Backwash filter

A filter and backwashing technology, which is applied in the field of filters, can solve problems that need to be proven in practice, and achieve the effect of eliminating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

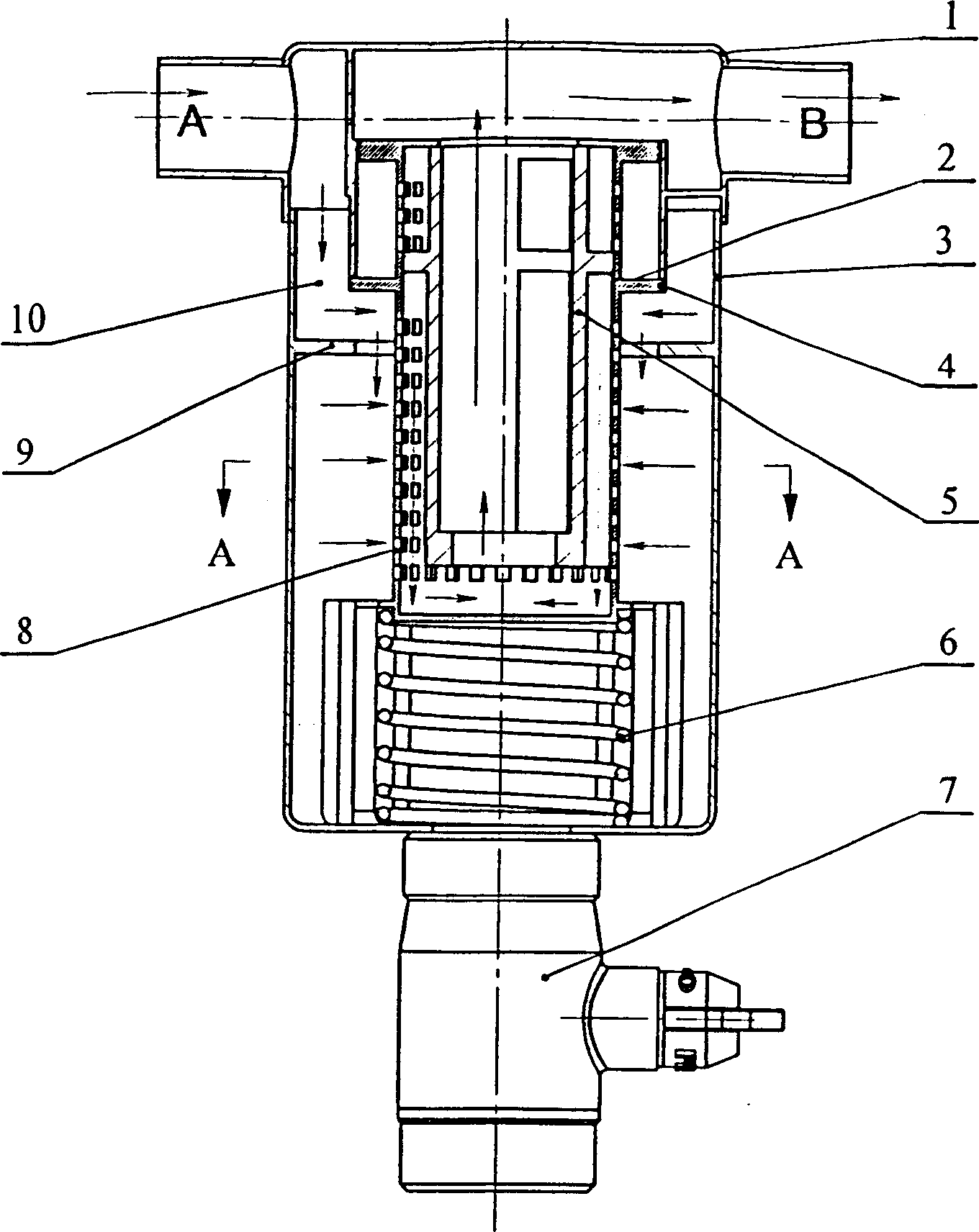

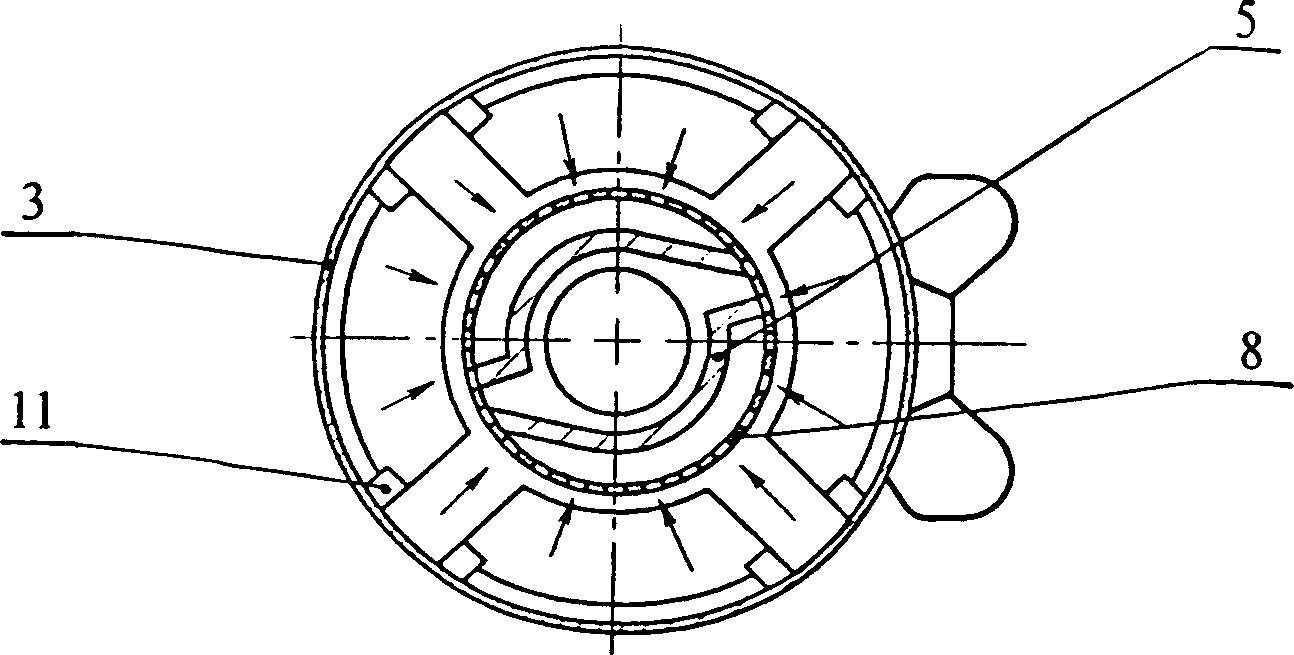

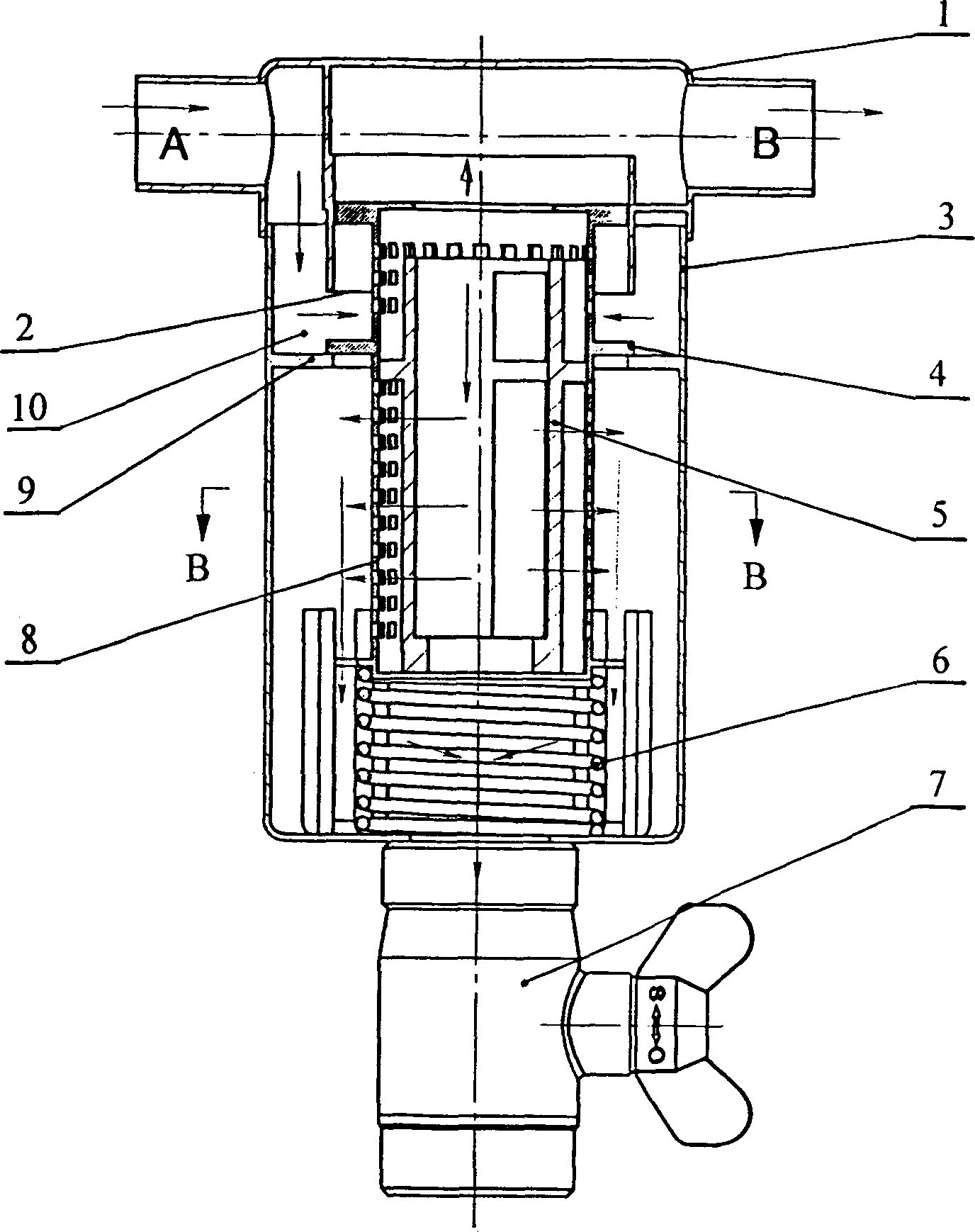

[0012] The embodiments of the present invention will be further described below in combination with the above-mentioned drawings.

[0013] see figure 1 -4. The backwash filter has a barrel-shaped shell 3. The sewage outlet at the bottom of the shell is connected to an openable and closable ball valve 7. There are 4 pairs of upwardly extending guide walls 11 evenly distributed on the inner bottom, and a spacer ring is arranged on the inner upper part. 9. The top is open. The upper cover 1 is fixed on the top of the housing. The two ends of the upper cover are medium inlet A and outlet B respectively. The inlet A communicates with the housing to form a flow channel 10. The upper cover is provided with a lower port 2 extending into the inner cavity of the housing. There is a filter screen 8 inside the housing, which is radially positioned in the guide wall of the housing and can move up and down without turning. The bottom of the filter screen is closed, and a spring 6 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com