Methods of treating deposition process components to form particle traps, and deposition process components having particle traps thereon

A particle capture and particle technology, applied in cleaning methods and utensils, chemical instruments and methods, manufacturing tools, etc., can solve problems such as performance degradation and weak adhesion in particle capture areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

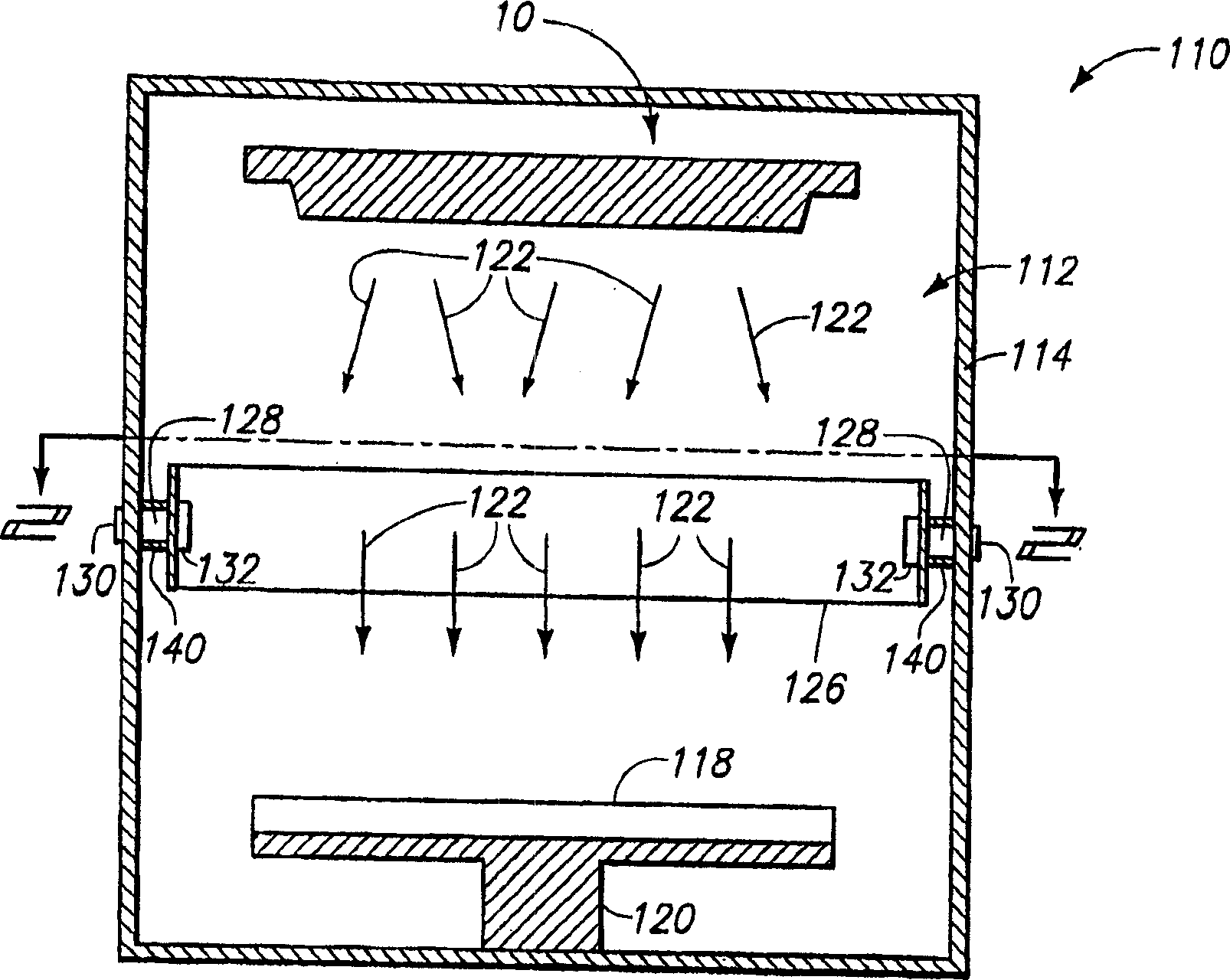

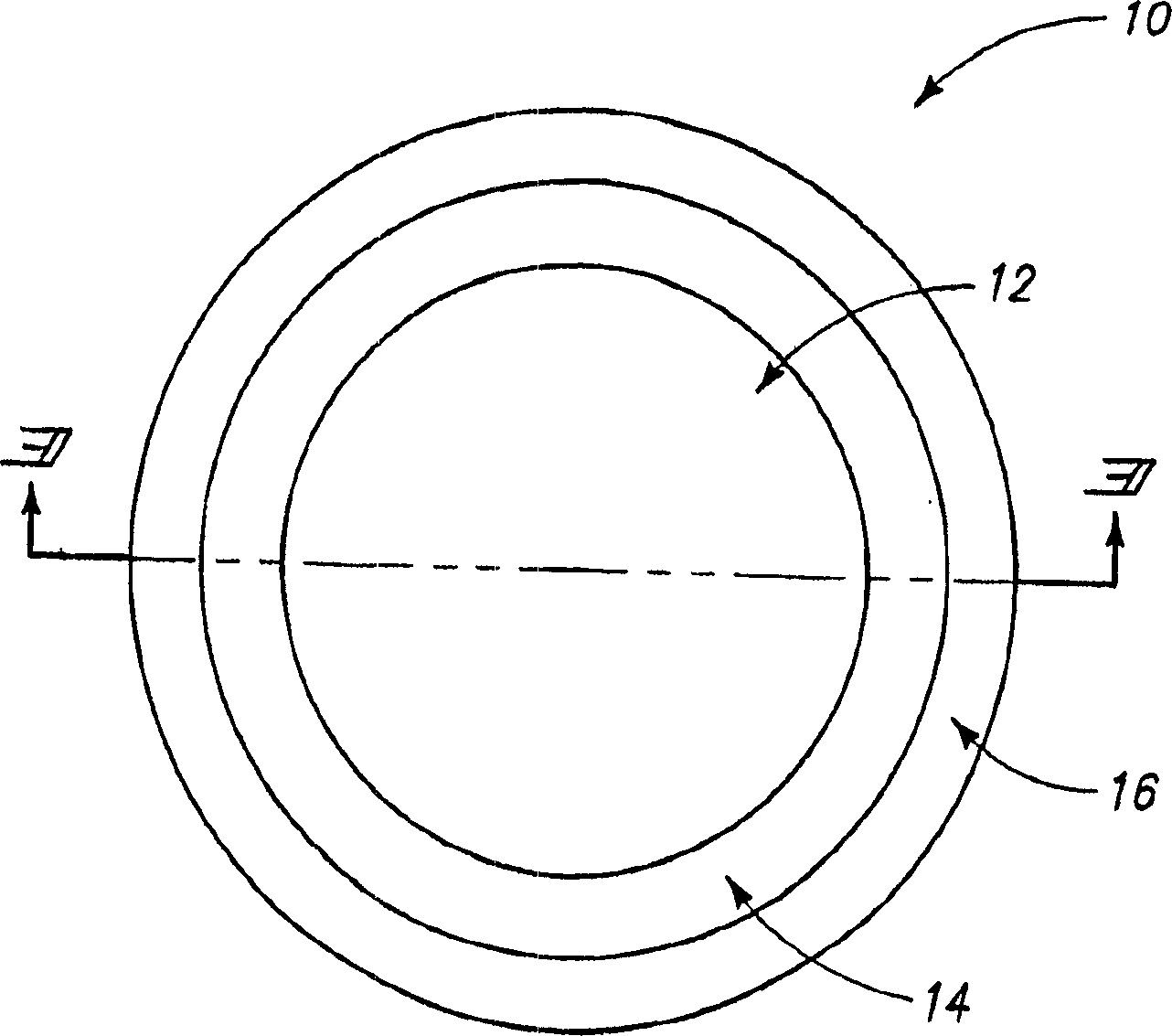

[0032] The present invention includes particle trapping regions that may be formed on one or more surfaces of physical vapor deposition components, and methods of forming the particle trapping regions. The particle trapping region can be used to trap material deposited on the part during the deposition process.

