Supercritical CO2 extraction method of ganderoma lucium oil

A technology of Ganoderma lucidum spore oil and Ganoderma lucidum spore powder, which is applied in the direction of medical formula, medical preparations containing active ingredients, plant raw materials, etc., can solve the problems of ethanol flammability, complicated process, and complicated granulation process, so as to ensure natural activity , easy industrialization, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

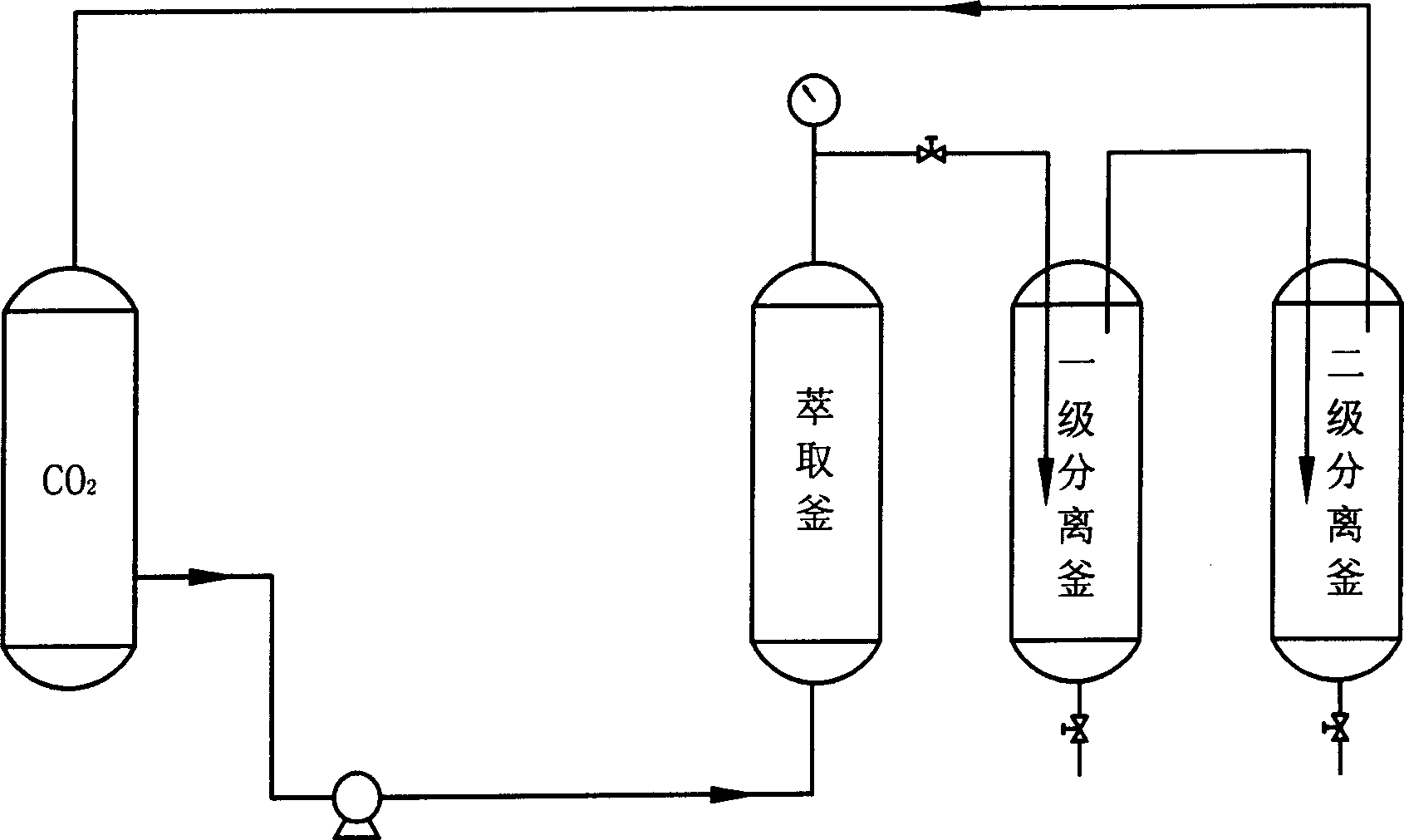

Image

Examples

Embodiment 1

[0018] Mix 4kg of Ganoderma lucidum spore powder and 3kg of crushed wood particles, put them into an extraction kettle, extract at 28MPa, 40°C for 3 hours, release 1150g of Ganoderma lucidum spore oil from the primary separation kettle, and the oil yield is 28.75%.

Embodiment 2

[0020] Mix 4kg of Ganoderma lucidum spore powder and 2.5kg of glass beads, put them in an extraction kettle, extract at 28MPa, 40°C for 3h, release 1030g of Ganoderma lucidum spore oil from the primary separation kettle, and the oil yield is 25.75%.

Embodiment 3

[0022] Mix 4kg of Ganoderma lucidum spore powder and 2kg of stainless steel filler, put it in an extraction kettle, extract at 35MPa, 40°C for 3h, release 1200g of Ganoderma lucidum spore oil from the primary separation kettle, and the oil yield is 30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com