Pulse self-cleaning type air filter

An air filter, self-cleaning technology, applied in the direction of dispersed particle filtration, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of short service life, high air leakage rate, poor flushing effect, etc., and achieve long service life, Good sealing performance and good flushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

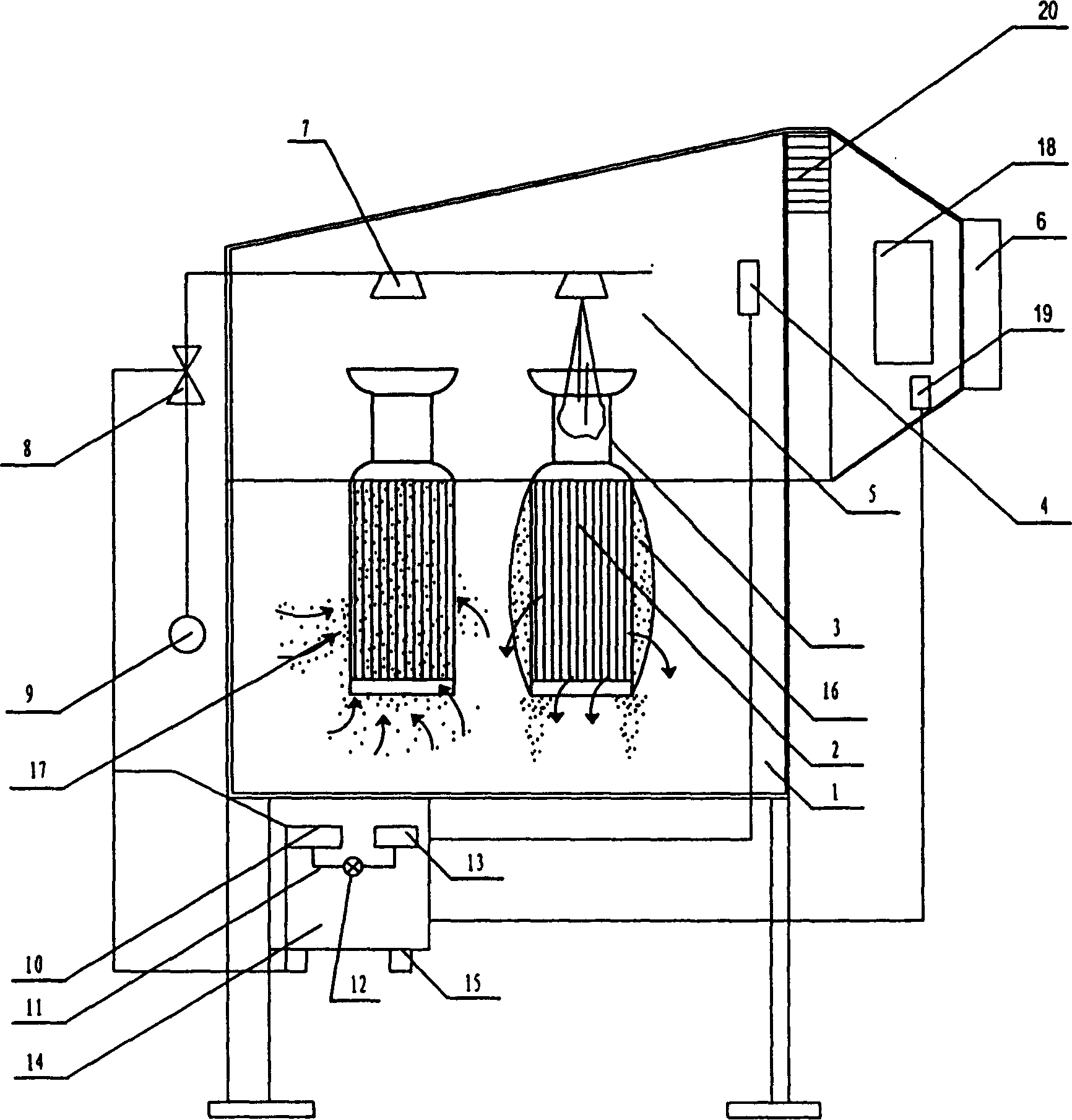

[0008] Control attached figure 1 , its structure includes four parts: filtration, self-cleaning, control, and pressure protection, among which the filtering part is three-stage filtering, the first-stage filtering is set in the filter screen in the dust and gas box 1, and the second-level filtering is set in several parallel installations in the box. Each filter cartridge 2 is set corresponding to the self-cleaning air source nozzle 7 in the self-cleaning part, and the third-stage filter is arranged in the three-stage filter box 20 in the clean air outlet pipe 6, and the three-stage filter box 20 is located in the clean air outlet pipe 6. After the secondary filtration; each Venturi tube 3 in the self-cleaning part is correspondingly arranged above the filter cartridge 2, and each Venturi tube 3 is connected to the filter cartridge 2 correspondingly, and the Venturi tube 3 is arranged in the sealed box 5, Negative pressure collection point 4 is connected to the power control b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com