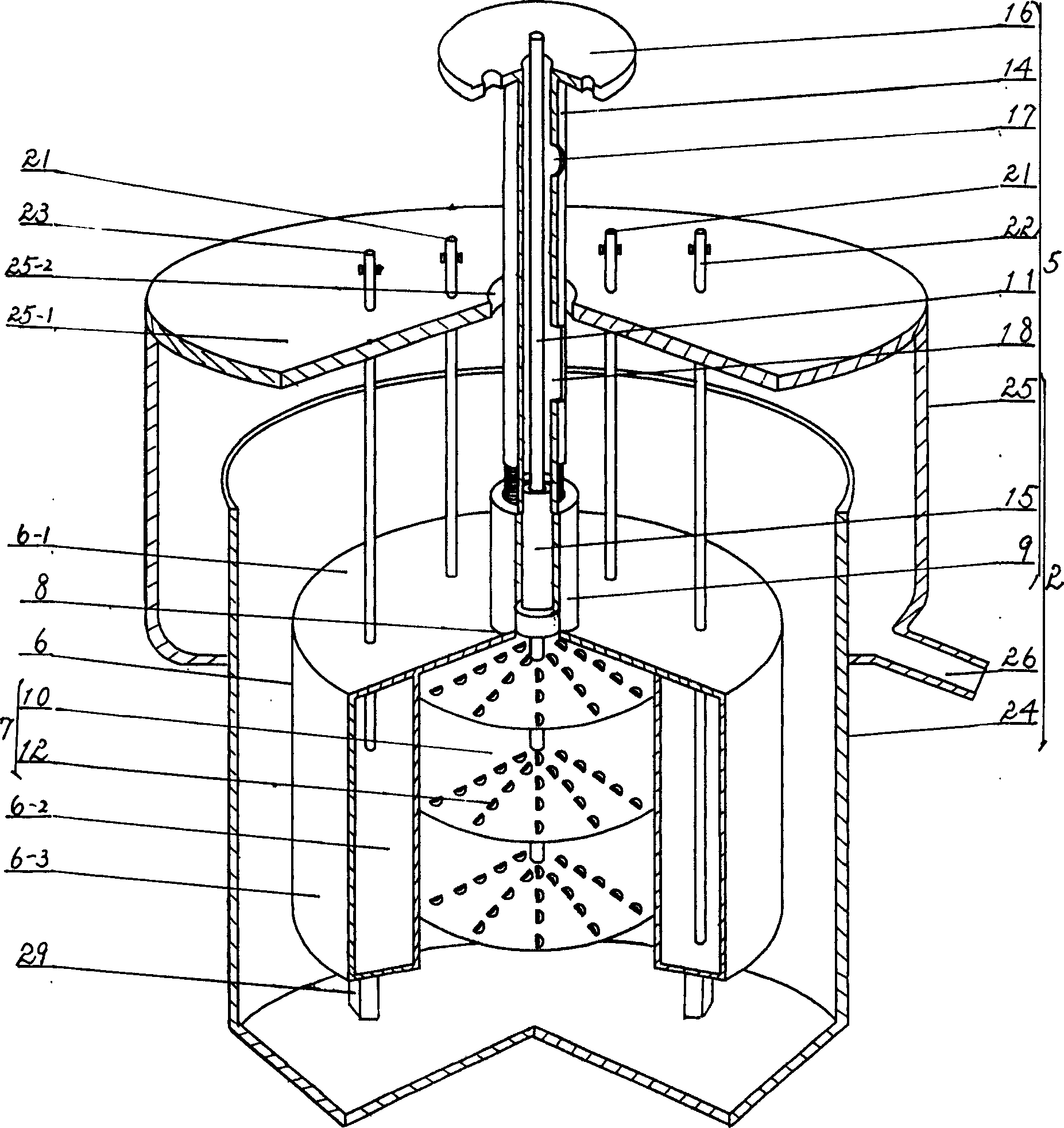

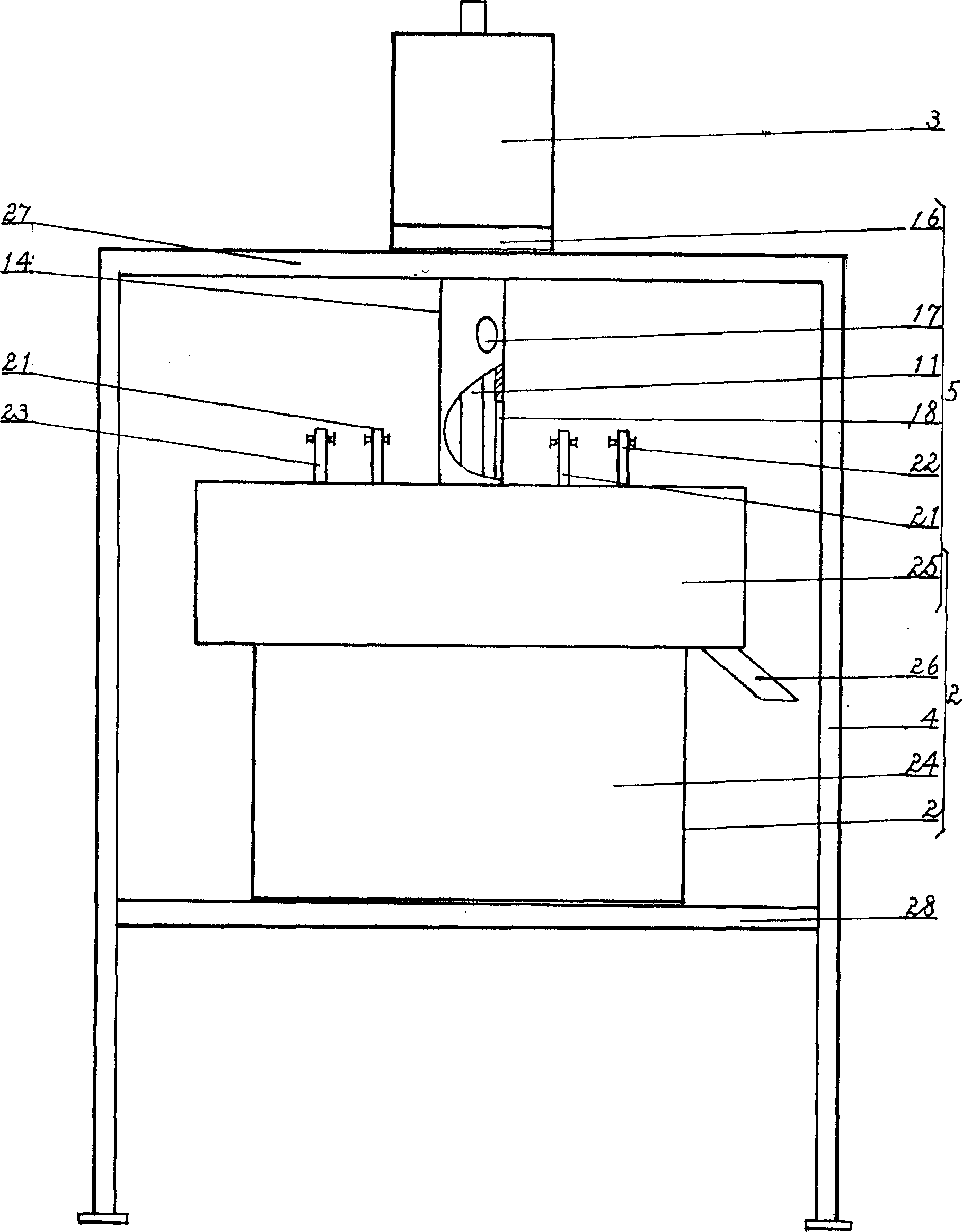

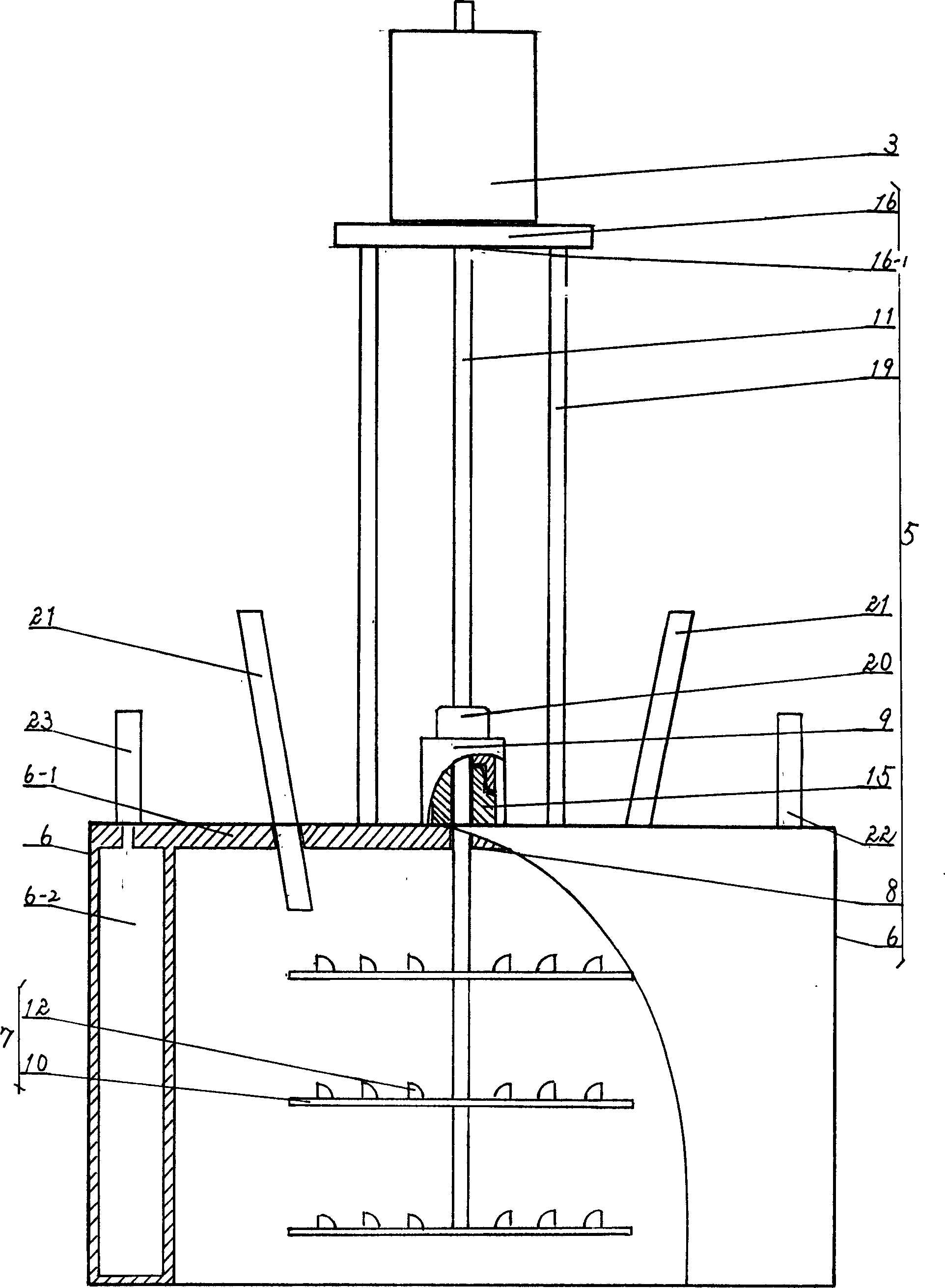

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings. The bracket 4 can support the blister dish stirrer assembly 1 of two kinds of stirrer fixing forms, and the attached figure 2It is the first connection form, which is composed of a fixed round joint 9, a cylinder 14, a fixed bearing 15 and a flange 16. The fixed round joint 9 is fixed on the center of the cover tube top plate 6-1, and one end of the cylinder 14 is connected to the flange. The blue plate 16 is connected, the fixed bearing 15 is in the fixed round joint 9, and the other end of the cylinder 6 is fastened and locked with the fixed round joint 9, and the cylinder 6 is provided with air holes 17 and air grooves 18; the second type is connected by several The column 19 connects the flange 16 with the top plate 6-1 of the cover cylinder, and the fixed bearing 15 in the fixed round joint 9 is fastened and locked by the empty pipe lock head 20 . The ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com