Pulse charging an electrochemical device

An inductance and current technology, used in electroplating and electrochemical conversion technology, which can solve problems such as short current pulses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

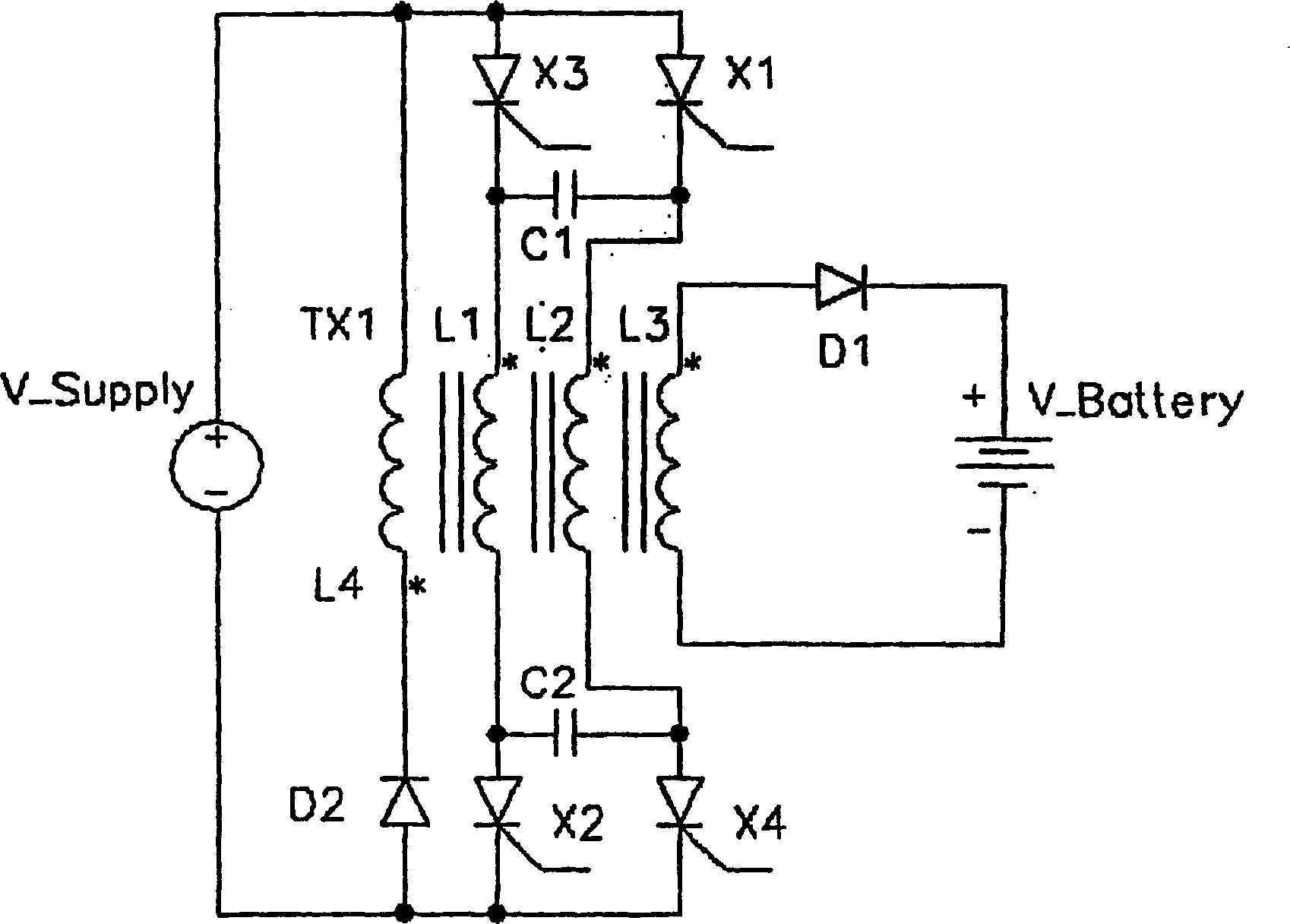

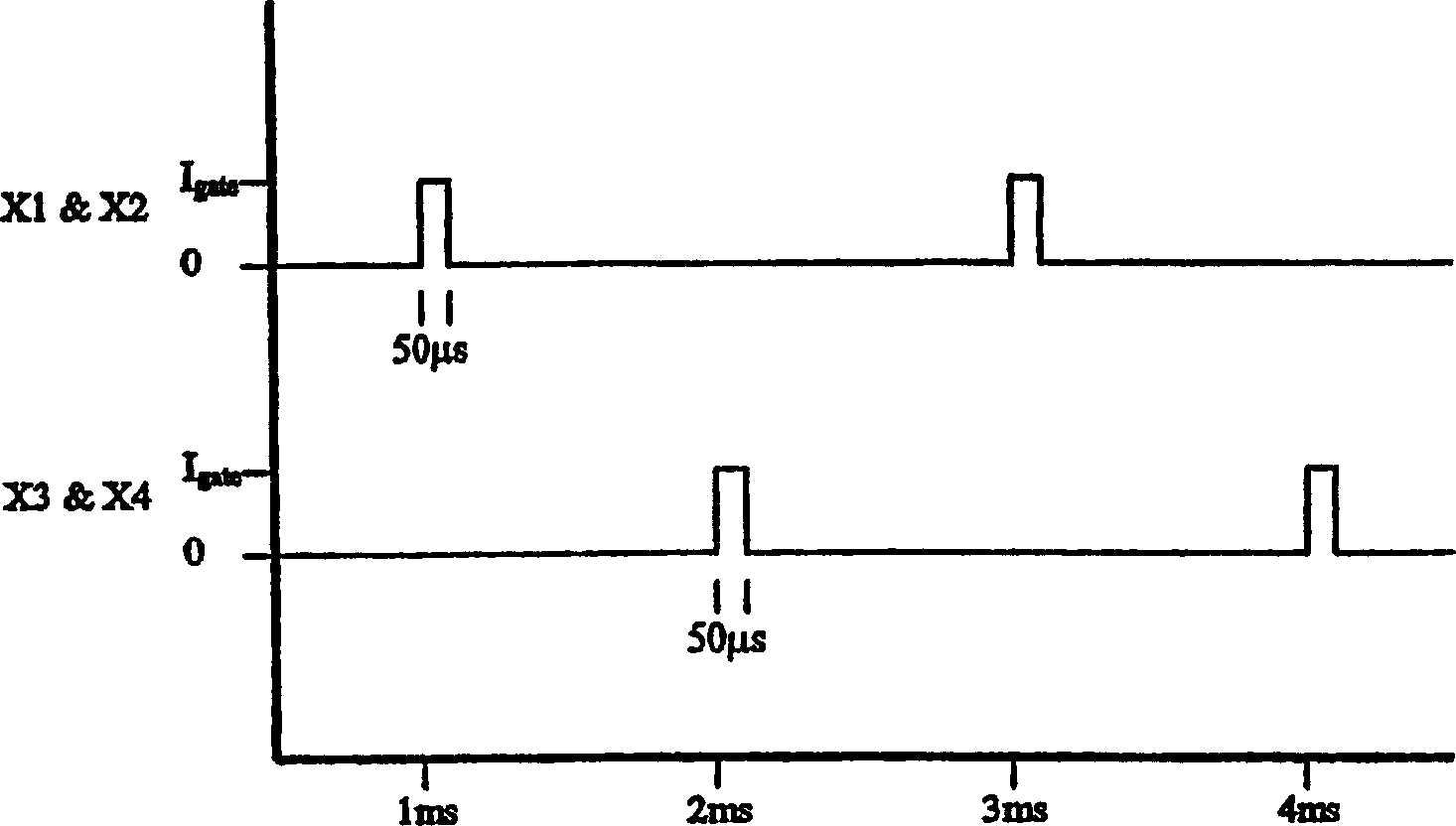

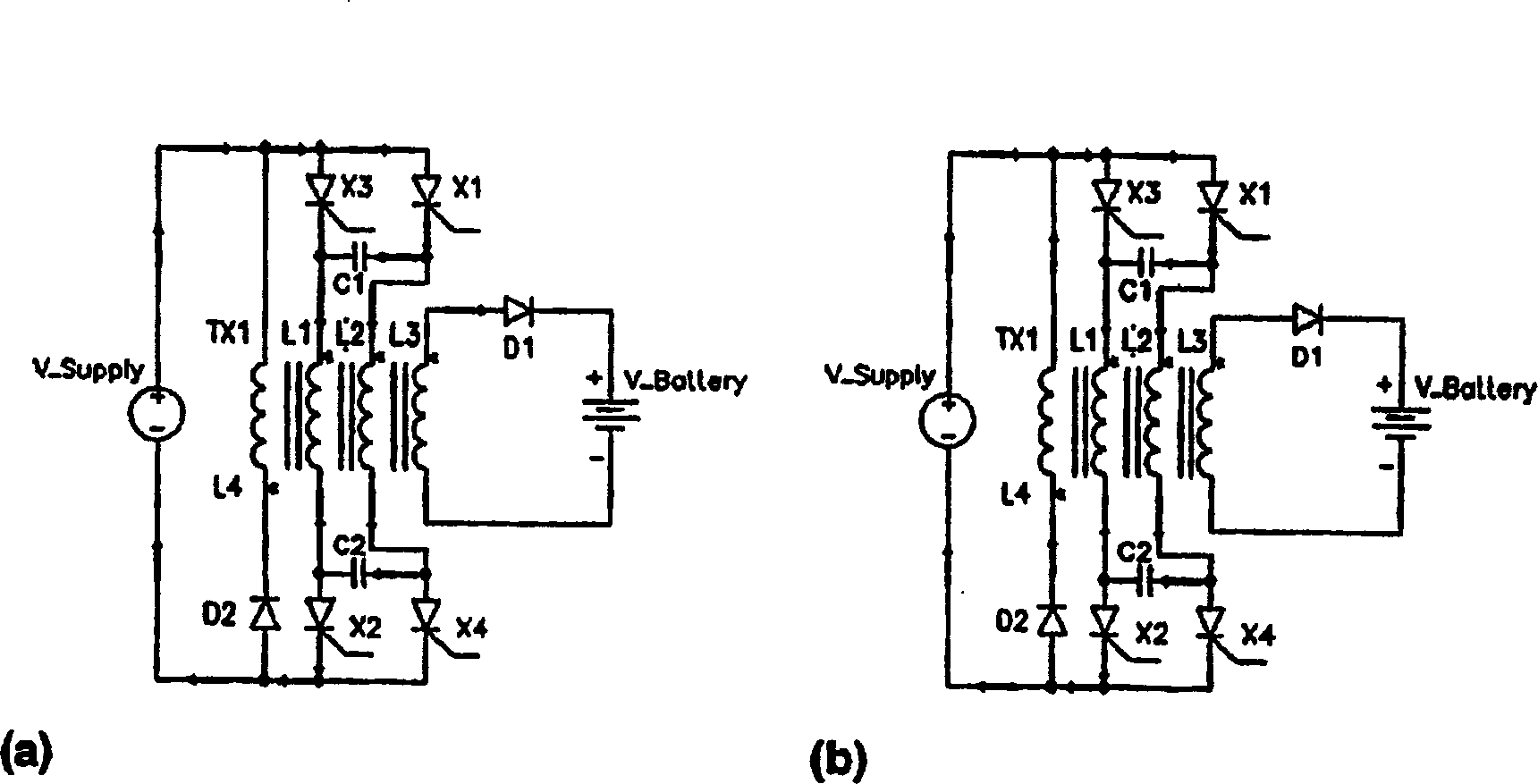

[0041] Figures 1a to 2 f shows a first preferred embodiment of the invention. The circuit shown in these figures comprises a transformer TX1 with four separate coils L1, L2, L3 and L4. L1 is connected to the DC supply voltage via two thyristors X2 and X3 at both ends of the coil. L2 is likewise connected to the DC supply voltage via two thyristors X1 and X4. For example, the first ends of the L1 and L2 coils, starting ends (use * to mark) are connected together through a capacitor C1, and the other ends of the L1 and L2 coils are connected together through a second capacitor C2. The anodes of the thyristors X1 and X3 are connected to the positive terminal of the DC power supply, and the cathodes of X2 and X4 are connected to the negative terminal of the DC power supply. The gates of the thyristors X1, X2, X3 and X4 are controlled by a conventional pulse generator (not shown). A typical firing pulse for the gates of thyristors X1, X2, X3 and X4 is given by Figure 1b sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com