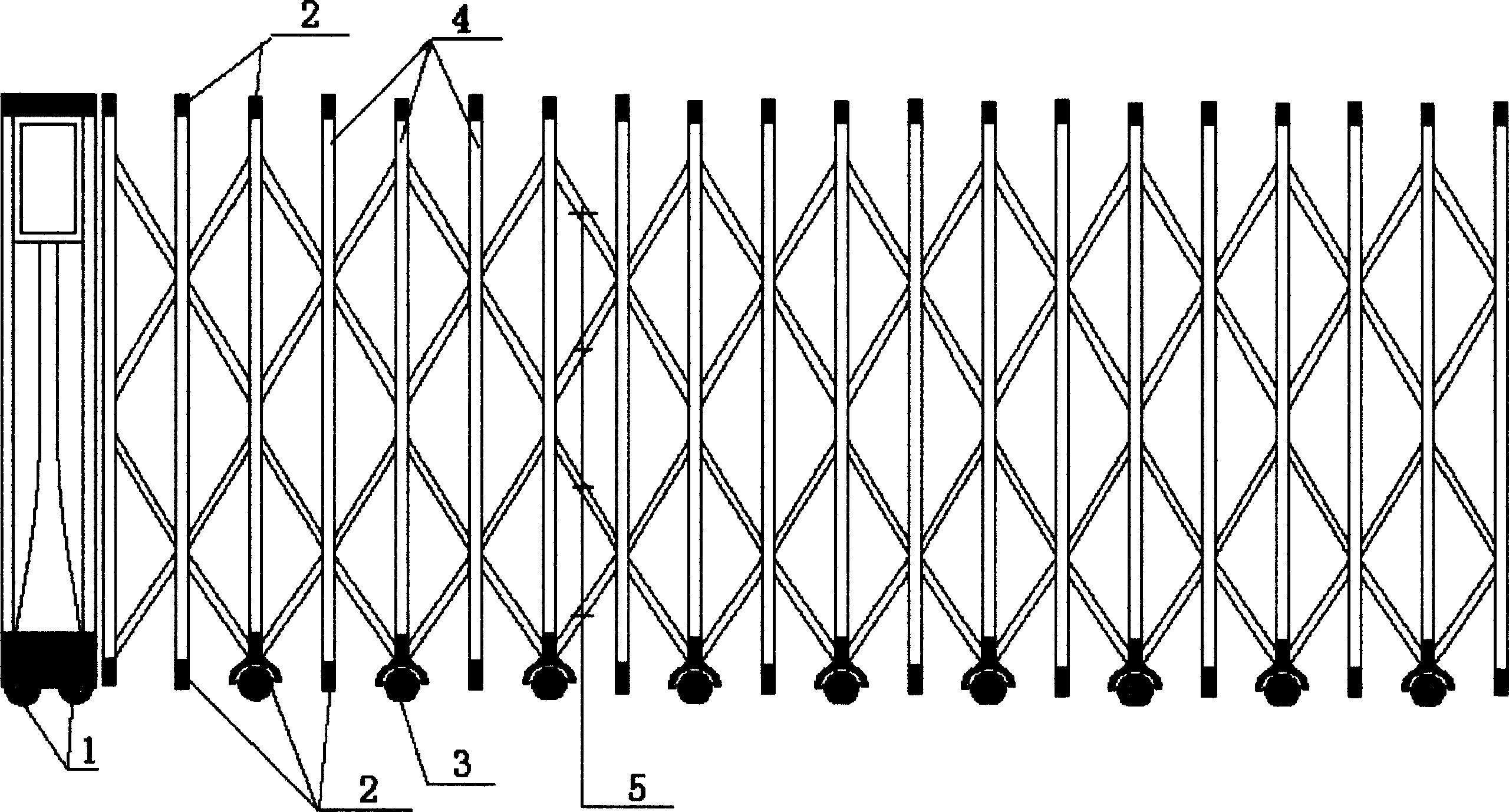

Electric telescopic door

An electric telescopic, door row technology, applied in the direction of gates/doors, lighting devices, lighting device parts, etc., can solve problems such as affecting the aesthetic effect of doors, opaque materials, single color, etc., to achieve perfect appearance, low cost, line smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Use polymethacrylate or plexiglass rods and plates, and cut according to the size required by the drawing. After laying down the connecting rod material and door discharge, carry out mechanical processing, drilling, threading the rod, cutting two sides and three knife ends (matching light source cover), washing tank (connecting rod guide groove). After processing, start to assemble the connecting rod and the door row. When assembling the door row, install the LED variable light source on the upper and lower end faces of the door row (install 4 groups, upper 2 groups, and lower 2 groups for one door row) and connect the power cord to each On the light source group, the installation is completed and the debugging is qualified before leaving the factory. The program is characterized by fast processing speed and simple process.

