Vibration damping and sheet type ballastless track

A technology of ballastless track and slab type, which is applied in the direction of track, road, building, etc., can solve the problems of high construction cost, difficulty in substructure renovation, slow construction speed, etc., and achieve good environmental protection, high promotion and application value, and high durability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

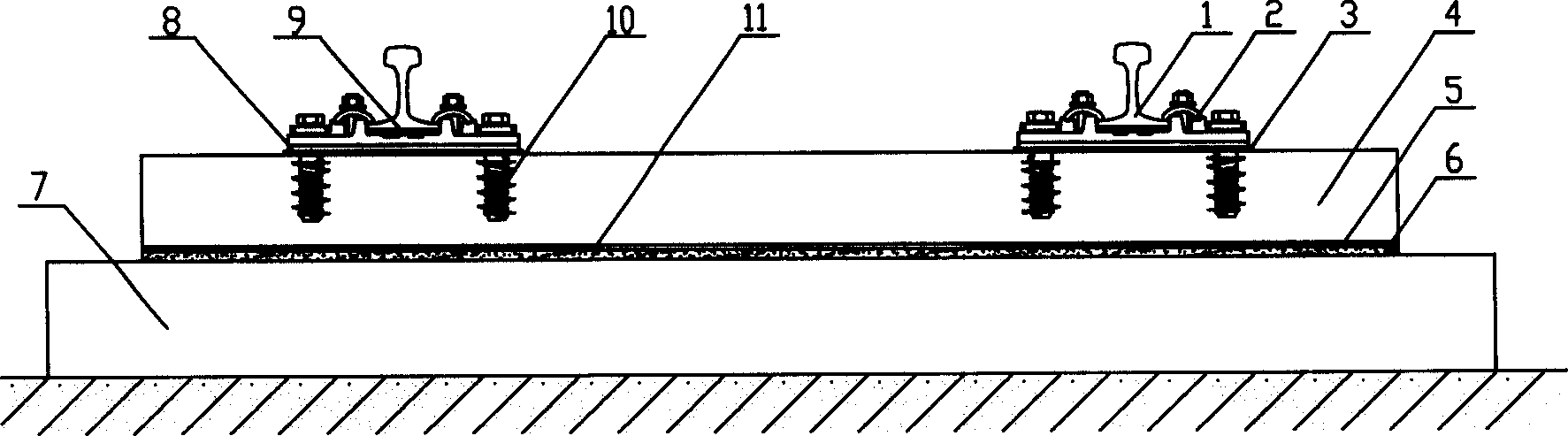

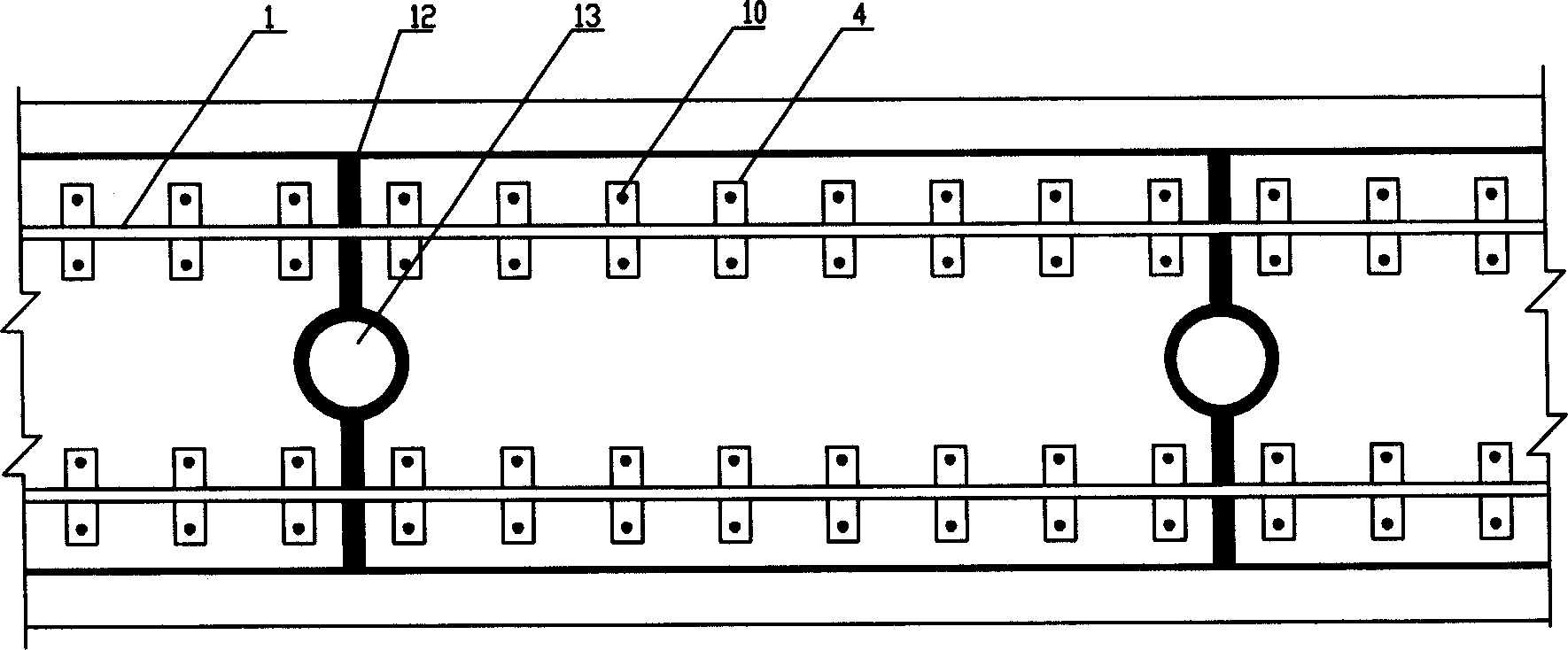

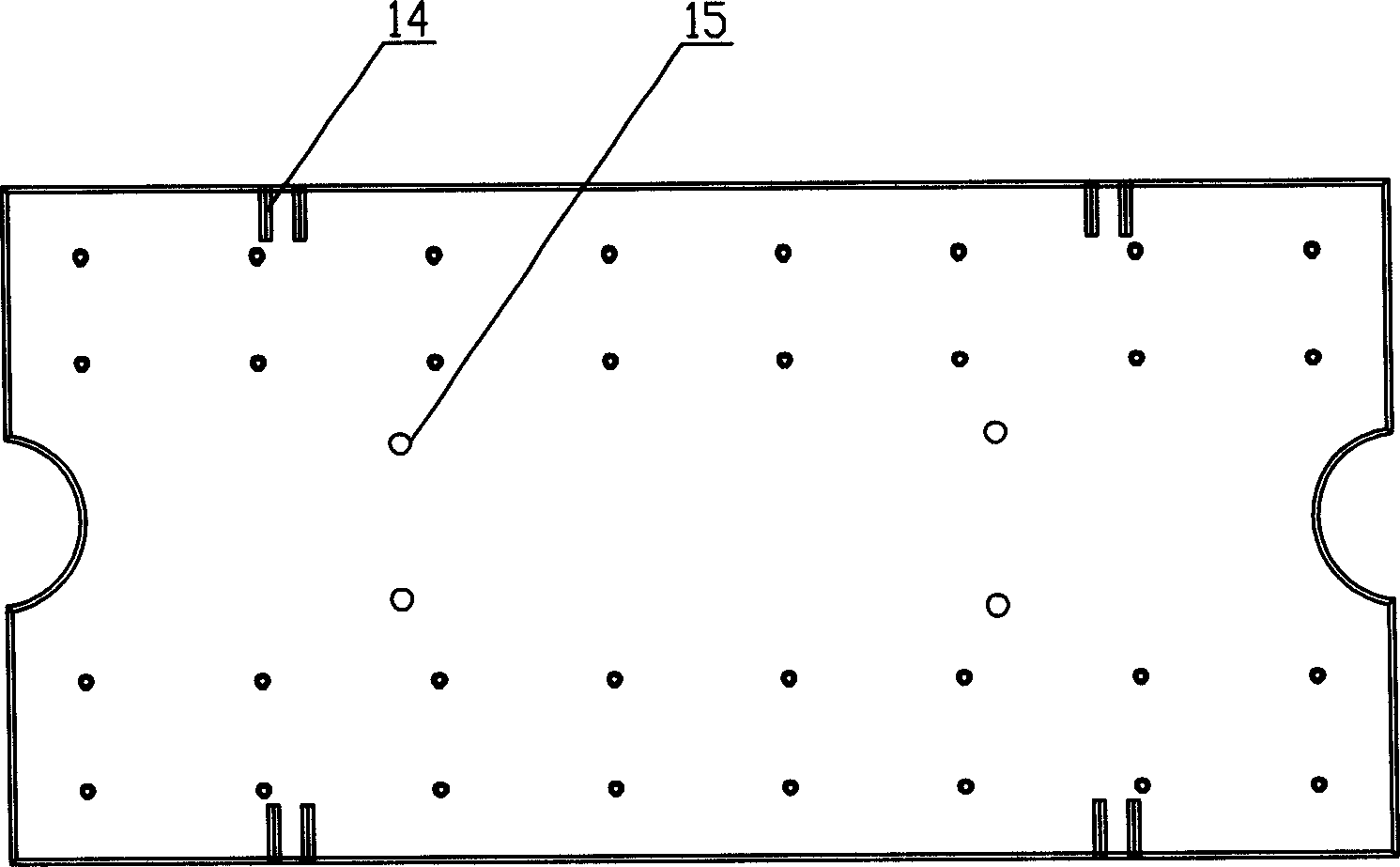

[0027] Such as Figure 1 to Figure 7 As shown, a vibration-absorbing plate type ballastless track, the base 7 is set on the foundation, the longitudinal centerline of the base 7 coincides with the centerline of the line, and a circular convex stopper 13 is installed on the base, and the convex stopper 13 There is a track plate 4 between them and the longitudinal centerline of the track plate coincides with the center line of the line. A CA mortar adjustment layer 6 is provided between the track plate and the base, and the CA mortar adjustment layer 6 is tightly connected with the track plate. Between the adjustment layer and the track slab and at the bottom of the track slab at the lower part of the rail, an elastic rubber backing plate 5 is also provided, and between the CA mortar adjustment layer and the track slab and at the bottom of the track slab in the middle of the line, a foamed polyethylene hollow material 11 is arranged, The middle part of the longitudinal ends of t...

Embodiment 2

[0029] Such as Figure 8 As shown, the slab ballastless track of the present invention is installed on the protective layer on the bridge; others are the same as in Embodiment 1.

Embodiment 3

[0031] Such as Figure 9 As shown, the slab ballastless track of the present invention is installed on the tunnel invert in the tunnel; others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com