Coupling head with detachable front plate, for railway vehicles, and corresponding mounting method

A technology of transportation tools and coupler heads, which is applied in the field of coupler heads, can solve the problems of high processing cost, cost increase, high manufacturing and warehousing cost diversity, etc., and achieve the effect of reducing noise level, reducing noise and reducing troubles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

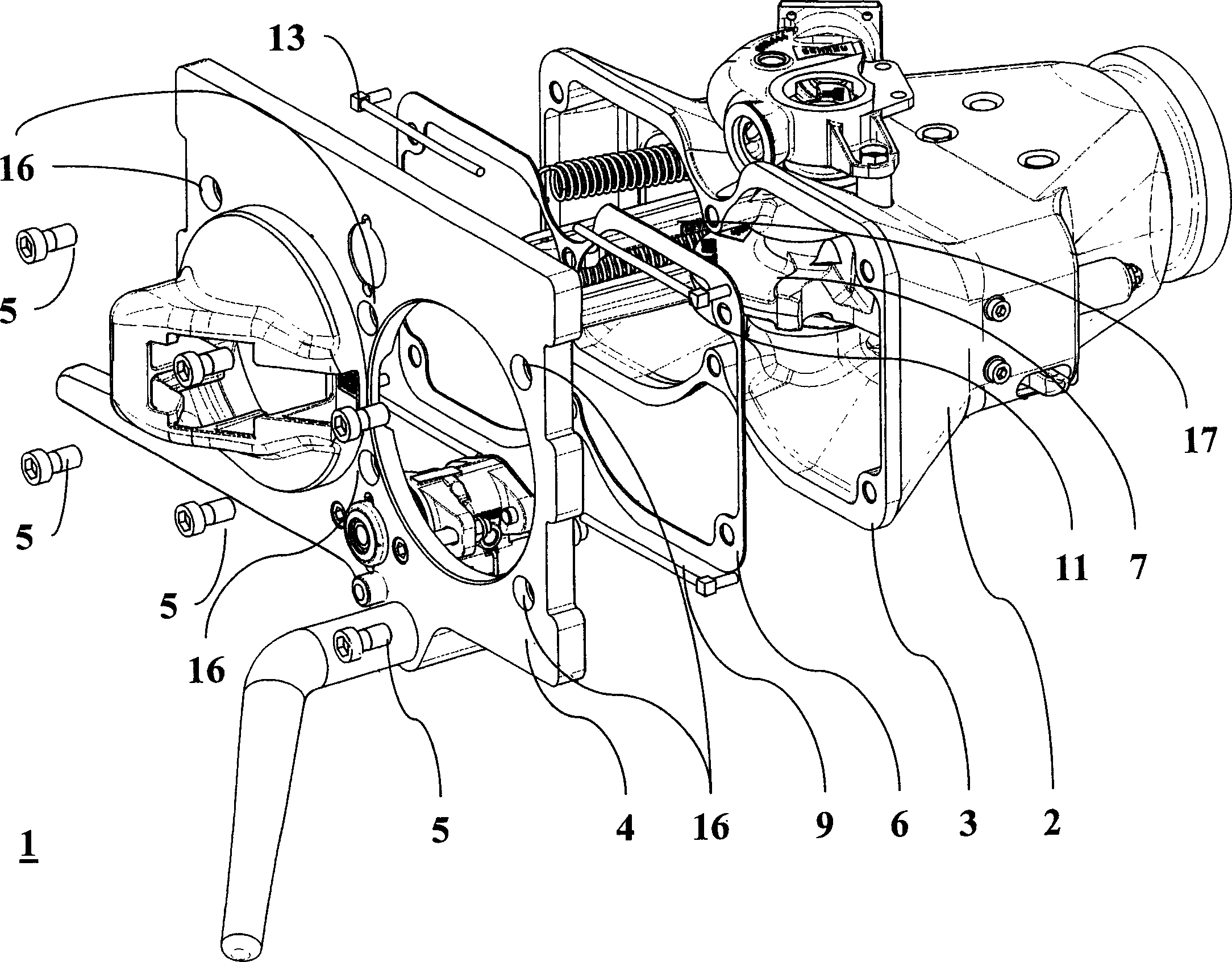

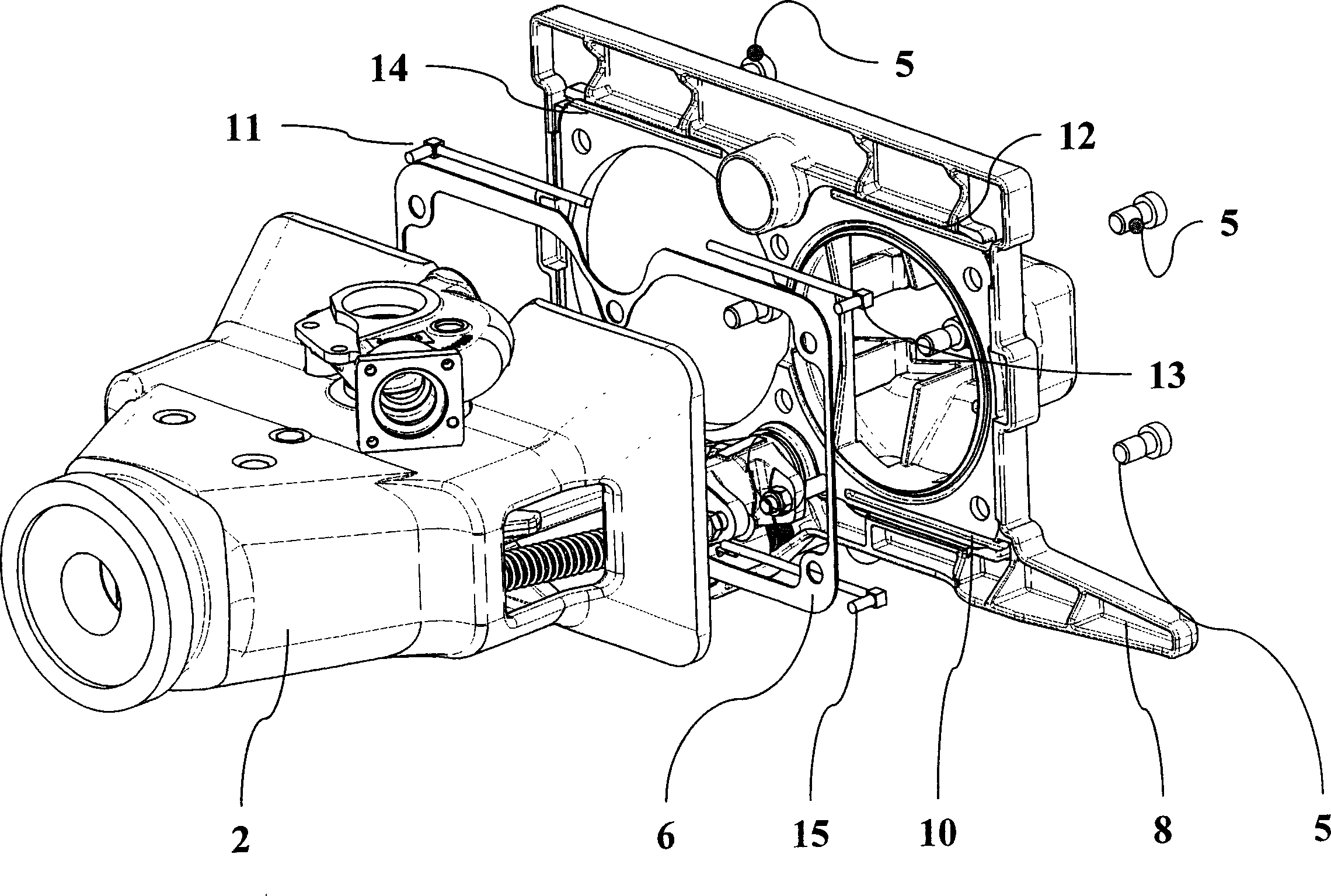

[0046] Hereinafter, specific embodiments of the device of the present invention will be further described in detail with reference to the accompanying drawings.

[0047] figure 1 Shown is the structure of a coupler head 1 that can be understood with a standard assembly structure, which has two basic components: a faceplate 4 and an actual coupler head housing 2 . A correction member 6 may be provided between the coupler head housing 2 and the faceplate 4 . Said correcting member 6 is used to compensate or eliminate any difference that may exist between the coupler head housing 2 and the facing face of the faceplate 4 . Such as figure 1 As shown, the correction member may be a correction plate 6 . Furthermore, a backing member (not shown), such as a backing member formed as a shim, may additionally or alternatively be used. Needless to say, the correcting member and the pad member are not structural components of the device of the present invention.

[0048] Further compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com