Embodiment 2

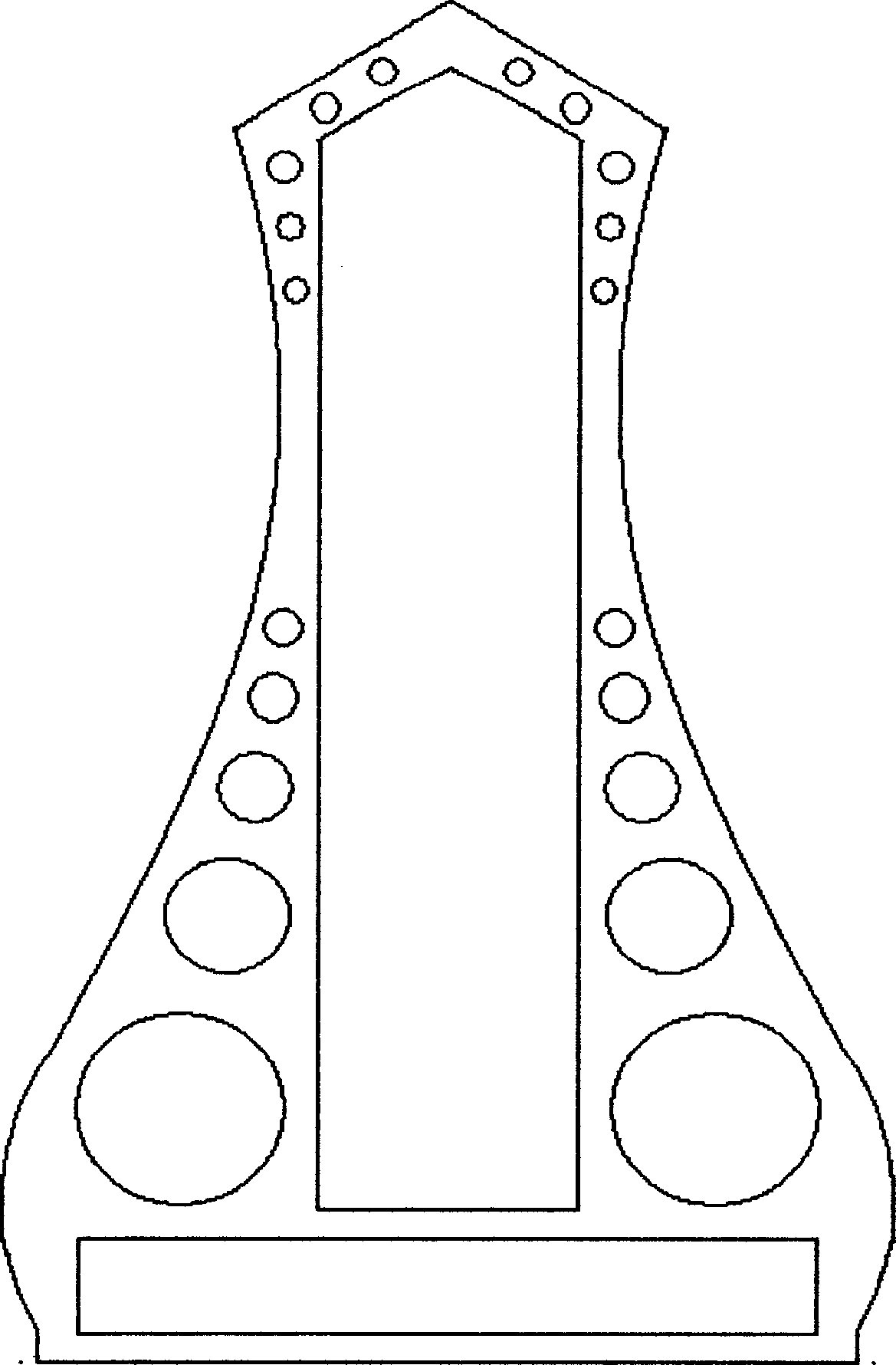

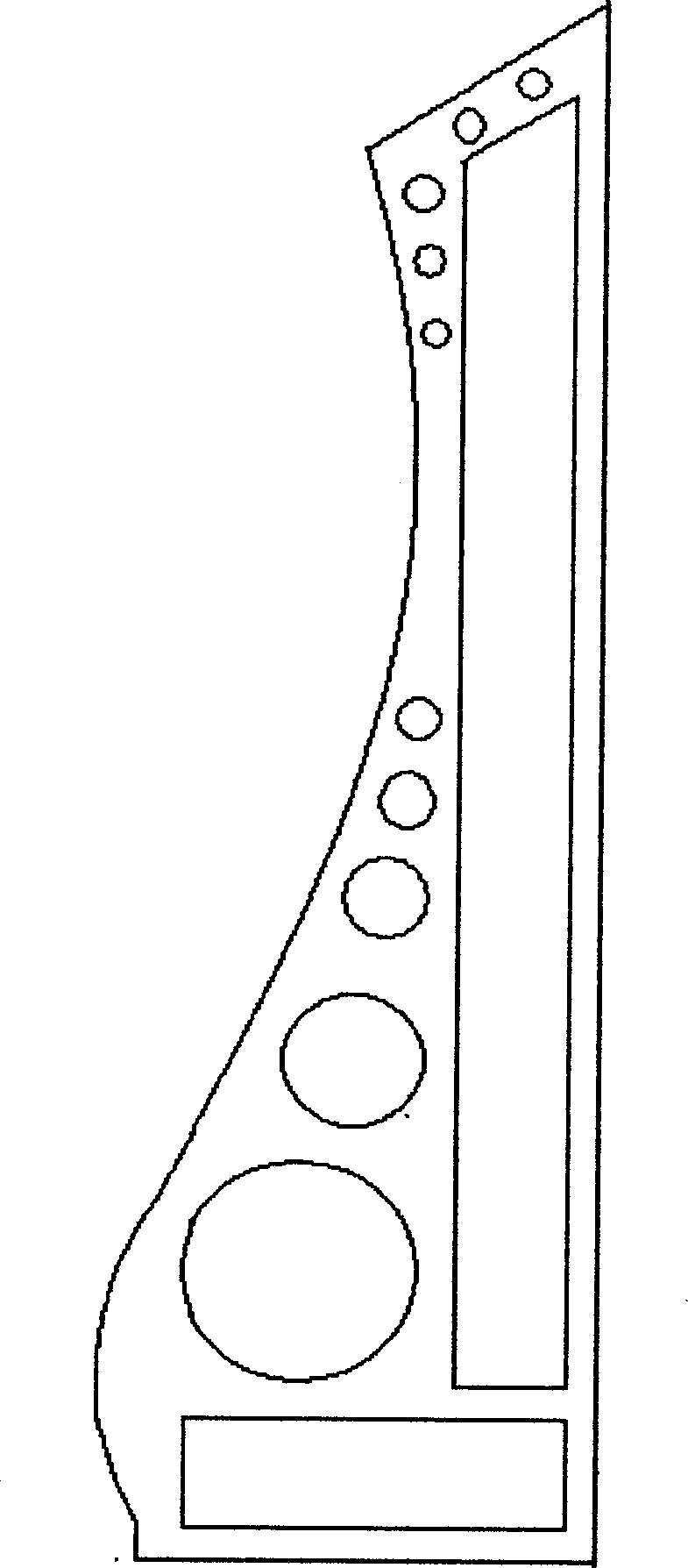

[0014] Using casting technology, heat the designed door row and connecting rod mold to 60°C, inject liquid polymethacrylate raw materials, open the mold after forming, and carry out grinding, repairing and other processes. After passing the mold, assemble it into a complete set. The shape can be as figure 2 or image 3 The shapes shown, other shapes are also possible. Assemble the LED power supply on the casted finished door row or connecting rod for debugging, and leave the factory after passing the test.

Embodiment 3

[0016] Choose CNC equipment such as water jet engraving machine and grinding machine for standard product processing.

[0017] Fix the polymethacrylate or plexiglass plate on the waterjet engraving machine, carry out standard processing according to the designed various door rows and connecting rod shapes, and leave the factory after processing and passing the installation and debugging. The characteristic of this scheme is that it can process doors with more complex shapes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com