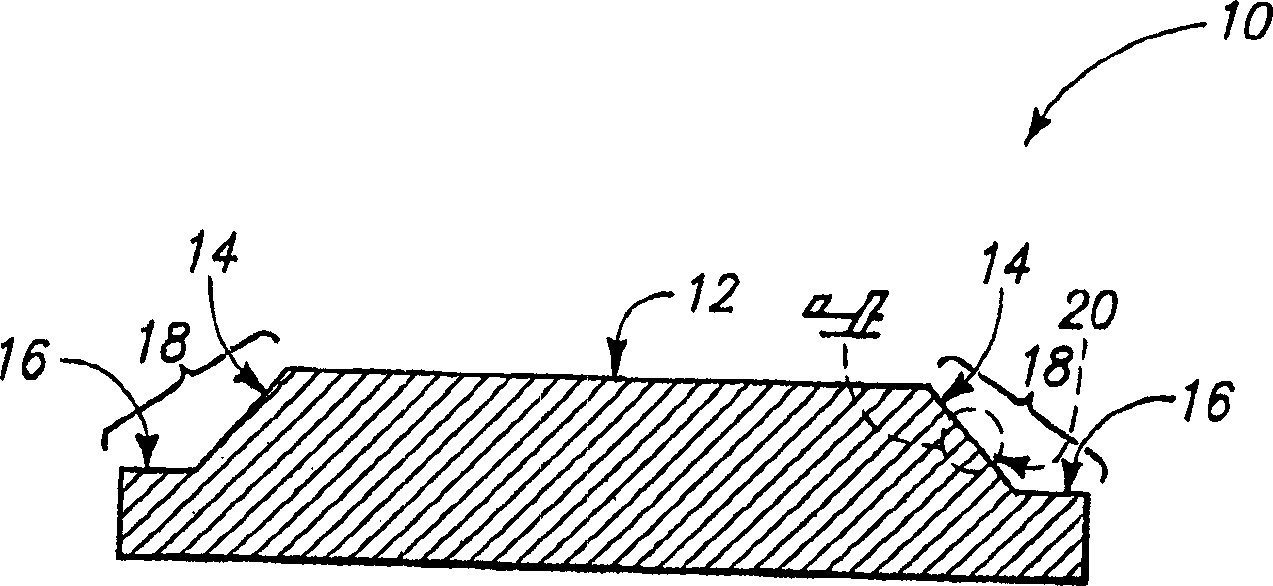

[0033] The particle trapping region is formed by bead blasting, and in some aspects machining, one or more surfaces of the physical vapor deposition component. If the processing component is a sputtering target, the processing surface may include various non-sputtering surfaces, such as sidewall surfaces, flange surfaces, and / or non-sputtering surfaces along the sputtering plane.

[0034] Protrusions formed by machining may be considered to correspond to macro-scale roughness, and roughening by bead blasting may be considered to correspond to micro-scale roughness. Thus, the present invention may include patterns having one or both of macroscale and microscale roughn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com