Metallic tube circular sealing washer and its mfg. method

A manufacturing method and technology of metal pipes, which are applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of easy bending deformation, loss of sealing performance, pressure resistance and limited compression resilience, and achieve sealing contact surface. Small, easy to install and operate, and the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

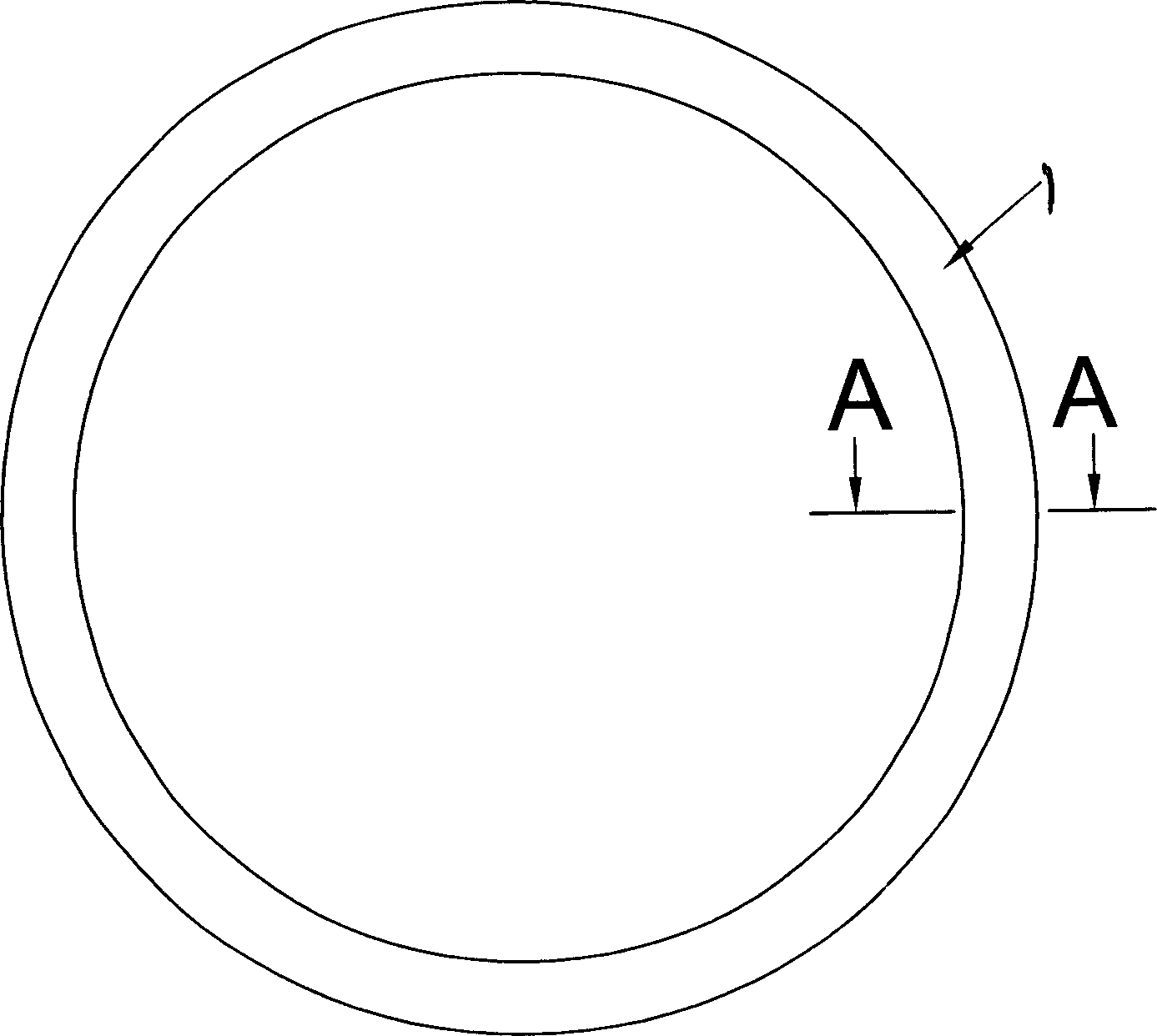

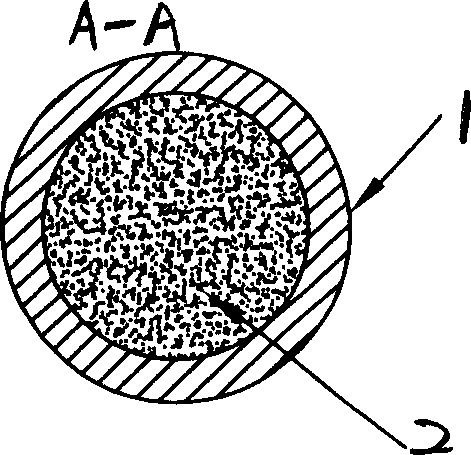

[0018] See attached figure 1 to attach figure 2 , a metal pipe ring sealing gasket, comprising a ring-shaped metal pipe 1 and a flexible sealing filler 2 filled in the inner cavity of the metal pipe 1 . The metal tube 1 is made of carbon steel, stainless steel, copper, aluminum, Monel, Inconel, titanium and other materials, and the flexible sealing filler 2 is made of non-metallic materials, such as graphite, fiber, polytetrafluoroethylene One or more mixtures of vinyl fluoride and resin.

[0019] The cross-section of the metal pipe 1 is circular. The wall thickness of the metal tube 1 is in the range of 0.1 to 3 mm, preferably in the range of 0.3 to 0.5 mm, and the outer diameter of the metal tube 1 is in the range of 2 to 50 mm, preferably in the range of 4 to 25 mm. The flexible sealing filler 2 fills the inner cavity of the metal pipe 1 .

[0020] A method for manufacturing a metal pipe ring sealing gasket, comprising the following steps: ①. Filling the inner cavity o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com