Integrally cast grate plate

An integral casting and grate plate technology, which is applied in grain processing and other directions, can solve the problems of difficulty in particle size distribution of products, difficulty in ensuring product particle size, and difficulty in processing grate bars, so as to facilitate follow-up operations, good stress conditions, and prolong life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

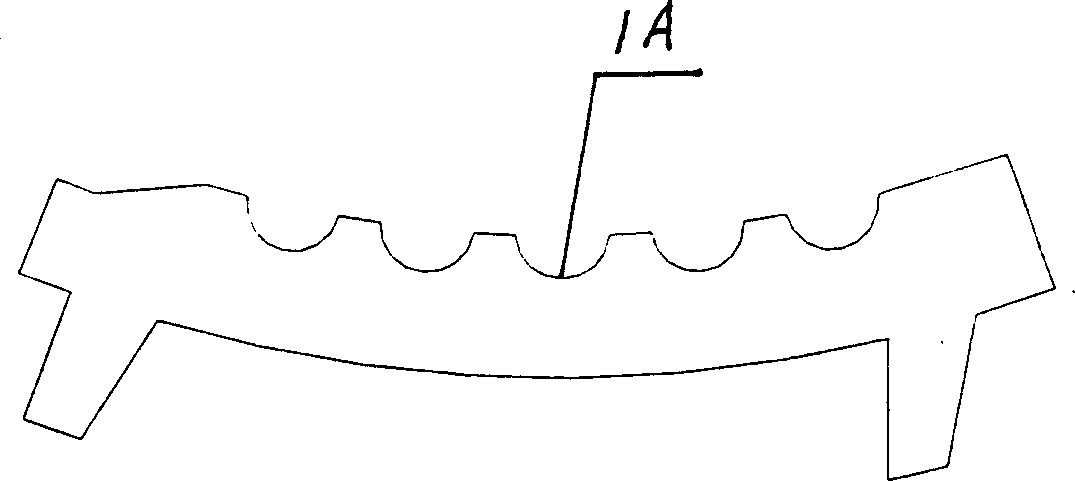

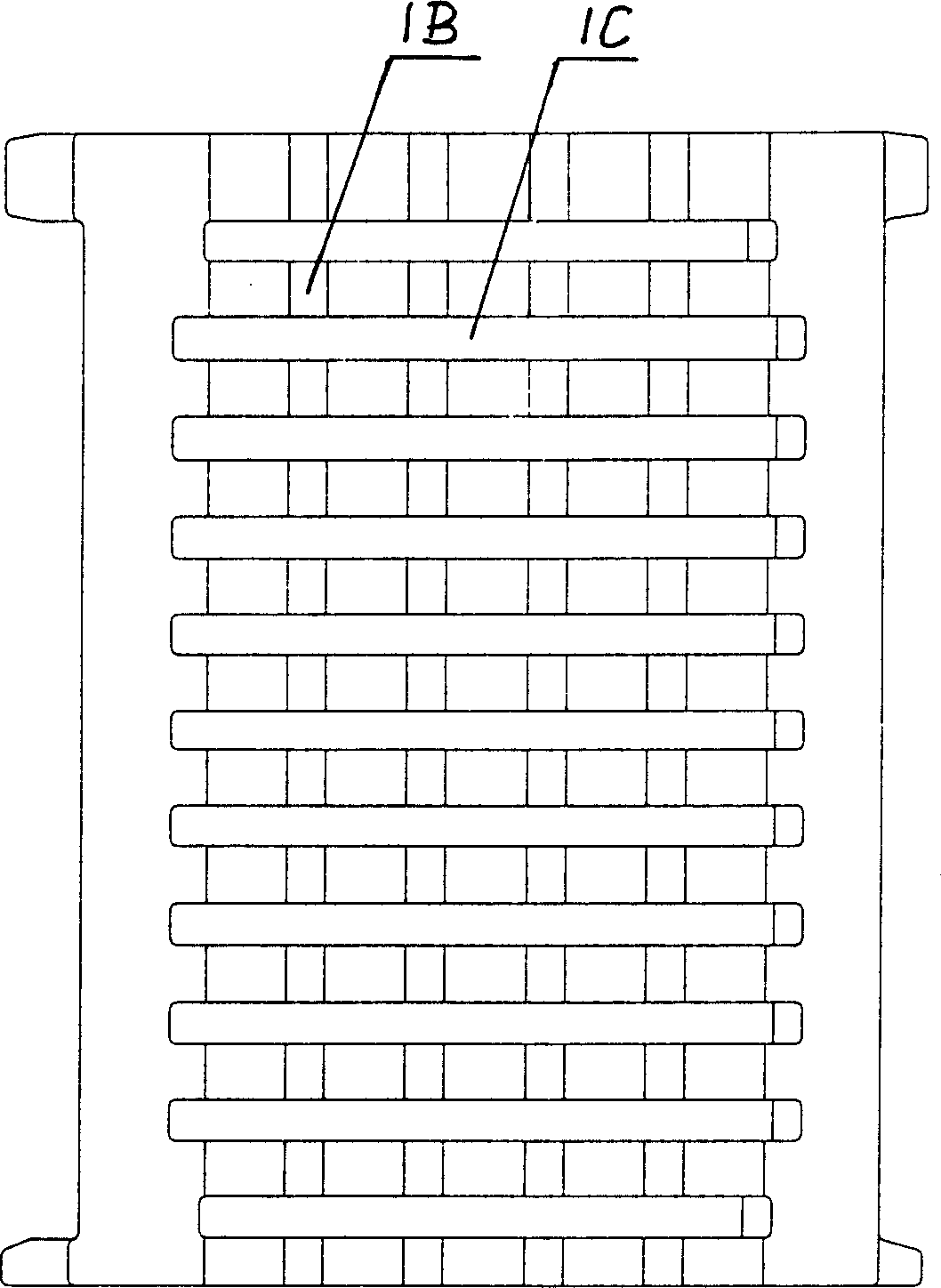

[0010] see figure 1 and figure 2 , a grate plate with integral casting and a grate bar and a grate slot, in the vertical direction of the grate slot 1C formed between the grate bar 1B and the grate bar 1B, there are semicircular concave teeth arranged in an orderly shape 1A.

[0011] The working principle of the present invention is that when the material flow is between the grate and the rotor, since the grate plate is cast with regular semicircular concave teeth in the transverse direction, the chance of the material being hit between the grate and the rotor is increased, and part of the material is here The area is further crushed and then discharged from the grate slot. Compared with other types of discharge grates, this kind of grate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com